The Science Behind Plastic Caps: How are Plastic Bottle Caps Made

2023-05-26 17:38:09

Plastic caps are ubiquitous daily, serving as essential seals for containers like bottles, buckets, and cans. They are typically crafted from various plastics, including polyethylene, polypropylene, and polystyrene, and are manufactured using an injection molding process. These caps are crucial in preserving food freshness, ensuring product quality, and preventing leakage in domestic kitchens or industrial settings.

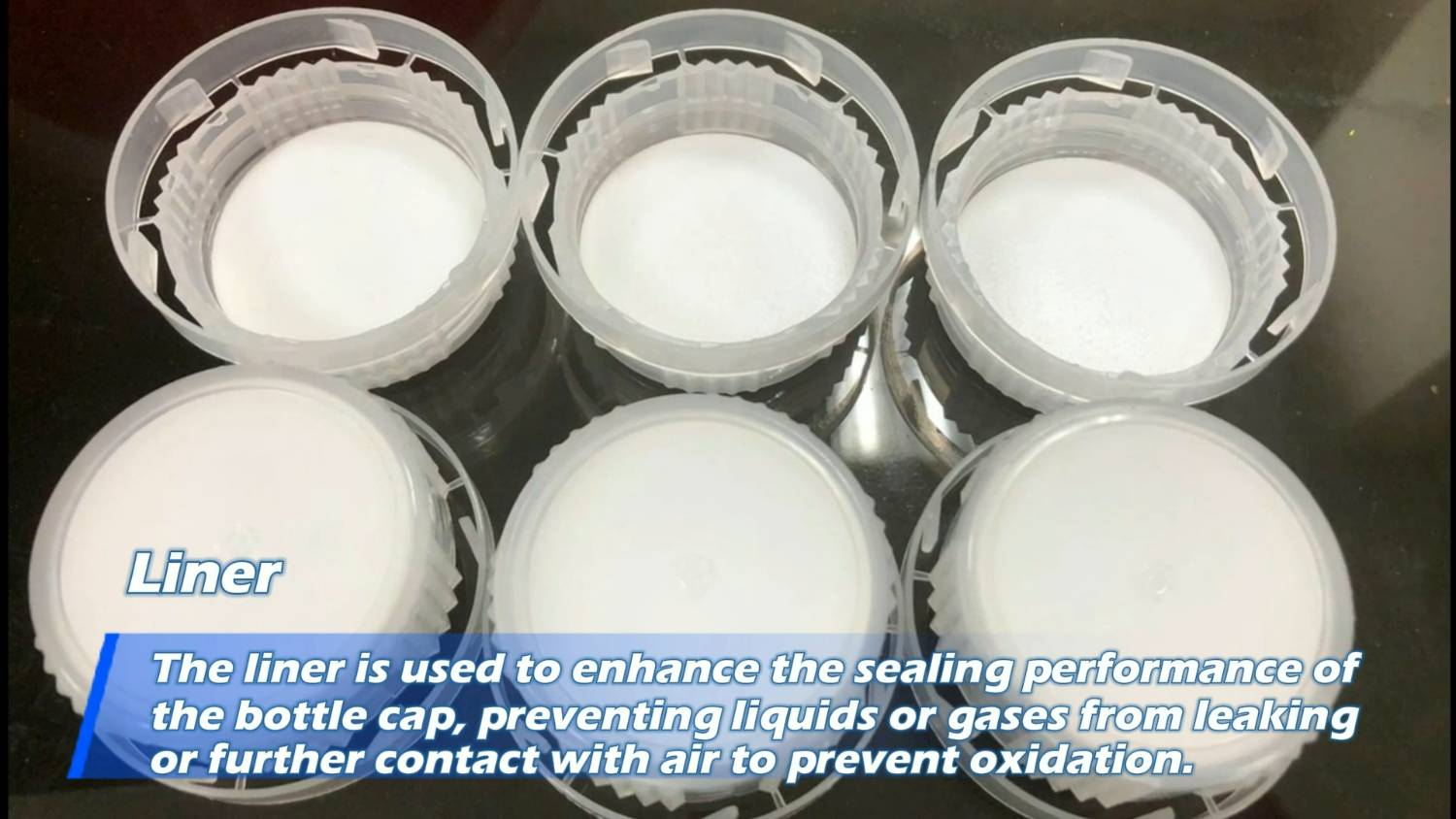

Consider the humble bottle cap. Its primary function is protecting the contents from external contaminants and preventing leaks. The "liner" embedded within the cap is central to this functionality, enhancing its sealing performance. In products with stringent sealing requirements, caps, and liners ensure product quality and safety.

Injection molding machines are the go-to equipment for producing bottle caps. The process involves heating plastic to a molten state and injecting it into a mold through the machine's injection unit. Pressure is applied to maintain the shape, followed by cooling and molding. Once molded, the product is either automatically ejected or extracted using automation equipment, such as robot arms. This process is efficient and rapid, capable of producing large quantities of bottle caps in a short time. A stable injection machine is essential for maintaining high-quality standards.

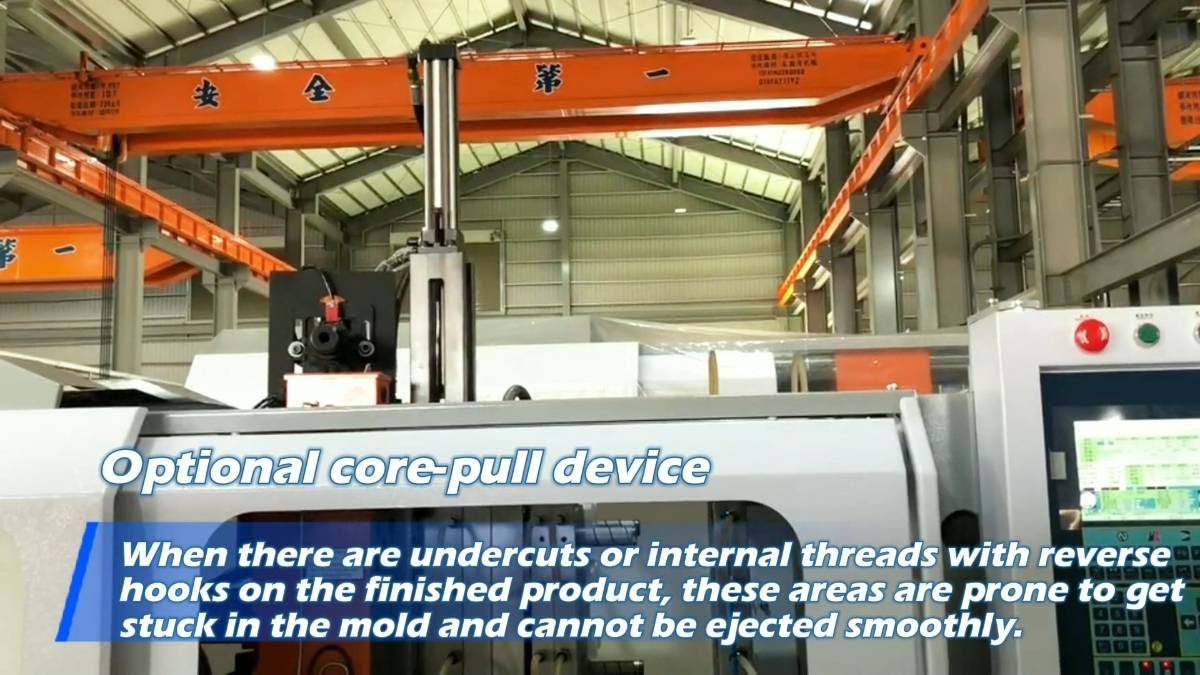

Machine Considerations for Bottle Caps

The interior of a bottle cap often features a reverse hook design for internal threads. An injection molding machine can be equipped with a core-pull device to prevent this part from getting stuck in the mold. This device helps lift the reverse hook before the mold is opened, facilitating easy removal.

Liner Implantation Automation

Combining injection molding machines with automation equipment streamlines liner implantation. After the caps are molded, they undergo liner implantation, a process where automation equipment plays a crucial role. Robot arms, conveyor belts, and monitoring systems ensure accurate liner implantation in each bottle cap.

With extensive injection molding expertise, Huarong offers comprehensive planning and solutions tailored to production needs and product characteristics. From injection machines to molds, peripheral equipment, and automated production, Huarong provides a complete package to meet your needs.

About Huarong's Machines

Huarong recommends using the General injection molding machine - HRN series for bottle cap production. Its inward toggle clamping design enables quick mold opening and closing, reducing cycle times. Additionally, its structurally dynamic computation ensures durability.

- Machine Model: General injection molding machine – HRN series

- Machine Feature:

- Structural parts are analyzed using Nastran In-CAD for safety and reliable operation.

- Box-type platen maximizes clamping durability.

- Original screw design offers wide versatility, high stability, good plastic melting, kneading ability, and improved injection stability.

- Customized service allows adjustments and optional additions based on customer production needs, such as core-pull devices and servo motors.

- Bottle Cap Material: Commonly made from polyethylene or polypropylene.

YouTube of Plastic Caps Production with Liner Automation

Plastic caps are indispensable in packaging, ensuring product safety and freshness. Understanding the science behind their production and the importance of their role sheds light on their significance in everyday life. As technology advances, integrating injection molding machines with automation equipment continues to enhance efficiency and product quality, making plastic caps an integral part of modern packaging solutions.

Your Injection Molding Partner - Huarong

Huarong is a trusted injection molding machine manufacturer, offering stable and durable injection machines. Our professional R&D team can tailor machines to meet specific product requirements. If you're looking for an automation solution, don't hesitate to contact Huarong.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777 #521

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/

Previous news:Huarong Smart Injection Molding Machine: A Stable and Reliable Production Equipment

Next news:The Features and Examples of Vertical Injection Molding Machine with Rotary Table Template