Huarong’s 2025 Overview: Injection Molding Innovation, Global Trust, and Our Vision for 2026

2025-12-30 10:49:46

As 2025 draws to a close, we at Huarong Group look back on a year shaped by three key themes:

- Stronger global market positioning – especially in India’s anti-dumping environment.

- Deeper technology innovation – from microcellular foam to advanced color effects and co-injection.

- Closer partnerships with customers – reflected in real application cases and highly engaged website content.

This overview summarizes the milestones that defined our year and how they reinforce our long-term commitment to being a reliable injection molding machine and turnkey solution partner.

In 2025, global manufacturers faced challenges from trade policies, cost pressures, and supply chain restructuring. Against this backdrop, we focused on building structural advantages for our customers, starting with compliance and pricing stability in key markets, and extending to our presence at major international exhibitions.

In 2025, India implemented anti-dumping tariffs on plastic processing machines imported from several countries. After a formal review and evaluation, Huarong became one of the few suppliers confirmed with a 0% anti-dumping duty rate.

For our Indian customers and partners, this result means:

- No additional anti-dumping cost burden on machines supplied by Huarong.

- More predictable investment planning, since temporary tariff surcharges do not distort pricing.

- Long-term competitiveness when expanding capacity or upgrading existing equipment.

This 0% result is not only a price advantage. It also reflects our compliant documentation, transparent cost structure, and long-term presence in the Indian market. For buyers, it is a strong signal that Huarong is a stable and trustworthy long-term equipment partner, not a short-term low-price supplier.

Further reading: Navigating India's 2025 Anti-Dumping Tariffs: How Huarong Secures Your 0% Advantage

At K Show 2025 in Germany, we focused on one message: Huarong is not just a machine builder – we deliver complete injection molding projects.

Our booth showcased:

- Injection molding equipment: carefully selected double injection molding machines tailored to the displayed application.

- Customer-specific mold integration: real production molds developed with partners to reflect true factory conditions.

- Automation systems: robots, transfer mechanisms, assembly devices, inspection, and packaging equipment configured as a single turnkey solution.

- Unmanned full-automatic workflow: from injection to part handling, assembly, quality control, and final packing – all running in a continuous cycle.

Related product: Fully Automated Hair Clip Production Line

This live demonstration attracted many visitors who were not only looking at machine tonnage or shot weight but also at how quickly they could achieve stable mass production with fewer operators and lower risk.

The positive feedback we received at K Show confirmed that customers increasingly expect:

- One partner to coordinate machines, molds, and automation.

- Proven experience in project planning, on-site commissioning, and long-term service.

In 2025, this exhibition helped position Huarong clearly as a turnkey project partner for global manufacturers.

Related articles: Successfully Concludes K Show 2025, Showcasing Injection Molding and Automation

Technology innovation remained at the heart of Huarong’s strategy in 2025. We focused not only on machine hardware, but also on new processes and applications that directly help customers reduce weight, save energy, and differentiate their products through design and appearance.

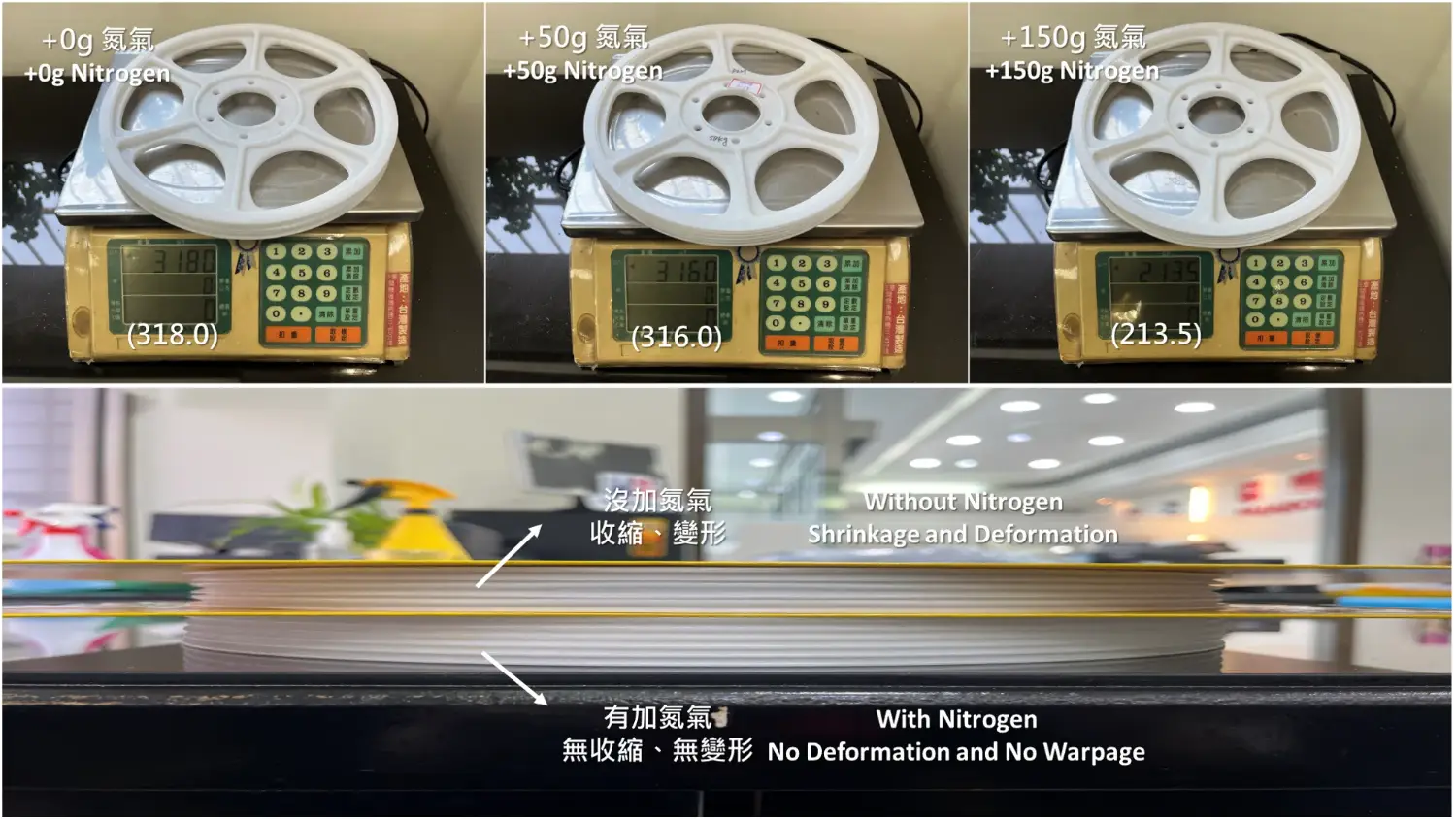

This year, we continued to promote Microcellular Foam Injection Molding as a key technology for customers seeking lightweight, energy-efficient production.

Microcellular foam injection molding introduces supercritical gas (such as nitrogen or CO₂) into the polymer melt, creating uniform micro-bubbles during injection. This achieves:

- Weight reduction of approximately 15–20% for many products, depending on design and material.

- Lower injection pressure and clamp force requirements reduce equipment stress and extend machine life.

- Shorter cycle times and improved dimensional stability on thick or structurally complex parts.

- ESG-friendly production, since the process can reuse materials and reduce total plastic and energy consumption.

In 2025, we moved beyond “concept promotion” and worked with customers to put microcellular foam technology into real production lines, especially in applications like:

- Structural components that can tolerate slight surface changes but benefit from weight reductions.

- Large parts where clamp tonnage, energy use, or cycle time were previously a bottleneck.

The dedicated article “Microcellular Foam Injection Molding: A Complete Guide to Lightweight and Energy-Efficient Production” has become one of our cornerstone technical references for customers planning future ESG and cost-reduction projects.

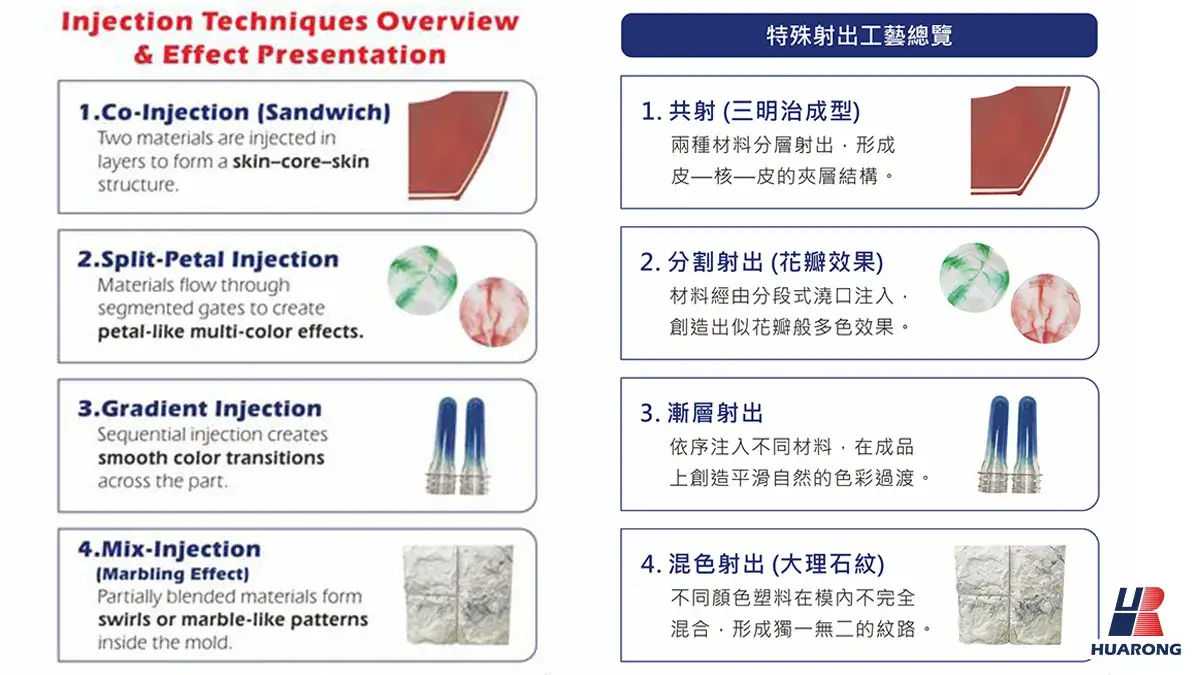

Another core focus in 2025 was our multi-color, multi-material molding capability, combining:

- Co-injection (sandwich) molding

- Segmented or petal-like color separation

- Gradient injection

- Mix-injection for marbling / swirl effects

Through our Double Injection Molding Machine – HDC series and related solutions, we help customers create:

- Containers and consumer goods with distinct inner and outer materials (e.g. soft-touch surfaces, recycled core materials).

- Petal-style or zone-separated colors from a single mold, without additional painting or printing.

- Gradient and marbling effects that give products a premium, unique aesthetic while staying within standard injection cycles.

These technologies are closely connected to our in-depth articles, including:

- “Injection Molding Color Mixing and Marbling Effect: Process, Color Swirl Techniques, and Application”

- “Co Injection Molding: A Complete Technical Guide for Modern Plastics Manufacturing”

Together, they show how process design + mold design + machine control can deliver both functional performance and visual differentiation, helping customers stand out in competitive markets such as packaging, home appliances, and automotive.

Beyond machines and technology, 2025 was also a year where we documented more real customer success stories on our website.

Representative case studies include:

- “From Taiwan to Thailand — Expanding Global Manufacturing Power with Huarong”

- Showcasing how cross-border cooperation and equipment planning help a customer expand capacity from Taiwan to Southeast Asia while maintaining product quality and delivery reliability.

- “Build a Self-Reliant Bottled Water Line with Cap & PET Preform Injection Molding”

- Demonstrating how to transform from buying bottles from others to building an in-house PET preform and cap production line, with injection machines, molds, and planning for future bottle-blowing expansion.

- “Boost Automotive Parts Output with Smart Injection Molding Machines”

- Presenting how smart control, energy-efficient servo systems, and appropriate tonnage selection can significantly increase output for automotive components while stabilizing quality.

- “Beyond Injection Molding! Analyzing Successful Transformation Through Turn-Key Automation Solutions”

- Highlighting customers who upgraded not only machines but also automation, quality control, and internal logistics, turning their factories into more integrated, data-driven operations.

These are only some of the success stories listed on our Customer Base page, where more industries and applications are covered:https://www.huarong.com.tw/page/applications/en/customer_base/

Our website analytics for 2025 show clearly what our global audience cares about most: practical know-how and equipment planning. The following rankings are based on page views, reading time, and inquiries generated.

The following articles received particularly strong engagement:

- Injection Molding Machine Maintenance PDF and Checklist

- A structured guide and downloadable checklist to help factories implement daily, weekly, and periodic preventive maintenance on their machines.

- What is IML? In Mold Labeling Process, Benefits, and Applications

- An in-depth explanation of IML technology, processes, materials, and design considerations, together with related IML machine solutions.

- PET Preform Molding Solution: A Detailed Guide to PET Preform Manufacturing

- A complete overview of PET preform injection, from raw materials and tooling to dedicated PET injection molding machines.

- Injection Molding Business: A Complete Guideline of How to Start

- A long-form article guiding new investors on factory setup, equipment selection, cost planning, and future trends in the injection molding industry.

- How to Change a Mold? Mold Change Process for Efficient Mold Loading and Unloading

- A step-by-step guide for safe, efficient mold change procedures, which is especially helpful for custom molders and factories with frequent changeovers.

The popularity of these topics confirms that maintenance, process knowledge, business planning, and practical operating procedures are all crucial areas where customers rely on Huarong’s experience.

In terms of product interest, the top five English product pages were:

- Injection Molding Machine (General Series Overview)

- A key entry point for visitors to understand our full range of horizontal machines and application possibilities.

- https://www.huarong.com.tw/page/product/en/injection-molding-machine/

- Two-Platen Injection Machine – NRH Series

- Our flagship two-platen solution is especially attractive for large products, energy saving, and compact footprint requirements.

- https://www.huarong.com.tw/page/product/en/injection-molding-machine/single-injection/detail/two-platen/

- Vertical Injection Molding Machine

- Popular among customers focusing on insert molding, overmolding, and compact manufacturing cells.

- https://www.huarong.com.tw/page/product/en/vertical-injection-molding-machine/

- Double Injection Molding Machine – HDC Series

- Highlighting our co-injection and multi-component capabilities for dual-color, dual-material parts and aesthetic effects.

- https://www.huarong.com.tw/page/product/en/injection-molding-machine/multi-injection/detail/hdc-co-injection/

- PET Injection Molding Machine – PET Series

- Dedicated PET preform machines designed for high-output, stable quality bottle preform manufacturing.

- https://www.huarong.com.tw/page/product/en/injection-molding-machine/special-injection/detail/pet-bottle-preform/

This pattern shows a clear focus from buyers on core machine platforms (general, two-platen, vertical, multi-color) and PET packaging-related solutions, matching global trends in automotive, packaging, and consumer goods.

Looking ahead to 2026, we will continue to build on what we started in 2025—combining equipment, process expertise, and automation into complete solutions. Our roadmap can be summarized into three pillars.

Building on microcellular foam and energy-saving servo systems, we will:

- Expand lightweight and material-saving applications for more industries.

- Optimize machine configurations to reduce energy consumption per kg of product.

- Support customers in achieving their ESG and carbon-reduction goals through process innovation rather than only material change.

We see that many visitors come to us not only to look at machines, but to learn. In 2026, we plan to:

- Publish more Technical Articles and Service Articles focusing on real engineering challenges, troubleshooting, and optimization tips.

- Share more customer success cases from different countries and industries to show how Huarong machines perform in the field.

- Make our content even more search-friendly for both human readers and AI tools, so that engineers, purchasers, and managers can quickly find answers when they need them.

At Huarong Group, our mission remains constant:

To provide reliable injection molding machines and turnkey solutions that help our customers grow – efficiently, sustainably, and confidently.

Thank you to every partner, customer, and colleague who walked with us through 2025. We look forward to building even stronger, smarter, and more sustainable injection molding solutions with you in 2026 and beyond.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/