Successfully Concludes K Show 2025, Showcasing Injection Molding and Automation

2025-10-23 08:56:47

Düsseldorf, Germany — Huarong Group, a leading injection molding machine manufacturerfrom Taiwan, has successfully concluded its participation at K Show 2025, the world’s most influential plastic and rubber exhibition. This year, Huarong delivered a fully integrated demonstration combining injection molding, automated assembly, and smart packaging—perfectly aligning with the K Show vision of complete manufacturing solutions and smart production ecosystems. The exhibition drew strong global attention and generated overwhelmingly positive feedback from visitors, partners, and industry professionals.

As one of the exhibitors in the Taiwan Pavilion, Huarong participated in the official opening ceremony hosted on the first day of the show, where delegates and guests gathered to highlight Taiwan’s presence at K Show 2025. Taiwan’s Representative to Germany, Mr. Jhy-Wey Shieh, later visited the Huarong booth, expressing recognition for our system integration capabilities and innovative achievements. His visit underscored both Taiwan’s manufacturing strength and Huarong’s growing influence on the global stage.

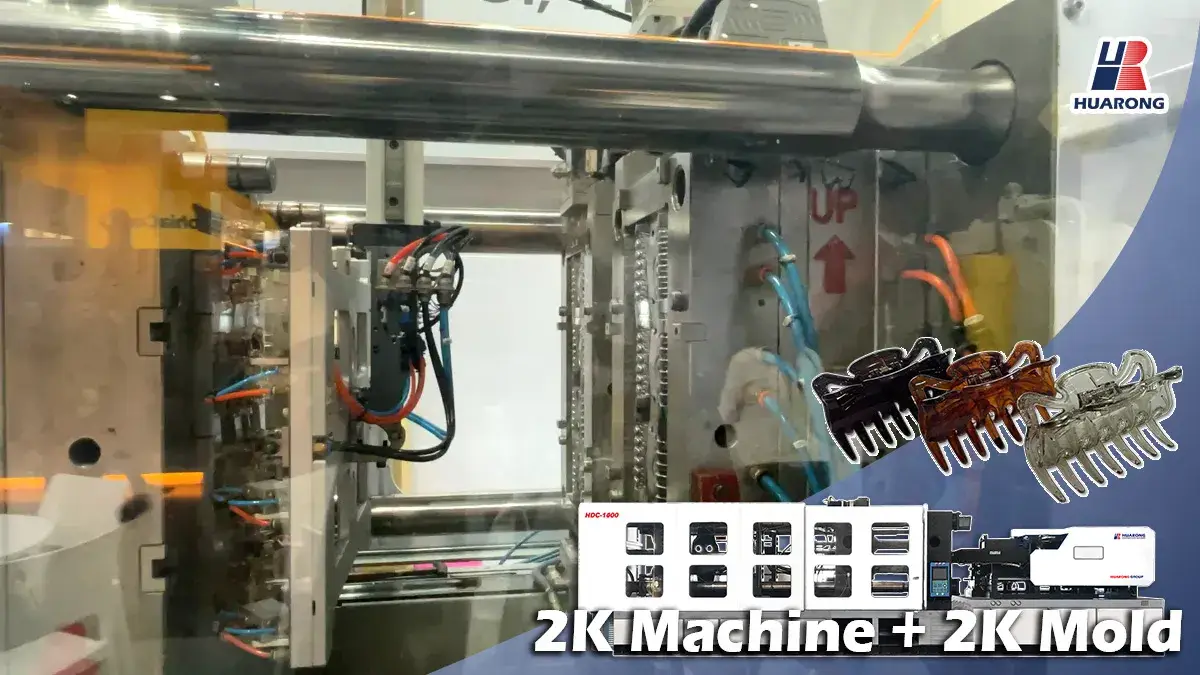

One of the most popular show highlights was Huarong’s fully automated double-shot hairclip production line, featuring a functional anti-slip design and a striking amber-like surface created through advanced screw and molding technology. The live-produced clips became a sensation across the show floor, with Huarong distributing 7,000+ sets (14,000+ individual clips) to attendees throughout the week.

By the final exhibition days, staff members in Hall 12 and at the East Entrance could be seen wearing the hair clips — a heartwarming sign of real product acceptance. What touched the Huarong team even more was watching not only women, but many men as well line up, saying they wanted to bring a thoughtful gift home to their wives, daughters, girlfriends, or granddaughters. The hair clip went beyond a giveaway — it became a symbol of connection, craftsmanship, and brand warmth.

On October 12, K Show experienced a rare and unexpected event — a major power outage across Halls 12 and 13, lasting over 30 minutes. Many exhibitors stated that in more than a decade of attending K, they had never witnessed such an incident.

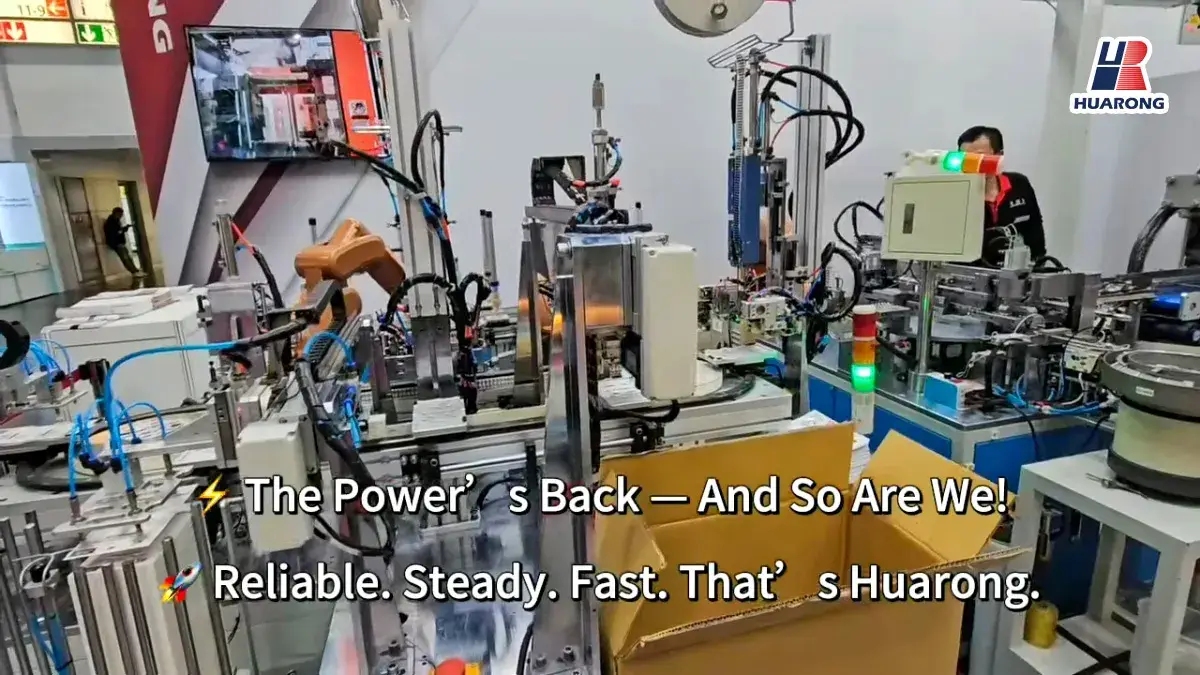

Once power returned, Huarong demonstrated true engineering resilience. Our injection molding machine and automation line were restored and back in full production within just 20 minutes, proving our core value in real-world testing conditions:

This incident became a memorable moment of the exhibition, further reinforcing the stability, precision, and dependability of Huarong’s engineering.

As one of the few exhibitors demonstrating a fully automated production cell, Huarong’s booth became a focal point for manufacturers seeking complete solutions instead of standalone machines. The hair-clip line showcased not only molding capability, but the future of connected, automated, and waste-reduced production.

Visitors were impressed by how seamlessly the system synchronized molding, automated pick-and-place handling, assembly, and smart packaging. Many praised the refined movement, cycle-time stability, and hair-clip output consistency—proving that automation is not merely an addition, but a multiplier of molding performance.

The anti-slip structure and amber-like texture of the hairclips drew continuous attention, with attendees often commenting that the surface quality “didn’t look like it came directly off the mold.” The demonstration became a tangible testament to Huarong’s ability to achieve fine surface definition, repeatability, and stable dual-material bonding—all in a live environment.

Related product: Double Injection Molding Machine – HDC Series

The co-exhibited Dry Molded Fiber technology—from Swedish innovator PulPac—introduced a next-generation alternative to single-use plastics. Using dry-fiber forming with ultra-low water consumption and fast cycle speeds (around 3.5 seconds), the process enables rigid, fiber-based products with significantly reduced CO₂ emissions compared to conventional plastic forming. (pulpac.com)

This collaboration sent a strong message: Huarong is committed not only to automation and productivity, but also to sustainable and responsible manufacturing—helping customers align with future global regulations and ESG goals.

The success at K Show 2025 marks a new milestone for Huarong Group. With strong momentum, global recognition, and deepened customer engagement, the company will continue expanding its footprint across international markets while advancing its technology in automation, system integration, and smart injection molding.

For cooperation, consultation, or equipment inquiries, please contact us:

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/