What Is Overmolding? Process, Applications, and Key Differences from Insert Molding

2024-05-07 16:25:00

Overmolding is a versatile injection molding technique used to combine multiple materials into a single, functional part. Unlike single-material molding, overmolding enhances product performance, aesthetics, and ergonomics. This article explores the overmolding process, its applications across industries, commonly used materials, advantages, and the key differences between overmolding and insert molding.

Overmolding is a multi-material injection molding process where a substrate (base material) is overlaid with a secondary material. The substrate can be metal, plastic, or other materials, while the overmolded layer provides specific properties, such as soft grips, waterproofing, or vibration dampening. Overmolding is widely used in industries requiring rapid prototyping and custom parts manufacturing, combining materials like plastic, rubber, and metal for enhanced functionality.

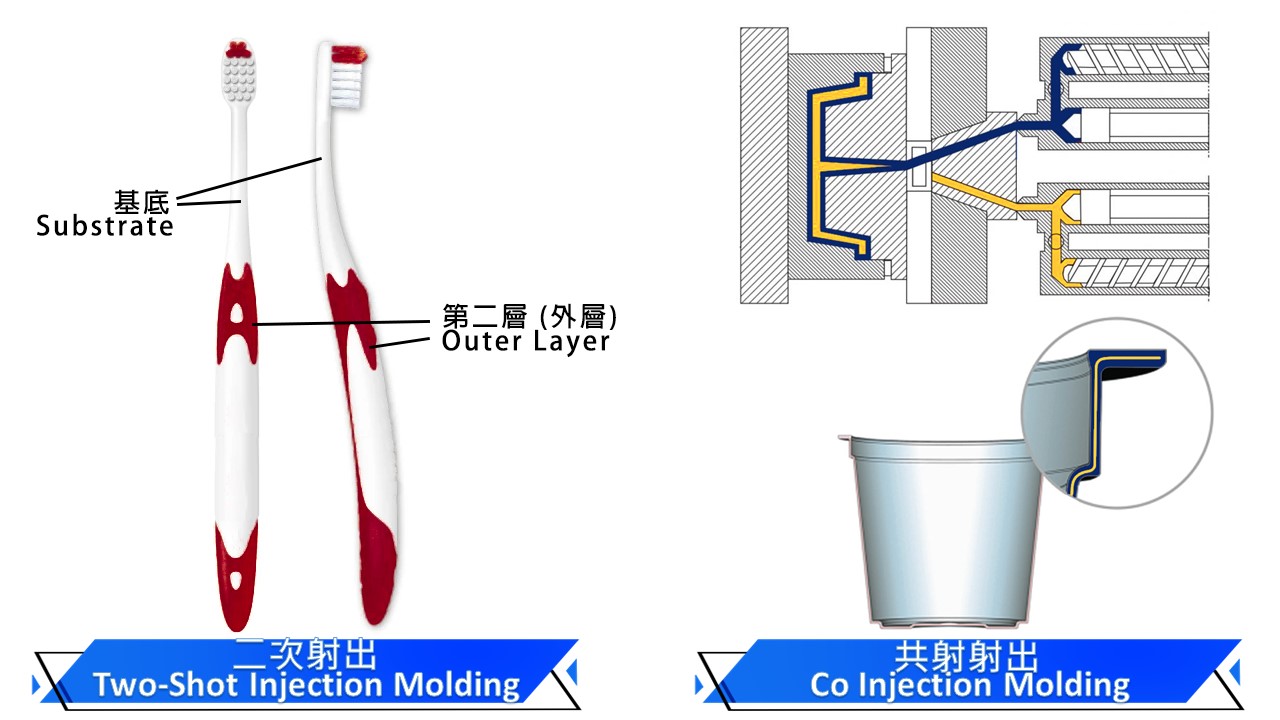

Depending on the complexity of the product and material combinations, overmolding can be performed using various methods. The two most common techniques are Two-Shot Injection Molding and Co-Injection Molding. Both processes enable manufacturers to create multi-material components efficiently and enhance product performance.

Two-Shot Injection Molding

Two-shot molding involves injecting two different materials sequentially within the same mold. It’s ideal for creating parts with:

- Soft-touch grips

- Integrated seals

- Multi-color or multi-material designs

Related product: Vertical Clamping Vertical Injection Machine – YH Series

Co Injection Molding

Co-injection molding, also called sandwich molding, simultaneously injects two materials to create a multi-layered part. It improves:

- Durability through core and skin material combinations

- Aesthetic appeal with multiple textures or finishes

- Cost-efficiency by using economical core materials

Related product: Dual Injection Machine – HDC Series

The success of overmolding depends on selecting the appropriate materials. Common injection molding materials include:

- Thermoplastics: Polyethylene (PE), Polypropylene (PP)

- Elastomers: Thermoplastic Elastomers (TPE)

Factors to Consider in Material Selection

- Temperature resistance

- Bonding capabilities

- Hardness and flexibility

- Vibration dampening

- Chemical and weather resistance

Selecting the right materials ensures your overmolded product achieves the desired functionality and durability.

Overmolding is a groundbreaking process that delivers exceptional value by enhancing product functionality, durability, and design. By integrating multiple materials seamlessly, manufacturers achieve results that surpass traditional single-material injection molding methods. Below are the comprehensive advantages of overmolding:

Enhanced Functionality

Overmolding combines materials with contrasting properties to unlock advanced functionalities. For instance:

- A rigid plastic substrate provides structural strength, while a soft elastomer layer improves grip and comfort.

- Insulation layers can add thermal or electrical protection for products in electronic or automotive applications.

This versatility allows overmolding to improve usability, making it an ideal choice for consumer goods, medical devices, and industrial tools.

Improved Durability and Strength

Overmolding enhances the strength and lifespan of components by creating a strong bond between materials. Key benefits include:

- Impact resistance: Helps products endure drops, shocks, and repeated use.

- Environmental resilience: Protects against harsh conditions like extreme temperatures, moisture, and UV exposure.

This is particularly advantageous for automotive components, power tools, and outdoor equipment that experience high stress or wear.

Cost-Effective Manufacturing

While initial tooling costs may be higher, overmolding significantly reduces long-term production costs by:

- Eliminating secondary processes: No need for gluing, painting, or assembling separate components.

- Streamlining production: Reduces assembly time by molding multi-material components in a single step.

- Material optimization: Overmolding allows the use of economical core materials for strength while applying premium materials for functionality and aesthetics.

These efficiencies make overmolding an excellent choice for high-volume production in industries such as electronics and medical devices.

Aesthetic Appeal and Design Flexibility

Overmolding empowers manufacturers to produce visually appealing products with superior design flexibility. Key features include:

- Multi-color designs: Enhance branding by combining contrasting or complementary colors.

- Textured finishes: Achieve soft-touch surfaces, matte, or glossy finishes to improve product appearance.

- Customization: Allows the creation of complex shapes and intricate details without compromising aesthetics or functionality.

This makes overmolding ideal for consumer-facing products like household goods, wearable devices, and automotive interiors.

Ergonomic and Functional Designs

Overmolding improves product usability by integrating ergonomic features that enhance user comfort and safety. Examples include:

- Soft-touch grips: Common in tools, medical devices, and handheld electronics to reduce hand fatigue.

- Non-slip surfaces: Improves grip and control in wet or high-pressure environments.

- Reduced user fatigue: Overmolded components are lightweight yet strong, contributing to better ergonomics.

These functional improvements are invaluable in medical tools, industrial equipment, and personal care products.

Vibration Damping and Noise Reduction

By using materials like TPE (Thermoplastic Elastomers) or soft plastics, overmolding minimizes vibrations and noise levels during product operation. This is especially beneficial for:

- Power tools: Reduces operator fatigue caused by prolonged use.

- Electronics: Dampens noise and prevents damage caused by vibrations.

- Appliances: Enhances user experience by lowering operational noise.

Weather and Chemical Resistance

Overmolding protects products by creating weatherproof and chemically resistant barriers. This ensures:

- Protection against moisture: Prevents corrosion and water ingress in outdoor or marine applications.

- Chemical durability: Protects products exposed to oils, solvents, and other harsh chemicals.

These properties make overmolding indispensable for automotive parts, industrial machinery, and outdoor tools.

Simplified Assembly

Overmolding reduces the need for additional components by combining multiple parts into a single, unified product. Benefits include:

- Fewer assembly steps: Reduces labor time and manufacturing costs.

- Higher product integrity: Fewer joints and connections result in stronger, more reliable components.

This makes overmolding particularly effective for complex designs and high-precision components.

Overmolding is widely applied across industries to enhance product design, comfort, and durability:

- Consumer Electronics: Soft-touch grips on devices

- Medical Devices: Surgical instruments with enhanced ergonomics

- Automotive: Control knobs with improved tactile feedback

- Industrial Tools: Handles designed for comfort and usability

- Household Goods: Toothbrushes and kitchen tools with soft-touch handles

Overmolding addresses unique manufacturing challenges by providing tailored solutions for durability and functionality.

While both overmolding and insert molding combine multiple materials, their applications differ:

When to Use Overmolding

- Ergonomic Features: Soft grips or tactile surfaces

- Multi-Material Designs: Aesthetic and functional enhancements

- Environmental Protection: Vibration dampening and weather resistance

When to Use Insert Molding

- Mechanical Strength: Combining metal inserts with plastic for structural integrity

- Complex Geometries: Threaded fasteners and intricate connectors

- Cost-Effective Integration: Reducing assembly steps by combining components

Further reading: What Is Insert Molding? Process, Advantages and Applications

Overmolding offers exceptional value by improving product aesthetics, performance, and functionality. Whether through two-shot injection molding or co-injection molding, overmolding allows for innovative product designs with enhanced durability and cost-efficiency.

As a leading injection molding machine manufacturer, we provide comprehensive solutions for overmolding processes. Our advanced machines, including vertical and dual injection systems, help you achieve superior results in product development.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/

Previous news : Innovations at ChinaPlas: A Recap of Huarong's Injection Molding Solutions

Next news : Plastic injection molding material selection and their Molding Technology