Thick Wall Injection Molding: Powerful Engineering Control for High-Structural Plastic Components

2025-12-18 14:14:02

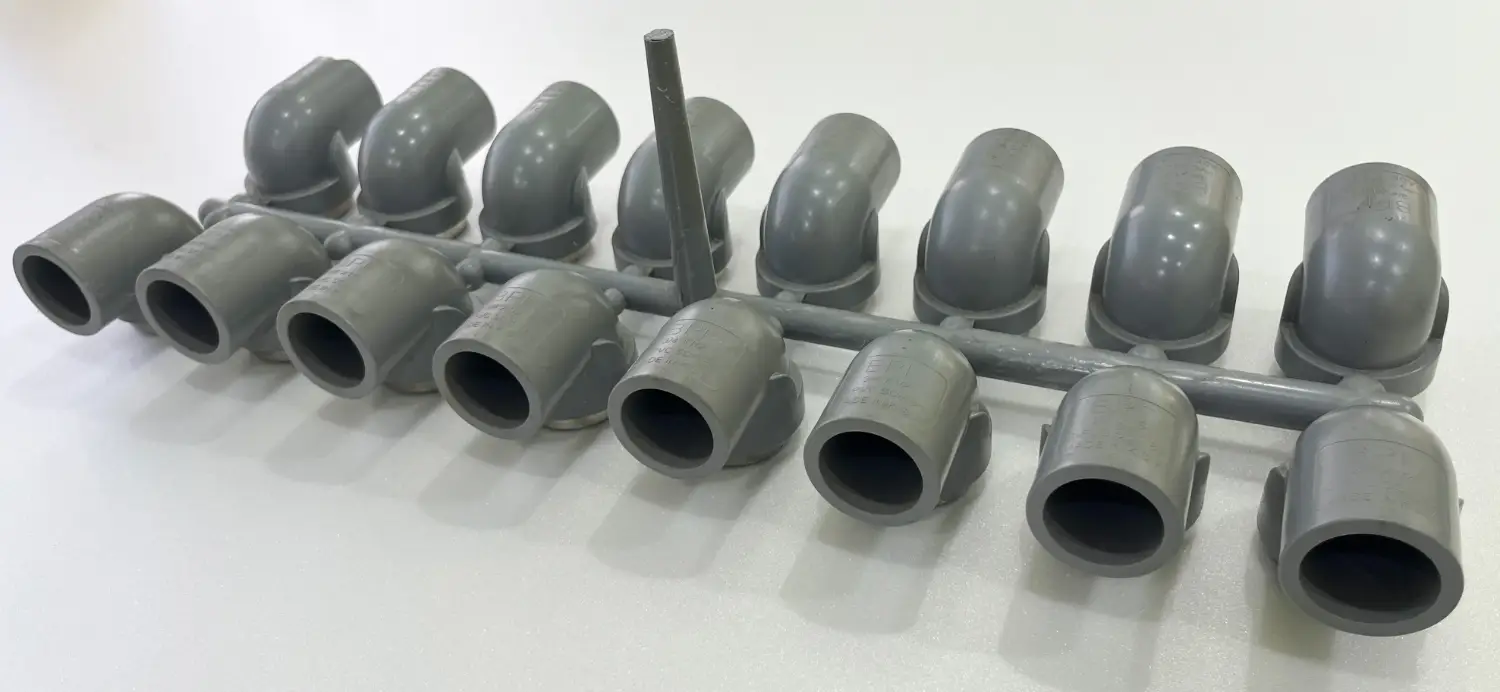

Thick Wall Injection Molding is a specialized manufacturing process used to produce plastic components that demand high structural strength, dimensional stability, and long-term mechanical reliability. Unlike thin-wall molding, where speed, material efficiency, and short cycles dominate, this process prioritizes controlled filling, prolonged cooling, and stable pressure transmission across large cross-sections of plastic.

In most applications, wall thicknesses exceed 3–4 mm and can reach 10 mm or more, depending on structural load requirements and part geometry. These parts often replace metal components or integrate multiple functions into a single molded structure, reducing assembly steps and improving durability.

Thick Wall Injection Molding refers to injection molding where the part walls are much thicker than typical consumer parts. In most industries, anything above 3 mm counts, and many structural parts go beyond 5 mm.

These parts are made thicker to achieve strength and stiffness, but thickness also makes manufacturing harder because the core cools slowly. That slow cooling is what drives longer cycle times and more defect risk.

- Industrial machine housings and frames

- Load-bearing brackets and supports

- Large mechanical casings and containers

- Automotive structural and semi-structural components

- Electrical enclosures with impact or fire-resistance needs

- Durable consumer product bases and reinforcements

Thick-wall parts behave differently than thin parts because they store more heat and shrink more as they cool. The design must support strength without creating molding problems like internal voids or surface sinks.

In thick-wall parts, mechanical performance is achieved through material mass and cross-sectional geometry. Increased wall thickness improves stiffness, impact resistance, and fatigue life. However, this benefit only holds when internal structure is free from voids and residual stress. Poor packing or uneven cooling can reduce effective strength even if the part appears dimensionally correct.

Heat dissipation is the dominant challenge in thick-wall molding. Cooling time increases with the square of wall thickness, making thick regions the primary limiter of cycle time.

In conventional injection molding, cooling typically accounts for 50–80% of total cycle time. In thick-wall molding, this ratio often exceeds 80% because heat trapped in the part's core cannot be removed efficiently through the mold surface alone. Without an optimized cooling design, internal temperature gradients remain high, causing delayed shrinkage, sink marks, or void formation after ejection.

Thicker walls increase flow length and melt resistance. Molten injection molding material must remain above its solidification temperature long enough to fill the cavity and allow effective packing. This requires coordinated control of:

- Injection pressure and injection speed

- Melt temperature uniformity

- Mold temperature stability

- Gate cross-sectional area

- Holding pressure duration relative to gate freeze time

Thick-wall molding and thin-wall molding look similar on the surface, but they are driven by different priorities. Thin-wall focuses on speed and lightweighting. Thick-wall focuses on stability, controlled cooling, and reliable packing.

| Design Aspect | Thick Wall Injection Molding | Thin Wall Injection Molding |

|---|---|---|

| Typical Wall Thickness | > 3 mm | < 1.5 mm |

| Primary Objective | Structural durability | Lightweighting |

| Cooling Time | Long, dominant | Short |

| Injection Speed | Moderate | Extremely high |

| Pressure Control | Stable, extended | Rapid switching |

| Material Selection | Structural polymers | High-flow resins |

| Equipment Focus | Rigidity and torque | Speed and acceleration |

| Design Aspect | Thick Wall Injection Machines | Thin Wall Injection Machines |

|---|---|---|

| Primary Control Focus | Pressure stability | Speed response |

| Injection Speed | Moderate | Extremely high |

| Holding Phase | Long and critical | Short |

| Cooling Strategy | Multi-zone precision cooling | High-flow cooling, short cycle |

| Structural Rigidity | High (reinforced platen and clamping unit) | Moderate |

| Screw Design | High torque, uniform melt plasticizing | High shear, fast recovery |

Most thick-wall defects come from one simple reality: the outside freezes first, while the inside is still hot and shrinking. If the mold can’t keep feeding material into the part during that shrinkage, voids and sink marks form.

As wall thickness increases, the gate freezes earlier relative to the core cooling time. Once the gate freezes, additional holding pressure cannot compensate for volumetric shrinkage in the core. This leads to:

- Internal voids

- Sink marks on surface

- Density gradients

- Reduced mechanical strength

Sink marks occur when surface layers solidify while the internal core continues to shrink. In thick sections, this mechanism is amplified. Internal voids form when the core shrinks without sufficient melt compensation.

Engineering solutions include:

- Larger gate dimensions

- Multiple gates feeding thick zones

- Extended holding pressure

- Mold temperature optimization

- Structural coring instead of solid mass

- Microcellular Foam Injection Molding for very thick regions

Further reading: Microcellular Foam Injection Molding: A Complete Guide to Lightweight and Energy-Efficient Production

Uneven cooling across thick and thin regions causes differential shrinkage, leading to warpage. Residual stress also accumulates when packing pressure is excessive or cooling gradients are steep. Controlled cooling symmetry is more important than absolute cooling speed in thick-wall molding.

Not all plastics behave the same when walls get thick. Some shrink a lot, some hold heat longer, and some become stress-sensitive. That means resin choice must consider thermal behavior and packing response, not just strength or cost.

- PP & PE: Higher shrinkage; often need longer holding

- ABS: Good balance of flow and dimensional predictability

- PC: Holds heat longer; needs stable mold temperature

- PA (Nylon): Moisture affects shrinkage and dimensions

- POM: Can build internal stress if cooling is uneven

- Filled resins: Stiffer but often harder to cool evenly

Further reading: Understanding the 10 Most Common Injection Molding Materials

Thick-wall molding relies on stable pressure delivery and consistent melt quality. It’s less about ultra-fast injection and more about repeatability across long hold and long cool phases.

If the machine lacks torque, clamp stability, or process consistency, the part may look fine but fail internal quality targets.

Thick-wall parts require stable pressure transmission rather than extreme speed. Machines must provide sufficient clamping force to prevent mold separation during long holding phases. High torque plasticizing systems ensure consistent melt quality for large shot sizes.

Large-diameter screws with optimized compression ratios are essential. Melt homogeneity is more critical than shear speed. Poor plasticization leads to density variation and weak internal bonding in thick sections.

Multi-zone mold temperature control is essential. Thick areas require localized cooling optimization to prevent hot spots. Cooling circuits must follow thickness distribution rather than uniform spacing.

In thick-wall molding, tooling design often decides success before the machine ever runs. The gate must stay open long enough, the runners must deliver material evenly, and the tool must remain rigid under sustained pressure. This is where many thick-wall projects win or lose on cycle time and defect rate.

- Gate thickness should approach 70–80% of wall thickness

- Fan or edge gates reduce localized shear

- Multiple gates may be required to reduce flow length

- Runner balance must match thermal mass, not geometry

Thick-wall parts trap air more easily. Adequate vent depth and distribution prevent burn marks and incomplete filling.

High internal pressure during long packing phases demands rigid mold bases and platen support to prevent deflection that causes flash or dimensional drift.

Most shops consider above 3 mm thick-wall, and structural parts commonly exceed 5 mm.

Because the core cools slowly and cooling time rises sharply with thickness.

Usually gate freeze before the core solidifies, preventing shrinkage compensation.

Thick Wall Injection Molding is a controlled engineering process that balances structural performance with thermal and pressure management. Success depends on understanding heat transfer, packing limitations, material behavior, and machine rigidity as a unified system. When properly engineered, thick-wall molding enables plastic components to replace metal structures, reduce assembly complexity, and deliver long-term mechanical reliability in demanding industrial applications.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/