Hair Clip Making Machine: A Success Story in Injection Molding Automation

2024-03-06 10:40:22

In the competitive world of manufacturing, efficiency and quality are paramount. For hair clip manufacturers, finding the right production solution can be challenging. However, one of Huarong company's success stories stands out—a testament to the transformative power of modern technology in manufacturing.

Transitioning from traditional manufacturing to automation can be daunting, but with the right equipment and expertise, it becomes a smooth journey.

“My journey with injection molding began when I decided to invest in a high-quality hair clip making machine. After thorough research, I chose the Huarong Plastic Machinery from Taiwan. The decision was based on their reputation for excellence and reliability in the injection molding machine manufacturer." the customer remarked.

Challenges of traditional manufacturing

Before the advent of automation, traditional hair clip manufacturing methods were labor-intensive and time-consuming. Hair clip making machines operate through an injection molding process to shape the plastic material into the desired hair clip design, cut cold runners and apply any necessary finishing touches, such as polishing or painting.

After the injection molding machine produces each hair clip, workers manually install two pieces with a pin. The finished hair clips are then ready for packaging and distribution. However, this manual labor not only increased production time but also led to a high risk of human error, resulting in defective products and increased material wastage.

Further reading related to injection molding process: Injection Molding Process, Applications, and Machinery - A Complete Guide

Benefits of automation

Recognizing the limitations of traditional manufacturing, the customer sought a more efficient solution. Automation emerged as the answer, promising increased productivity, consistent quality, and cost savings.

“Our experience with the Huarong Plastic Machinery injection molding machine has been nothing short of exceptional.” the customer remarked.

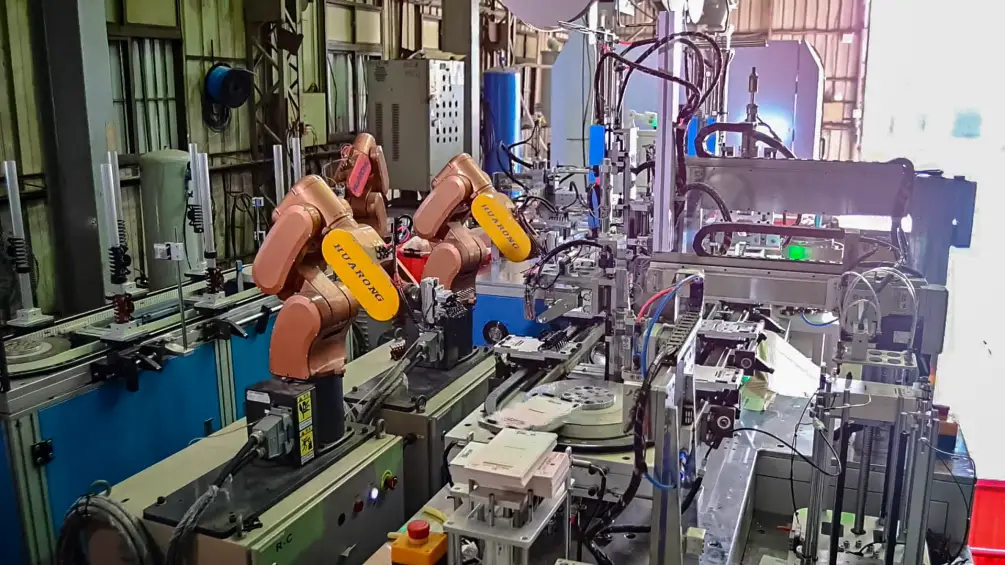

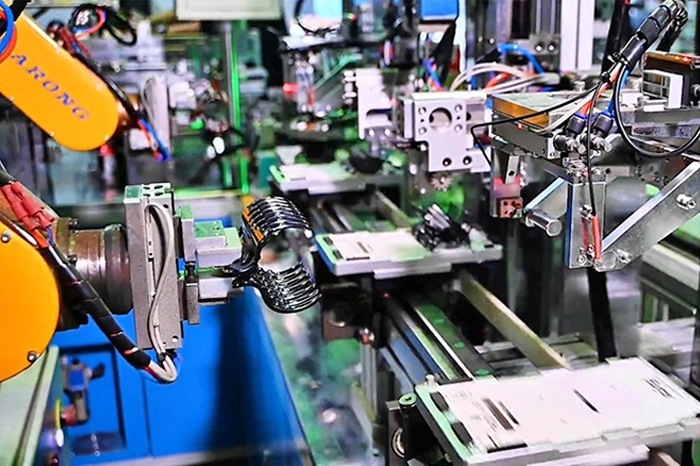

Huarong understands customers' needs, so it communicates with them long-term to split the production process. It uses a combination of robotic arms, conveyor belts, and other automated equipment to produce hair clips with the injection molding machine to offer more precision and efficiency total solution.

Automation revolutionized the hair clip manufacturing industry by streamlining production processes and reducing reliance on manual labor. To allowed customer to meet the growing demand for our hair clips without compromising on quality.

Hair clip making machine automation video:Automation Automated Hair Clip Production With Injection Molding

What plastic materials are used to make hair clips?

Polypropylene (PP), polyethylene (PE), polystyrene (PS), and others are common plastic materials used in the manufacture of hair clips. For a shiny and non-slip surface, PMMA and TPU materials can be used in dual injection molding for production.

Further reading: Dual Color Hair Clip Machine - How To Make Your Own Dual Color Hair Clips

Are hair clip making machines easy to maintain?

Yes, Huarong injection machine's advanced features and user-friendly interface made it easy for our team to operate and maintain.

Can hair clip making machines be used to produce other types of plastic accessories?

Yes, by changing the design of the injection mold (mold core replacement) or replacing different molds, it is possible to use the same machine to produce multiple products.

The transition from traditional manufacturing to automation marked a significant milestone in the hair clip manufacturing industry. Huarong Group is an experienced injection molding machine manufacturer to offer high-quality machines at a competitive price. Our core focus is on addressing the production needs of injection molding factories, aiming to progress together as the best partners in the international market. If there are needs for injection machines or automation, please feel free to contact Huarong.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777 #521

- Address: No.21-6, Zhongzhou,Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/

Previous news : Injection Molding Machine HS Code: Everything You Need to Know