Injection Molding Machine Lubrication System: Engine Behind Efficiency, Precision, and Longevity

2025-08-21 08:46:03

The lubrication system in an injection molding machine isn’t merely for maintenance; it is essential for ensuring stable, high-quality production. Although often overlooked, this system is crucial for maintaining peak machine efficiency, preventing unexpected outages, and ensuring the dimensional accuracy of molded parts. As demands for precision, uptime, and energy efficiency grow, having a well-designed lubrication system in injection molding machines has become indispensable—it is now a critical component. This guide explores lubrication systems in injection molding machines, focusing on functions, components, challenges, and innovations, helping manufacturers optimize performance and extend equipment lifespan.

Injection molding machines undergo extreme mechanical stress during continuous operation. From toggle clamps subjected to cyclic loads to ejector pins operating at high speed, components endure relentless wear, heat, and friction. A proper lubrication system combats these forces through:

- Friction reduction

- Heat dissipation

- Contaminant flushing

- Corrosion prevention

Without adequate lubrication, wear accelerates, machine accuracy degrades, and production defects become more frequent. In worst cases, parts seize or fail, causing costly downtime. Thus, a stable lubrication system is essential for ensuring consistent product quality and protecting your equipment investment.

Further reading:Clamping Force in Injection Molding: Formula & Optimization Tips

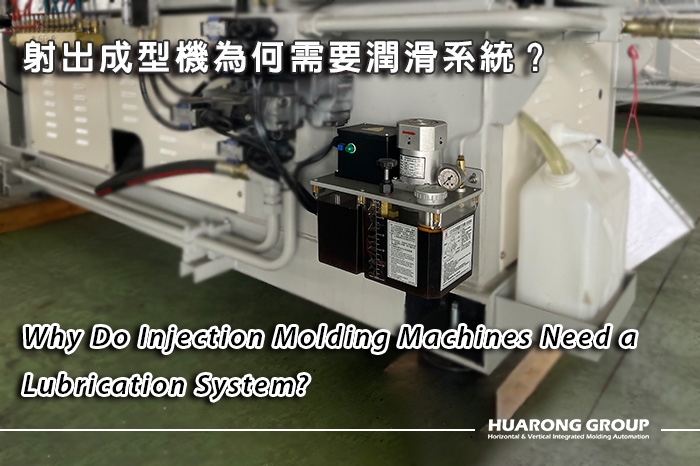

Modern machines use centralized automatic lubrication systems, engineered for precision and efficiency. These systems work during production, eliminating the need for manual oiling or machine stoppage.

- Lubrication Pump – Generates pressure to distribute lubricant.

- Distributors & Injectors – Regulate the volume and timing for each lubrication point.

- Piping & Fittings – Channel oil to the mold clamping unit, guide rails, ejectors, and screw.

- Pressure Monitoring System – Detects blockages, leaks, or pressure drops.

- Oil Reservoir with Filter – Stores and filters lubricant to ensure consistent quality.

- Pump activation builds pressure in the main line.

- Distributors allocate flow based on each component's need.

- Injectors deliver lubricant with precise timing and dosage.

- Sensors verify flow and pressure, ensuring every point is serviced before the next cycle.

Injection molding machines vary in size, speed, and application. As such, several lubrication systems are used:

| System Type | Features | Applications |

|---|---|---|

| Single-line / Dual-line | Simple, reliable, easy maintenance | Small to medium machines |

| Progressive System | Sequential lubrication; detects blockage easily | High-precision or high-cycle applications |

| Positive Displacement Injector | Individual point control prevents over/under lubrication | Precision machines and large equipment |

| Oil-Air Lubrication | Oil mixed with air for cooling and lubrication | High-speed or high-temperature applications |

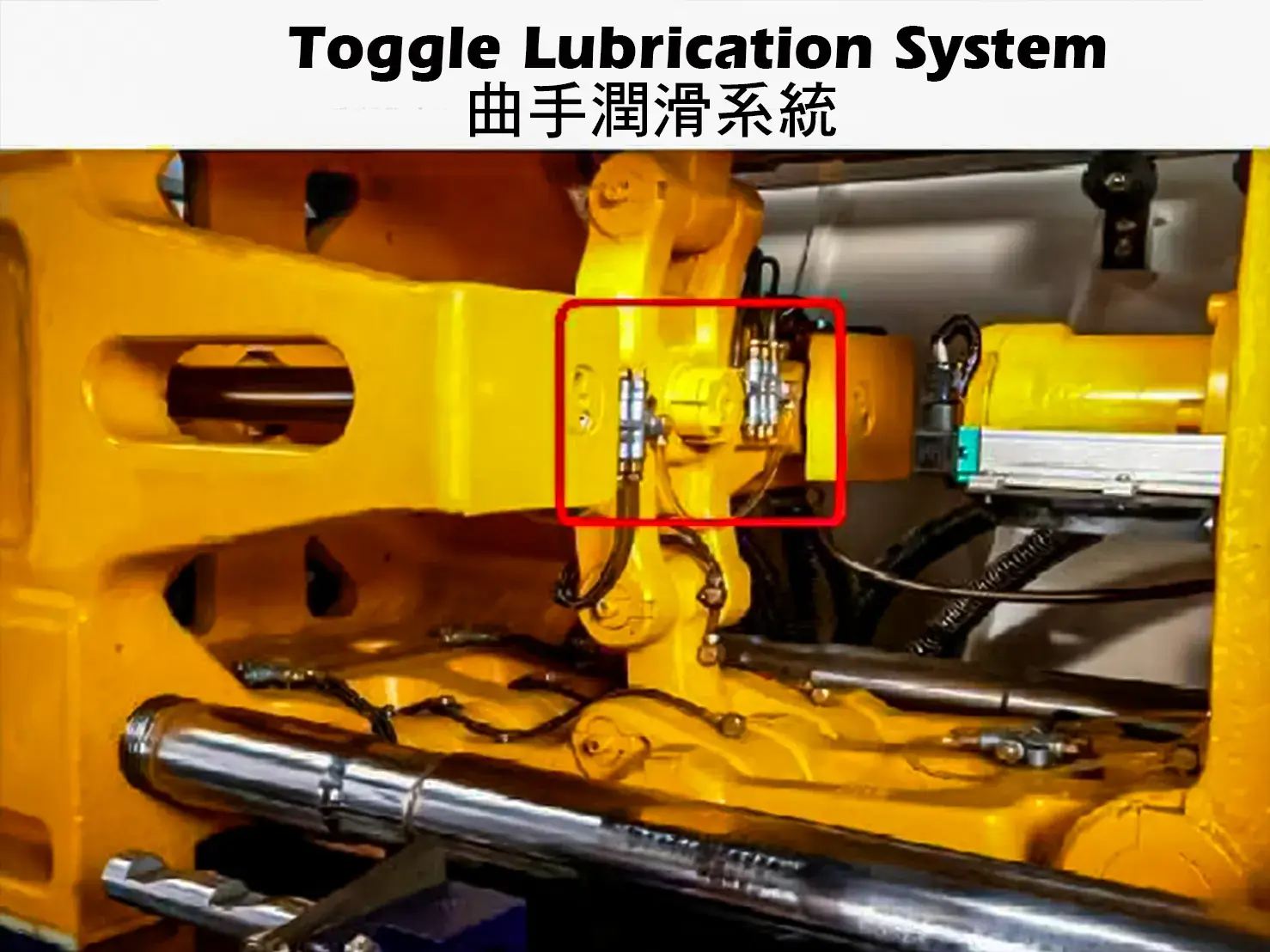

Each component in an injection molding machine has unique tribological demands. A "one-size-fits-all" approach to lubrication is inefficient and potentially damaging. Here’s how different areas require specific solutions:

| Component | Lubricant Type | Reason |

|---|---|---|

| Toggle Clamp System | High-viscosity EP grease with molybdenum disulfide (MoS₂) | Handles high pressure, resists galling |

| Linear Guides / Screws | Low-viscosity anti-wear hydraulic oil (ISO VG 68) | Ensures smooth, accurate movement |

| Ejector Pins | Heat-resistant, non-staining oil or light grease | Prevents burn marks or mold contamination |

| Hydraulic Circuit | Multi-grade hydraulic oil with high viscosity index | Maintains stable pressure across varying temps |

Many surface and dimensional defects stem from lubrication failures. Strategic lubrication helps eliminate these problems at the source:

Flash refers to excess material that seeps out of the mold cavity, forming a thin fin along the parting line. Dimensional instability relates to parts that deviate from their intended size or shape—both are costly defects that often result from poor machine mechanics rather than mold issues.

- Worn toggle pins or bushings in the clamping mechanism result in insufficient clamping force.

- Inadequate lubrication leads to metal-on-metal friction, accelerated wear, and loss of clamping parallelism.

- Over time, this mechanical play prevents the mold from fully sealing, allowing molten material to escape under pressure.

A well-maintained injection molding machine lubrication system ensures that the clamping unit, including toggle links, bushings, and guide pins, operates smoothly under full load. This:

- Preserves full clamping force,

- Maintains mold alignment during high-pressure injection,

- Prevents premature component wear,

- Reduces mold separation that causes flash,

- Improves dimensional repeatability over thousands of cycles.

Splay marks appear as silver streaks or cloud-like patterns on molded parts, while shrinkage streaks show as dark lines or charred patches. Though often attributed to material or drying issues, lubrication also plays a critical behind-the-scenes role in avoiding these cosmetic and structural defects.

- Insufficient lubrication in the screw drive or barrel leads to excessive friction and localized heat buildup.

- High friction accelerates thermal degradation of plastic resin, forming gas bubbles or burnt material.

- Inadequate lubrication in fast-moving parts can also cause inconsistent screw backpressure or shear rates, exacerbating these defects.

- Minimizes internal friction in the plasticizing unit,

- Stabilizes barrel temperature and backpressure,

- Prevents resin degradation that produces splay or burning,

- Ensures smooth and consistent screw rotation and retraction.

One of the most critical measures of molding quality is the ability to produce consistent part weight and dimensions, cycle after cycle. Deviations in shot weight often indicate mechanical inconsistencies caused by degraded motion paths or unstable machine feedback.

Further reading: Injection Molding Cycle Time: The Key to Faster and Smarter Manufacturing

- Linear guides or ball screws that lack lubrication can cause the moving platen or injection unit to exhibit jerky or uneven movement.

- This disrupts melt flow consistency and precise injection velocity during both the injection and holding phases.

- Result: Variations in cavity packing pressure and cooling profiles, which directly impact part weight and shrinkage behavior.

- Smooth and synchronized movement of key mechanical components,

- Shot-to-shot repeatability in injection speed and holding pressure,

- Reduced wear on linear guides and mechanical linkages,

- Minimized machine vibration or "stick-slip" behavior during injection.

Despite automation, failures can occur in a lubrication system. Here are typical issues and their countermeasures:

| Problem | Cause | Solution |

|---|---|---|

| Low oil pressure | Worn pump or low oil level | Refill oil, inspect or replace pump |

| Blockage or leaks | Clogged filter, damaged pipes | Clean or replace as needed |

| Uneven lubrication | Faulty distributor or injectors | Disassemble, clean, or replace |

| Sensor malfunction | Wiring or switch failure | Test and replace defective components |

| Oil degradation | Mixing oils, low-quality lubricant | Use proper oil, add filtration and monitoring |

- Daily – Visual leak check, confirm sensor feedback.

- Weekly – Clean rails, inspect grease color, check reservoir level.

- Monthly – Inspect divider movement, log pump current.

- Quarterly – Conduct oil analysis (FTIR, TAN), change filters.

- Annually – Drain and clean reservoir, rebuild pump, recalibrate sensors.

Further reading: Injection Molding Machine Maintenance PDF and Checklist

In the world of injection molding, precision and reliability are everything. The lubrication system is not just an engineering afterthought—it’s the enabler of both. Whether you’re molding automotive parts, medical devices, or consumer goods, ensuring your injection molding machine lubrication system is optimized and intelligent will protect your production line and boost your bottom line.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/