What is IML? In Mold Labeling Process, Benefits, and Applications

2024-03-08 17:42:34

In mold labeling (IML) is revolutionizing the packaging industry, offering cost-effective, sustainable, and durable labeling solutions to industries like food and beverage, medical, and consumer goods. If you work with injection molding or blow molding, understanding IML Labeling's process and benefits can significantly impact your product's aesthetics and functionality.

In mold labeling, also called in mold labels or IML, is a method that involves the placement of a pre-printed polypropylene label (decorative film) into a mold prior to the formation of the plastic container. It makes the label merge with the molten plastic, creating a single product with a durable, high-quality label integrated into the container's surface.

Related product: In molding labeling machine - IML series

The process of in-mold labeling is unlike traditional methods, where labels are applied after production, applying a label or design to a product during the manufacturing process. How does in-mold labeling work? There are several options. The top three IML techniques are injection molding, blow molding, and thermoforming.

In mold labeling injection molding

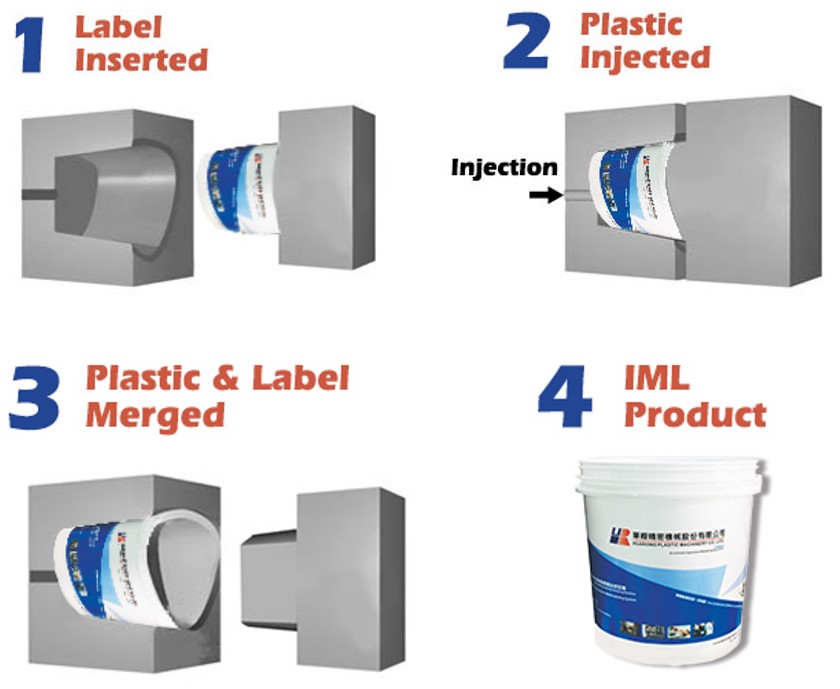

Injection molding is the most widely used in-mold labeling method. This process uses an to mold thermoplastics or thermosetting polymers by injecting heated and liquefied plastics or polymers into a mold. The plastic takes its shape as it cools, and the label is seamlessly integrated into the final product. Injection molding is widely used for products like plastic containers, butter or ice cream tubs, skin cream packaging, plastic paint buckets, computer keyboards, and cell phone keypads.

Injection molding is the predominant process used in IML. While seemingly simple, this process requires precise control of various variables to ensure the quality of the plastic components produced. By understanding the process and its parameters thoroughly, manufacturers can find suitable plastic component suppliers more easily.

Step 1: Choosing the right machine and mold

Selecting the correct injection molding machine, in-mold label machine and mold is crucial.

Step 2: Feeding and melting the thermoplastic

Injection molding equipment can be powered by electricity or hydraulics. Raw thermoplastic pellets are fed into the machine's hopper and gradually fed into the machine's barrel. The screw rotates, progressively heating and melting the thermoplastic until it becomes molten.

Step 3: Label Inserted

A pre-printed polypropylene label is taken by an in-mold label robotic arm and inserted into the mold. This ensures that the label is properly positioned for integration into the final product.

Step 4: Injecting the plastic into the mold

As the molten plastic reaches the end of the barrel, the gate, which controls the injection of plastic, closes. The screw advances, pulling a predetermined volume of plastic through and building pressure within, readying it for injection. The mold tool's two components are held tightly together under high pressure or clamp pressure.

Step 5: Holding and cooling

After most of the plastic is injected, pressure is applied for a specific duration, known as the "holding time." This time is crucial for ensuring proper plastic formation and tool packing. After cooling, the plastic conforms to the mold and bonds with the label.

Step 6: Finishing and ejection

After holding and cooling, pins or plates expel the pieces from the tool. These parts fall to the machine's bottom, where they are collected on a conveyor belt or in a compartment. The finished product is now a plastic product with a printed label.

Further reading related to injection molding process: Understanding the Injection Molding Process: A Complete Overview

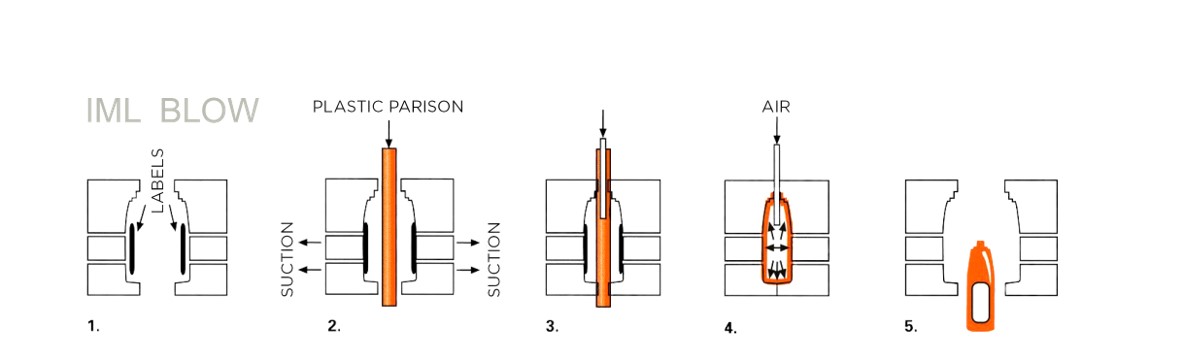

In mold labeling blow molding

Blow molding is the second most used technique for in mold labeling, especially for hollow plastic parts. In this process, manufacturers stretch or extrude a heated plastic mass to fit the shape of a mold. Air is then blown into the hollow tube to capture the mold's shape, resulting in a hollow plastic product with an integrated label. This method is commonly used for liquid containers like shampoo bottles, liquid soap containers, and containers for ketchup and sauces.

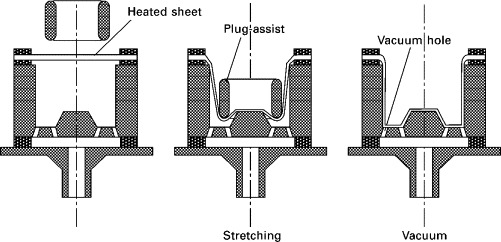

In mold labeling thermoforming

Thermoforming is slightly different from injection molding and blow molding. In thermoforming, manufacturers use heated plastic sheets that are formed into containers using a forming tool. The preprinted labels are incorporated into the plastic sheets during the forming process, resulting in labeled containers.

IML offers numerous benefits across industries, including increased branding options, cost-effectiveness, durability, and environment-friendly. It also helps prevent counterfeit products, ensuring product authenticity and security.

1. Increased branding and customization

IML offers high-quality, customizable labels that elevate brand image and attract consumers. Its rapid design changes and full-color printing capabilities ensure products stand out on shelves, providing a competitive edge in the market.

2. Cost-effectiveness and efficiency

IML simplifies labeling, reducing production costs and saving time. Its integration into the molding process eliminates extra steps, labor, and materials, boosting production efficiency and ensuring consistently high-quality labeled products.

3. Durability

IML creates a durable bond that resists peeling, cracking, and fading, even in challenging conditions such as humidity, temperature fluctuations, or harsh environments. This durability ensures that the label remains intact throughout the product's lifespan, maintaining its appearance and functionality.

4. Environment-friendly

IML containers are fully recyclable, making them eco-friendly. They do not require adhesives, reducing environmental impact and making them eligible for post-consumer recycled (PCR) products.

In-mold label typically utilizes materials compatible with the injection molding process and can bond well with the molded product. The most commonly used materials for in-mold labeling are:

- Polypropylene (PP): PP is one of the most widely used materials for in-mold labeling due to its excellent molding properties and label compatibility. It offers good stiffness, impact resistance, and chemical resistance.

- High-Density Polyethylene (HDPE): HDPE is another popular choice for in-mold labeling. It provides good stiffness and strength, along with resistance to chemicals and moisture.

IML is widely used in food and beverage packaging, medical and healthcare products, automotive and industrial parts, and consumer goods. Its efficiency, cost-effectiveness, and customizability make it suitable for various industries.

- Food and beverage packaging: containers like bottles, cups, and lids with high-quality graphics, ensuring durability and resistance to fading and peeling.

- Medical and healthcare Products: medical devices and products like inhalers, syringes, and vials, meeting industry requirements for sterility and tamper-evidence.

- Consumer goods: food packaging, cosmetics, household, and personal care products, providing durable and visually appealing labeling options.

The production of 16 Liters Painting Bucket video is below:

What are some design considerations when using in mold labeling?

When using IML, consider your container requirements, container shape, container size, surface consistency, and printing location to ensure a successful labeling process.

- Container shape: like round, square, or…

- Container size: like 5 oz. container

- Surface consistency: like smooth, textured, or…

- Printing location: like container body or lid

How thick is in mold labeling?

In-mold labeling typically uses label materials like polypropylene or polystyrene, with a thickness ranging from 15 to 40 micrometers (µm).

In-mold labeling is a versatile, cost-effective, and sustainable solution for various industries. Understanding the benefits and process of IML can help you make informed decisions and achieve high-quality, visually appealing labeled products. If you're looking for an IML service, consider Huarong, a leading injection molding machine manufacturer with exceptional in-mold labeling capabilities. If you need in-mold labeling, please feel free to contact Huarong.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777 #521

- Address: No.21-6, Zhongzhou,Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/

Previous news : Hair Clip Making Machine: A Success Story in Injection Molding Automation

Next news : What is 2K Injection Molding? 2K Molding Equipment and Advantages