Latest News

Keep yourself informed about the newest developments and advancements in the injection molding industry.

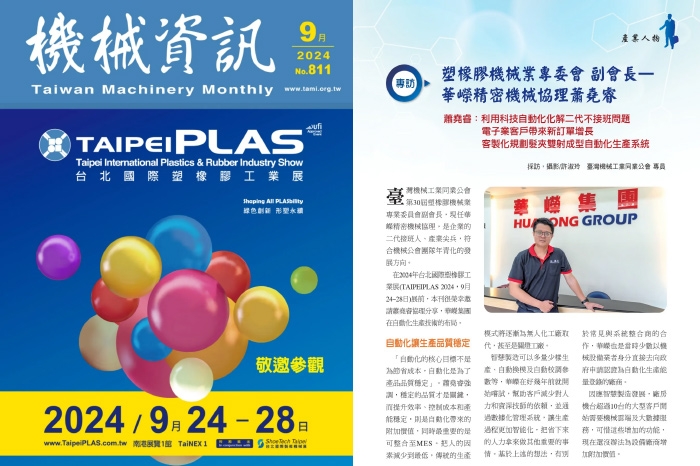

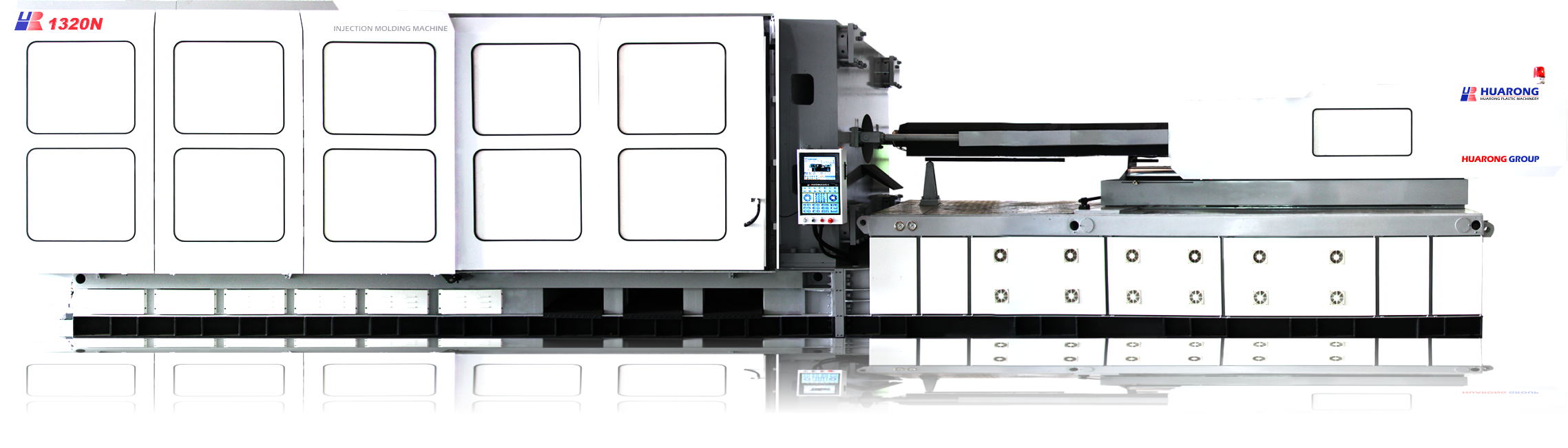

Interview: Vice Chairman of the Plastics and Rubber Machinery Committee – Huarong Plastic Machinery

2024-09-28

Huarong Showcase 4 Innovative Breakthroughs in 7 Injection Molding Machines at TaipeiPlas 2024

2024-09-19

Exhibitions

Join us at upcoming exhibitions and events to witness our injection molding machines in action.

FAQs

Discover answers to frequently asked questions about injection molding technology and machines.

Further reading: Injection Molding Machine Maintenance PDF and Checklist

Further reading: The Science Behind Plastic Caps: How are Plastic Bottle Caps Made

Further reading: What is IML? In Mold Labeling Process, Benefits, and Applications

Further reading: Machinery Installation in Injection Molding: Essential Procedures and Precautions

Further reading: What Is Insert Molding? Process, Advantages and Applications

Further reading: 2 Platen Injection Molding Machine vs 3 Platen

Contact Us

The HUARONG team is ready to assist you with expert knowledge and comprehensive solutions for all your injection molding needs. Whether you need detailed information about our high-quality injection molding machines or guidance on optimizing your production processes, we are here to help.

Contact Us

Contact Us

The HUARONG team is ready to assist you with expert knowledge and comprehensive solutions for all your injection molding needs. Whether you need detailed information about our high-quality injection molding machines or guidance on optimizing your production processes, we are here to help.

Contact Us

Automotive Applications

Automotive Applications  Household Items

Household Items  Building Materials

Building Materials  Food Packaging / Containers (include PET)

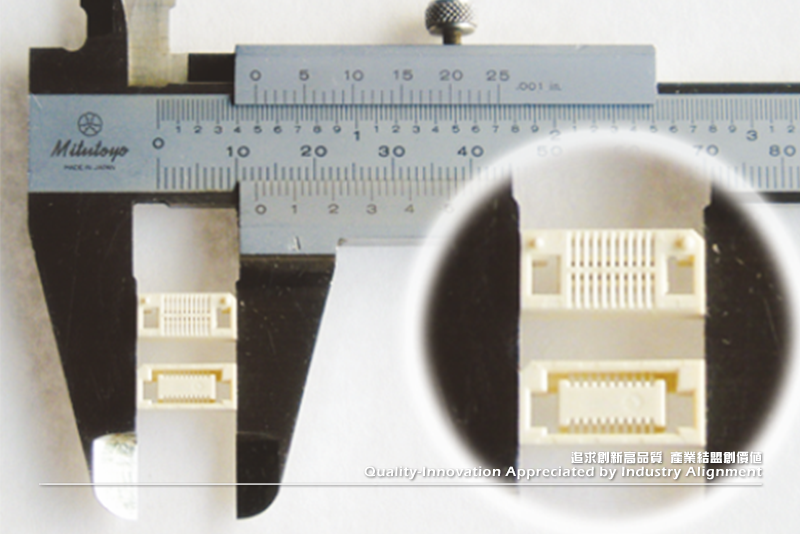

Food Packaging / Containers (include PET)  Electronic Component / Items

Electronic Component / Items  Medical Applications

Medical Applications