Injection Molding Machine Solutions for Precision Plastics

HUARONG GROUP provides a comprehensive range of Injection Molding Machines for industrial plastic manufacturing. Our Injection Molding Machine product line covers clamping forces from 60 to 4,000 tons and supports single-shot and multi-shot processes with horizontal and vertical machine configurations.

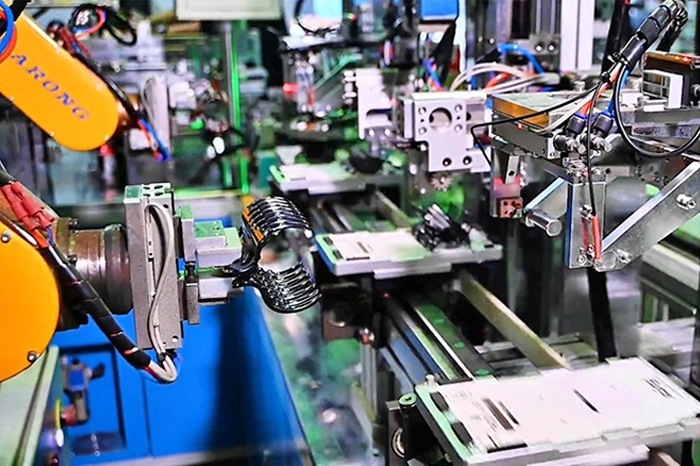

Each Injection Molding Machine is designed to support stable production, controlled injection performance, and compatibility with automation systems for applications such as automotive parts, packaging products, consumer goods, and technical plastic components.

As a Taiwan-based Injection Molding Machine manufacturer, HUARONG GROUP integrates manufacturing experience and application engineering to support customers in machine selection, mold matching, and production planning.

- Machine Configuration Options: Single-shot or multi-shot Injection Molding Machines with horizontal and vertical clamping structures.

- Clamping Force Range: Injection Molding Machines available from 60 to 4,000 tons for different mold sizes and product requirements.

- Process Compatibility: Supports general plastic molding processes and integration with automation equipment.

- Application Coverage: Suitable for automotive components, packaging, consumer products, and industrial plastic parts.

Single Injection Machine

- For production needs that involve single plastic products, our single-shot injection molding machines are ideal choices. These machines are known for their precision, efficiency, and reliability in producing consistent, high-quality parts. Depending on your specific production requirements, you can choose either toggle-type machines for rapid cycles or two-platen injection molding machines for handling larger molds with ease.

- Precision: Ensure consistent quality with each cycle.

- Versatility: Choose between toggle-type and two-platen designs.

- Efficiency: Optimize production processes with advanced technology.

-

Machine models

Multi Injection Machine

- When your production requires two or more types of plastics or colors, our multi-shot injection molding machines offer the perfect solution. These machines can inject multiple materials simultaneously, improving production efficiency and reducing cycle times. Customization options allow for precise control over injection and clamping units, enabling seamless integration with your existing molds and production workflows.

- Efficiency: Inject multiple materials or colors at the same time, improving production efficiency and reducing cycle times.

- Customization: Tailor the injection and clamping units to meet your specific production needs and mold designs, ensuring precision and flexibility.

-

Machine models

Special Injection Machine

- Addressing specific plastic and product requirements, Huarong focuses on machines designed for specific plastics or unique product designs.

- Tailored Design: Machines are specially designed to meet unique plastic and product requirements, ensuring optimal performance and efficiency.

- Enhanced Capabilities: Address complex molding challenges with specialized machines that handle everything from in-mold labeling to high-speed injection.

-

Machine models

Sucessful Case Study

This case study analyzes the challenges of mass production of plastic eyeglass frames, illustrating how a division of labor between servo injection molding and vertical sliding mold injection molding machines can help customers improve dimensional consistency, appearance quality, and overall production line efficiency.

In the competitive world of manufacturing, efficiency and quality are paramount. For hair clip manufacturers, finding the right production solution can be challenging. However, one of Huarong company's success stories stands out—a testament to the transformative power of modern technology in manufacturing.

FAQ

Further reading: Learning Injection Molding Machine Components, Parts and Functions

Further reading: Choosing the Right Injection Molding Machine: A Comprehensive Guide

Further reading: 2 Platen Injection Molding Machine vs 3 Platen

Injection Machine Inquiry

Professional Staff at Your Service, Your Partner in Plastic Processing.