What are 2K Injection Molding and 2K Molding Equipment and Advantages?

2024-03-12 15:38:36

2K injection molding stands out as a popular choice for its ability to combine two or more different materials in the same mold before injection, offering unique advantages and applications. Here, we delve into the world of 2K injection molding, exploring its uses and benefits and showcasing its successful deployment in various industries.

2K injection molding, also known as dual injection molding and two shot injection molding, is a manufacturing process in which two materials are simultaneously injected into the mold cavity. This technique allows for the production of complex plastic parts with varying colors, materials, or properties in a single operation. Typically, the first material is a rigid substance like polypropylene, while the second material is often an elastomeric material such as TPE or TPV. This combination of materials allows for more intricate designs and improved functionality compared to traditional single-material injection molding.

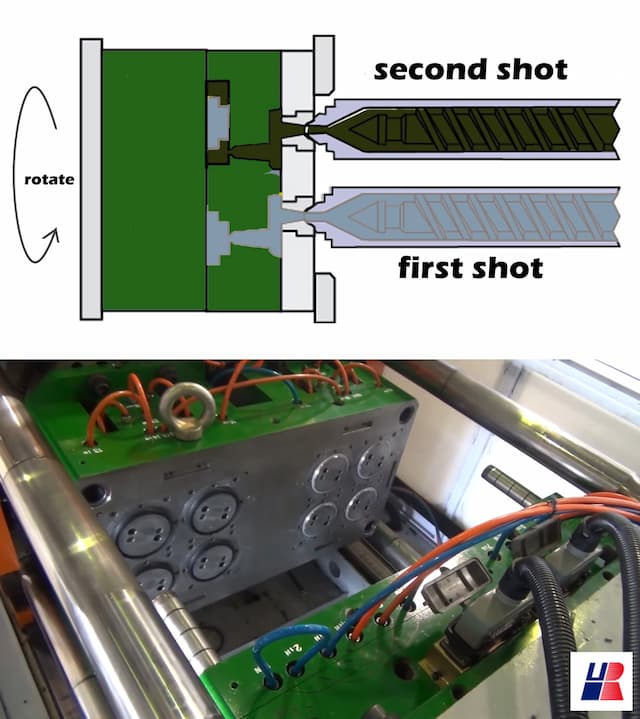

The two shot injection molding process is highly efficient, allowing for the creation of complex, multi-material parts with high precision and tight tolerances. Here's a simplified breakdown of how it works:

- First shot: The process begins with the injection of the first material into a mold cavity to create the initial part structure.

- Mold movement: The mold then rotates or moves to a second station where a second material is injected into a specific area of the first shot.

- Bonding and curing: The two materials bond together, creating a strong, cohesive part with enhanced functionality and aesthetics.

The 2K molding process is ideal for parts with complex geometries, as it allows for precise placement of the second material. Additionally, it reduces production times and costs by eliminating the need for separate molding and assembly operations.

In two shot injection molding, specialized equipment plays a pivotal role in ensuring precise and efficient production processes. The primary components of 2K injection molding equipment include:

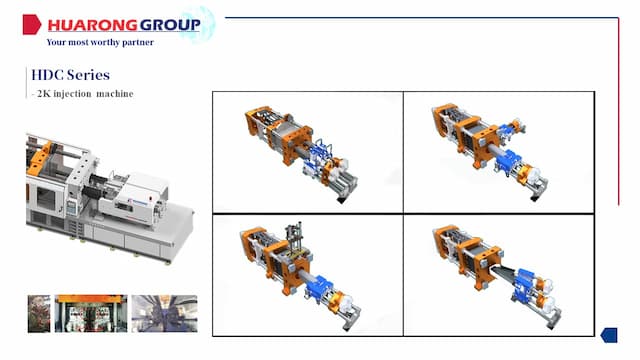

2K injection molding machine

The 2K injection molding machine is the cornerstone of this process. It is programmed to execute two injections in a single cycle. During the first cycle, a nozzle injects plastic into a mold, which is then rotated to allow the injection of a different type of plastic from a second nozzle. This sophisticated machine enables the creation of highly effective end products from disparate polymers.

Related product: 2K injection machine - HDC Series

2K injection mold

The 2K injection mold is another essential component, designed to accommodate the dual-material injection process. This mold features two cavities, each corresponding to one of the materials being used. The design of the mold is crucial in ensuring proper material flow and part formation.

Other supporting equipment

Depending on the specific requirements of the two shot injection molding process, other supporting equipment such as robots for part handling, material mixers for blending the two materials, and quality control systems may also be necessary.

While both overmolding and 2K injection molding allow the combination of multiple materials into a single product, they are different. The key difference between them lies in the process and timing of combining the materials.

Overmolding is often used to add a layer of TPE (thermoplastic elastomer) or rubber over a substrate, which can be a plastic, metal, or brass part and then overmolding it with a second material. This process creates a strong bond between the materials, enhancing the product's functionality and aesthetics.

Compared to overmolding, two shot injection molding injects both plastic materials simultaneously, so it is better at handling more materials and larger production volumes and offers greater utility and efficiency.

There are numerous advantages to using 2K injection molding in manufacturing, including:

- Versatility: Enables the creation of complex, multi-material parts with different colors, textures, and functional features in a single molding cycle.

- Improved quality: Clear plastics, colored graphics, and neat finishes achieved through 2K molding enhance product durability and aesthetic appeal.

- Increased product value: The multi-material efficiency of 2K molding enhances the utilitarian aspect of products, increasing their overall marketplace value.

- Expense and time efficiency: Streamlined manufacturing processes in 2K molding reduce the price per unit and cycle time, leading to greater efficiency and cost-effectiveness.

- Reduced handling and secondary assembly: 2K molding minimizes the need for priming, painting, or coating products post-molding, reducing overall assembly time and costs.

2K injection molding finds widespread applications across various industries, including automotive, electronics, medical devices, and consumer goods. Some common applications include:

- Automotive industry: Used for producing interior and exterior components with soft-touch surfaces, such as instrument panels, door handles, and trim pieces.

Related case video: Double injection machine production - Electronics industry: Ideal for manufacturing electronic enclosures and connectors with integrated seals and gaskets for improved performance and durability.

Related case study: How the Production of Headphone Outer Cases Works? - Dual Injection Molding Machine - Medical devices: Enables the production of medical components with biocompatible materials and overmolded grips for enhanced ergonomics and functionality.

- Consumer goods: Used to create aesthetically appealing products with soft-touch finishes, such as personal care items, household appliances, and sporting goods.

Related case study: Dual Color Hair Clip Machine - How To Make Your Own Dual Color Hair Clips - Household appliances: Used for components that require a combination of rigid and soft-touch materials.

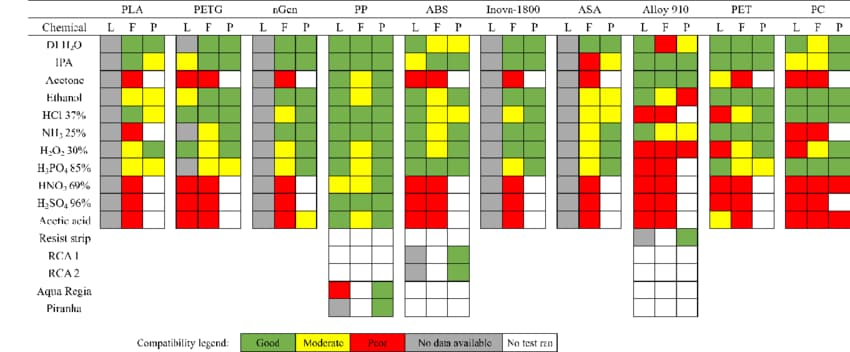

Selecting the appropriate materials is crucial for achieving optimal results in 2K injection molding. While this process offers significant design freedom, it's essential to consider fundamental factors to ensure compatibility and performance.

- Material combinations: Carefully choose materials that are compatible both physically and chemically. Some combinations may work better together, leading to improved product quality.

- Proper bonding: Materials used in two shot injection molding should have similar melt temperatures to ensure proper bonding between layers. This is crucial for the structural integrity of the final product.

- Intended use: Material selection should be based on the final product's intended use and performance requirements. Factors such as durability, flexibility, and chemical resistance should be considered.

- Harder materials First: In most cases, harder materials are injected first, followed by softer materials. This sequential injection helps achieve the desired mechanical properties and surface finish.

What is 3K injection molding?

3K injection molding, or three-shot molding, is an advanced manufacturing process that involves injecting three different materials or colors into a single mold to create a complex, multi-material product. This technique allows for the combination of materials with varying properties, such as hardness, flexibility, and color, in a single production cycle.

What is 1K injection molding?

1K injection molding, or single-shot molding, is a conventional molding process that involves injecting a single material into a mold cavity to produce a plastic product. Unlike multi-shot molding processes such as 2K and 3K injection molding, 1K injection molding uses a single injection unit to inject the material into the mold.

2K injection molding is a highly versatile and efficient manufacturing process that offers numerous benefits for producing complex, multi-material parts with high precision and tight tolerances. By understanding the process, requirements, and design guidelines, manufacturers can leverage the advantages of two shot injection molding to create high-quality products for various industries, including medical, automotive, consumer electronics, and more. When choosing a 2K injection molding machine service provider, it's essential to consider factors such as certification, experience, and service offerings to ensure a successful and cost-effective manufacturing process. Huarong Group is an experienced injection molding machine manufacturer; if there is a need for 2K injection machines or automation, please feel free to contact Huarong.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777 #521

- Address: No.21-6, Zhongzhou,Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/

Previous news : What is IML?4 Benefits of In Mold Labeling

Next news : Vertical Injection Molding vs Horizontal Injection Molding for Plastic Components