How to Manufacture High-Quality Dental Flossers and Interdental Brushes

2022-12-27 16:53:52

Maintaining optimal oral hygiene is crucial for preventing cavities and gum disease. The American Dental Association (ADA) recommends cleaning your teeth daily with an interdental cleaner, such as floss, to achieve this goal. As such, the production of dental flossers and interdental brushes plays a vital role in oral health. In this article, we explore the process of manufacturing these essential oral care tools, focusing on the advanced solutions offered by Huarong, an experienced injection molding machine manufacturer.

Modern production methods emphasize automation and robotics to streamline processes and ensure consistent, high-quality output. For complex items like dental flossers and interdental brushes, automation is essential. Automated systems reduce production time and costs while meeting stringent quality standards.

Huarong specializes in providing turnkey solutions for dental flossers and interdental brush production. Their offerings include vertical injection molding machines, injection molds, and automation solutions tailored to meet the specific needs of customers in the injection molding industry.

How to produce high-quality dental Flossers and interdental brushes?

Dental Flosser Production

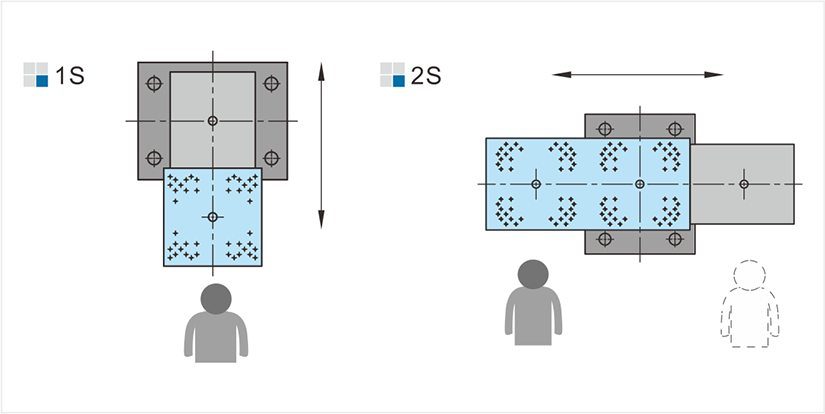

Huarong's YH series machines are designed for producing dental flossers. These machines feature a vertical clamping unit with a rectangular operating platform between tie bars, making it easy to insert materials. The twin injection cylinder ensures smooth and powerful injection, while the sliding table design allows for easy loading and unloading of molds, increasing productivity.

Related product: Sliding table vertical clamping vertical injection machine – YH series

Interdental Brush Production

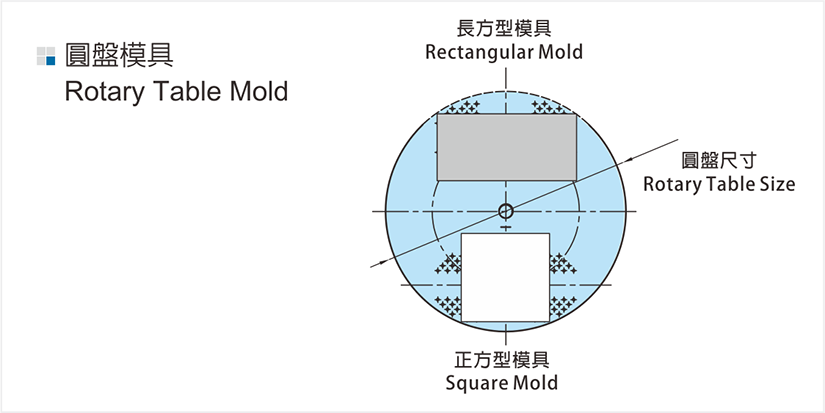

Huarong's YR series machines are ideal for manufacturing interdental brushes. These machines feature a vertical clamping unit with a rotary table that oscillates 180°, making it easy to load materials and pick out finished parts. The twin injection cylinder ensures smooth injection, while the rotary table design enables advanced efficiency with its 2-station function, capable of expanding to 3 or 4 stations with automation linkup.

Related product: Rotary table vertical clamping vertical injection machine - YR series

For a visual demonstration of the production process, refer to the video below, which showcases Huarong's vertical injection molding machines in action:

- Machine Models: YH series (for dental flossers) and YR series (for interdental brushes)

- Plastic Material: PP+TPE

- Mold Cavities: 1. 12 cavities (for dental flossers) 2. 16 cavities (for interdental brushes)

▶️YouTube:

High-quality dental flossers and interdental brushes require advanced technology and automation. Huarong's vertical injection molding machines offer a reliable solution for manufacturers looking to efficiently and effectively produce these essential oral care tools. As an experienced injection molding machine manufacturer, if you have any inquiry related to injection molding business, please feel free to contact Huarong.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777 #521

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/

Previous news: Injection Molding Machine - Wide Range of Products Produced By It

Next news:Two-Platen Injection Molding Machine Obtained Patent Certification to Provide Better Machine