Unlocking the Potential of Injection Molding Machines - Plastic Flower Pot Production

2022-12-13 10:54:43

In the realm of plastic production, injection molding machines reign supreme, capable of churning out a vast array of products with precision and efficiency. From everyday items like buttons and caps to larger components such as flowerpots and car bumpers, these machines offer unparalleled versatility and reliability. One company that stands out in this field is Huarong, renowned for its innovative solutions and commitment to customer satisfaction.

Plastic flower pots have become indispensable garden accessories, favored for their durability and aesthetic appeal. With the help of injection molding machines, these pots can be produced in a myriad of shapes, sizes, and colors, catering to gardeners' diverse needs. Unlike their traditional counterparts, plastic flower pots are resistant to sun exposure and rain erosion, making them ideal for outdoor use.

Benefits of Plastic Flower Pots

According to Plantlogic, a leading gardening resource, plastic flower pots offer several advantages over other materials. First, they provide greater control over plant growth, resulting in better yields. Additionally, their flexible design encourages innovation, allowing for the creation of unique garden arrangements. Furthermore, plastic pots are easy to maintain and come in a wide variety of designs, making them a smart investment for any gardener.

- Distinctive Branding: Create a memorable brand identity that resonates with your target market.

- Eco-Friendly Packaging: Emphasize recyclability and environmental responsibility in your packaging.

Versatility of Plastic Flower Pots

Unlike traditional clay pots, plastic pots can be easily molded into various shapes, sizes, and colors, allowing for a wide range of creative designs. With different plastic injection molding materials, color masterbatch, and mold, the injection molding machine produces various plastic flower pots. This versatility extends beyond aesthetics; plastic pots are also lightweight, making them easy to move around and rearrange in gardens or indoor spaces. Additionally, plastic pots can withstand various weather conditions, making them suitable for both indoor and outdoor use. Whether you're looking for a sleek, modern design or a rustic, traditional look, plastic flower pots can cater to diverse styles and preferences, making them a versatile choice for any

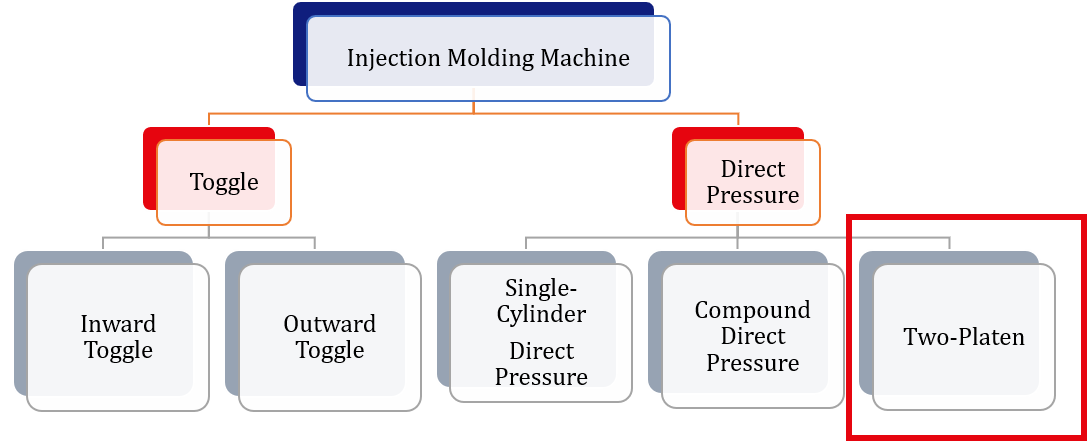

For the production of medium to large-sized products, the two-platen injection molding machine is a popular choice. Its unique design features a shorter machine length and a longer mold opening stroke, making it ideal for accommodating larger molds. Unlike traditional machines, the two-platen design eliminates the problem of toggle wear, ensuring precision and reliability over time. Additionally, its simple mold thickness adjustment and quick mold change capabilities make it a versatile and efficient choice for manufacturers.

Two Platen Injection Molding Machine

Huarong's two-platen machine, the NRH series, is engineered to perfection, offering a host of features that set them apart from the competition. With a 35% improvement in machine materials, these machines are not only durable but also easy to maintain. The optimized four direct-pressure hydraulic cylinders ensure a balanced tensile force, while the patented sliding module with an inner limit design ensures high loading capacity and easy maintenance. Furthermore, Huarong's intelligent management system, HFM, provides real-time monitoring and alerts, allowing for quick and accurate decision-making.

Machine Feature

- Superb Medium/Large injection molding machine Improving 35% of machine materials, making maintenance simple, effectively save production space without limitation.

- Optimized 4 direct-pressure hydraulic cylinders Balance equivalent tensile force.

- Supporting sliding module with an inner limit design (Patented M578643) High loading and two-way guiding function, which is easy to maintain, taking into account safety and convenience.

- Option of intelligent management Abnormal alarms can be notified by LINE or Telegram to control production situation.

Related product: Two-platen machine - NRH series

Add Functionality of Smart Management System

- Master whole plant status and assist in quick and accurate decision-making

- From passive maintenance to active maintenance, the system will automatically check the comparison value after production, and users can also set the deviation range according to different products

- When the machine detects any slight abnormalities in the data, it will actively report via Line/Telegram timely notification to reduce the occurrence of problems.

Related product: Huarong factory management platform - HFM

▶️YouTube:

- Plastic products: Plastic flower pots, Potted plants,

- Raw material: PP

- Mold cavity: 1

Injection molding machines are vital in producing various plastic products, including plastic flower pots. For medium to large-sized products, the two-platen injection molding machine is ideal. It features a shorter machine length and a longer mold opening stroke due to its two-platen structure. Unlike machines with toggles, the two-platen machine has no relative movement, thus avoiding toggle wear issues. This design maintains mold closing precision for longer periods and reduces maintenance costs. These advantages are more pronounced as the injection machine size increases. Additionally, the two-platen machine offers simple mold thickness adjustment and quick mold changes.

Companies like Huarong lead the industry with innovative solutions and cutting-edge technology. By utilizing these machines' versatility and efficiency, manufacturers can meet diverse consumer needs while ensuring high standards of quality and reliability. As an excellent injection molding machine manufacturer, please feel free to contact Huarong for the machine inquiry.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777 #521

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/

Previous news:Dual Color Hair Clip Machine - How To Make Your Own Dual Color Hair Clips

Next news:How to Produce a High Quality Dental Flosser / Interdental Brush