What's the reason for Indian auto parts manufacturer to choose Huarong's injection molding machines?

2022-06-15 10:58:26

Expected to be the third largest auto market in the world by 2026? India's auto industry is set for growth

According to Invest India, India is expected to become the third largest auto market in the world by 2026.

In terms of overall auto industry trends, driven by electric vehicles and the IoT, the automotive industry continues to attract investors' attention. Although the shortage of semiconductors has plagued the Indian auto industry, the shortage and demand are stimulating investment by auto chip makers. The trend of cross-border investment and market growth in the Indian automotive industry has attracted investors' attention and led to the belief that there will be more supply in India in the coming years.

Industrial alliances create value, the benchmark for Indian auto parts manufacture

When the Indian auto industry was gradually taking shape in the 1980s and 1990s, Huarong's Indian customer saw this great opportunity and joined the automotive lighting and auto-related parts manufacturing industry. Now it has been established for more than 70 years. It has become a local indicator company in India, a leading manufacturer and supplier of auto parts and systems.

Horizontal, vertical injection molding machine, for all your injection needs

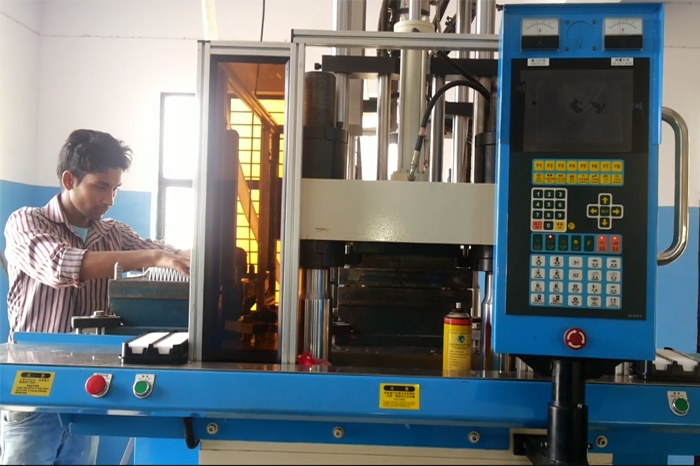

When the customer decided to join the automobile manufacturing industry, our sales noticed the production demand of BMC products in the customer's factory during the visit. Huarong, as one of the few manufacturers in Taiwan with the most complete injection molding machine models, after understanding the customer's production situation, we recommended to use our Bulk Molding Compound injection molding machine HMC to produce BMC products, which not only stabilizes but also increases production. After negotiation, the customer who was persuaded by the sincerity of our service, finally decided to choose our machine. Now there are dozens of HMC series machines in the customer's factory because of the unique features of HMC and Huarong's sincere service spirit.

HMC - Bulk Molding Compound injection molding machine

Huarong HMC series, tailor-made machine design for the production of BMC materials:

- Auto feeding mechanism : Speedy feeding for efficient molding.

- Isolation boards : Minimizing heat transfer to platens.

- Accumulator assisted (optional) : Accumulator-assisted injection for shining effect and rapid forming.

- Feeding platform for convenience. : To ensure feeding safety.

- Dedicated wearing-proof and corrosion-resisted injection screw : Superior durability.

- Individualized separate control on tool heating : To ensure the average quality of the finished product during injection molding.

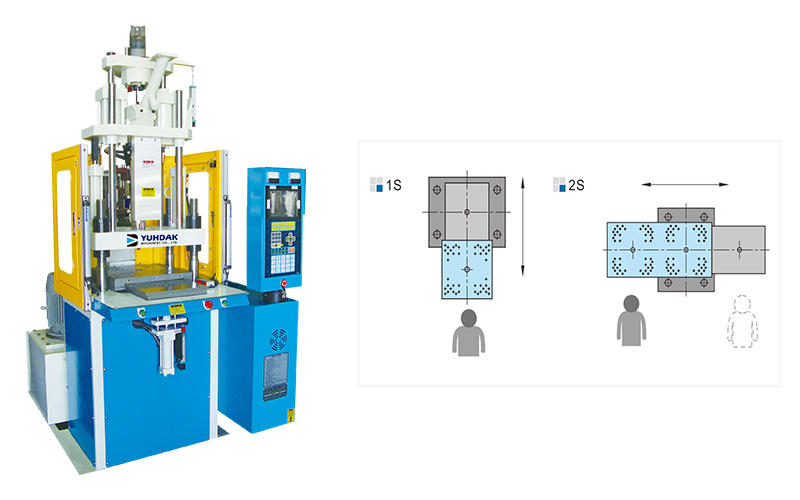

Have production needs for inserts? Choose vertical injection molding machine

An opportunity made customers notice that Huarong not only involved in horizontal injection machines, but also provided a complete range of vertical injection machines. At that time, the customer wanted to expand the product line of automotive filters. This kind of product needs to embedded the filter before injection molding. After the customer noticed that Huarong can also provide vertical injection machines, Huarong helped the customer to understand the mold and embedding methods with the rich experience as the injection molding machine manufacturer , and then open the long-term cooperation between the two parties.

Vertical injection molding machine with double sliding, reduce time waste and improve production efficiency

Considering the embedded condition of the car filter and the cycle time, we recommended customer purchase the YH series, Vertical Clamping Vertical Injection, and can be equipped with a single sliding or double sliding working platform according to the needs of production.

- Single sliding pushes the lower mold out for easy loading/unloading.

- Double sliding use two lower mold, machine molding the parts while the operator is loading the other mold, to increase productivity.

The YH series not only can be customized, but also is easy to operate and durable:

- Four-column/vertical clamping, vertical injection. Rectangular shape between tie bars for easy insert.

- Double injection cylinder balanced for smooth and powerful injection.

- Simple structure, small occupancy.

- Double action clamping cylinder for fast clamping, slow speed high pressure clamping.

The key to customer trust - the most complete models and durable and reliable quality

Huarong's consistent core value is " Quality-Innovation & Industry-Alliance ". In order to meet all the injection molding needs of customers, Huarong continues to expand its product line in horizontal research and development. Therefore, Huarong is one of the few injection machine manufacturers in Taiwan with the most complete range of injection molding machines, not only providing horizontal, vertical and multi-shot injection machines, but also establishes an automation and intelligence department under the wave of Industry 4.0 to assist customers in planning fully automated production and Build a smart factory.

Huarong continuously optimizes the sturdiness and durability of injection molding machines in vertical research and development. The customer has purchased HMC and YH series injection molding machines for nearly ten years, and said that they are very confident to cooperate with us, even in the case of local anti-dumping, they are still willing to purchased our machine because the abnormal rate of the machine has been low over the years. For Indian customers, they attach great importance to the cost and production efficiency of the machine. Therefore, during the cooperation process, Huarong brought more than expected value to customers through the durability of the machine and reliable after-sales service.

Huarong is the first injection molding machine manufacturer to register a company in India. It trains local engineers to assist Indian customers to troubleshoot problems, and provides instant after-sales service with zero time difference. There are offices in Delhi, Ahmedabad, Pune, Bangalore and Chennai. Sturdy, durable and reliable are the core of Huarong's injection molding machine, and reliability is the key to making customers trust us. When conducting business development, other agents can only provide standard machine specifications, while Huarong provides machines that make money for customers. Huarong can not only communicate with customers flexibly, but also provide customers with customized machines.

Trust comes from sincere communication. Huarong has always insisted on being the most worthy partner of customers, being customer-oriented and meeting the needs of injection molding. Therefore, it is a reliable good partner for industry alliances that customers are willing to entrust and invest.

Previous news : The Role of Injection Machines in Electrical Instruments Equipment Production: A Success Story

Next news : Maximizing Injection Molding Machine Efficiency Through Preventive Maintenance