High Pressure Injection Molding: Benefits, Pressure, Applications

2025-05-29 13:22:08

High pressure injection molding is the preferred manufacturing solution for precision, repeatability, and efficiency in plastic production. Central to high-performance molding is injection pressure, which pushes molten resin into complex cavities and thin walls before cooling. This article explores the principles, benefits, challenges, and future innovations of high pressure injection molding in today’s competitive manufacturing landscape.

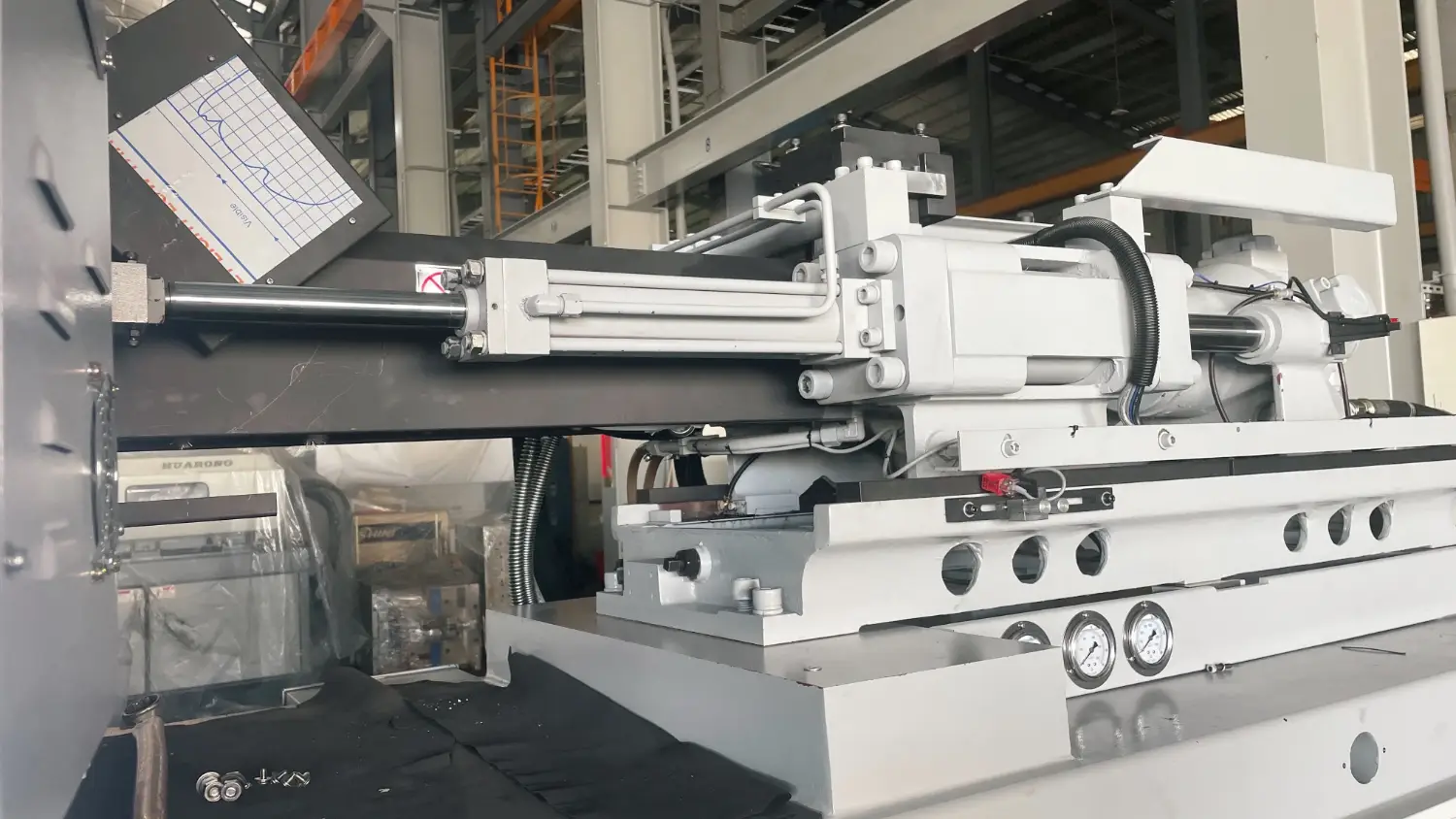

High pressure injection molding is a process that uses a machine capable of generating injection pressures of 1,800 kg/cm² or higher (≈176 MPa). Unlike conventional machines focused on large shot volumes, high-pressure injection molding systems are engineered to maximize injection force, ensuring molten resin fills complex cavities quickly and thoroughly, even through long and thin flow paths.

Injection molding machines can be categorized by maximum pressure capacity:

- Standard pressure: 1,200–1,700 kg/cm² (≈118–167 MPa)

- High pressure: ≥1,800 kg/cm² (≈176 MPa)

- Ultra high pressure: 2,500–3,000 kg/cm² (≈245–294 MPa) for highly demanding applications

Injection pressure is closely tied to the Length-to-Thickness ratio (L/t)—a measure of how far molten plastic must travel relative to wall thickness. A higher L/t demands higher pressure to maintain flow before the melt solidifies.

In high pressure injection molding, this ensures complete filling even in narrow, intricate geometries. It's particularly vital for thin-wall designs, deep ribbing, or parts with multiple gate locations. Controlled pressure avoids premature freeze-off and ensures superior dimensional accuracy.

A properly designed high pressure injection molding system delivers several key performance advantages across diverse plastic part designs.

With higher injection pressure, machines sustain melt momentum across long flow paths and tight channels. This reduces flow hesitation, eliminates short shots, and supports uniform fill distribution—even in large or multi-cavity tools with complex runner layouts.

Further reading: Short Shot in Injection Molding: Causes, Detection & Solutions

High pressure injection molding is ideal for parts under 1 mm wall thickness, where fast filling and high force are needed to avoid surface defects and incomplete packing. Common examples include:

- Thin-wall packaging (caps, trays, IML containers)

- Precision medical components (syringe barrels, inserts)

- Consumer electronics (battery covers, lenses)

Engineering-grade resins, such as PBT+GF, PA6+GF, and PC-FR, exhibit higher flow resistance. High-pressure injection molding enables these injection molding materials to fill the cavity fully, improving weld lines strength and surface finish while reducing the risk of fiber breakage.

Machines built for high pressure typically include:

- Longer L/D screw ratios (Length-to-Diameter) for better melt homogenization

- Reinforced barrels and injection cylinders

- Optimized heating zones for faster response

This improves long-term performance, reduces component wear, and expands compatibility with a wide range of resins and part types.

While high pressure injection molding enhances capability, it introduces mechanical and process control challenges that require thoughtful system integration.

Higher cavity pressure demands increased clamping force to maintain mold alignment. Undersized clamping results in parting line flash or mold deformation. Selecting the correct tonnage-to-part-area ratio is essential.

Further reading: Choosing the Right Injection Molding Machine: A Comprehensive Guide

High pressure leads to faster wear on screws, barrels, and non-return valves. Countermeasures include:

- Hardened steel components

- Periodic maintenance intervals

- Pressure monitoring for predictive service alerts

Fast-filling under pressure can trap air and create burn marks. Mold designers must incorporate:

- High-efficiency venting near knit lines

- Conformal cooling circuits

- Gate and runner designs that minimize pressure loss

Further reading: Common Injection Molding Defects: Causes, Types, and Solutions

High pressure injection molding is used in precision-critical and high-volume sectors including:

- Packaging: Thin-wall IML containers, disposable cups

- 3C electronics: Camera parts, USB housings, lens frames

- Medical: Diagnostic kit cases, syringe plungers, IV sets

- Automotive: Switch panels, trim parts, lighting bezels

- EV & batteries: Long flow-path housings, BMS covers

- Storage tools: Structural boxes with thick walls

- Home appliances: Washing machine drums, fan blades, casing panels

The next evolution of high pressure injection molding integrates smart monitoring, advanced materials, and sustainable manufacturing efficiency.

Modern injection machines equipped with real-time pressure sensors and network connectivity enable:

- Data-driven production analytics

- Automated pressure tuning

- Predictive maintenance based on pressure deviations

Integration with smart factory systems ensures traceability, optimizes uptime, and maintains consistent part quality across production shifts.

Related product:Smart Factory Management - HFM

Incorporating microcellular foam molding into high-pressure processes introduces gas (e.g. N₂) into the melt to form a microbubble structure. The result:

- 15–20% part weight reduction

- 30–50% clamp force savings

- Enhanced energy efficiency with faster cycle time

Ideal for structural components needing light weight without sacrificing rigidity.

Further reading:Microcellular Foam Injection Molding: Achieving Maximum Weight Reduction and Dimensional Stability

Related technology:Microcellular Foam Injection Molding Technology

High pressure injection molding is the foundation for competitive, high-precision plastic manufacturing. From ultra-thin electronics to structural automotive parts, mastering injection pressure enables manufacturers to consistently and efficiently mold complex, accurate, and robust parts.

By optimizing melt flow, pressure profiles, and machine capability, manufacturers achieve faster cycles, better repeatability, and improved part quality—all essential in a cost-driven, high-performance production environment.

At Huarong, our injection units feature larger capacities to achieve higher injection pressure for demanding applications. We prioritize pressure over volume, as it gives our machines an edge for thin-walled, high-flow-resistance, and high-precision tasks. The result? Faster, more stable filling and better product integrity.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist.., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/