Injection Molding Auxiliary Equipment: A Beginner’s Guide

2025-09-12 13:10:35

Injection molding is more than just the machine—it’s a complete production system. Many beginners assume that buying an injection molding machine alone guarantees quality production. However, without the right auxiliary equipment, you may encounter problems such as part warpage, prolonged cooling times, inconsistent color, or unnecessary waste.

Whether you're new to the plastics industry or setting up a new production line, this guide introduces all the essential devices through the 4 essential categories of injection molding auxiliary equipment—explained in a clear, beginner-friendly way.

A common mistake is underestimating the importance of drying. Even invisible moisture can destroy part quality, especially with hygroscopic materials like PET and PC. This system ensures your injection molding material is clean, dry, correctly mixed, and consistently fed into the injection molding machine.

Many plastic resins (like PET, PC, and PA) are hygroscopic, meaning they absorb moisture from the air. If not adequately dried, this moisture can cause defects such as bubbles, hazing, or silver streaks in the final product.

- Hot Air Dryer: Uses heated air to dry the resin. It's suitable for materials with low moisture absorption, such as PP and PE.

- Dehumidifying Dryer: Uses a sealed, low-dew-point air circulation system to remove internal structural moisture from the resin. This equipment is a must for materials that "drink water," like PC, PA, and PET.

An auto loader automatically conveys plastic resin from a material bin or storage tank into the dryer or directly to the machine hopper.

- Function: Maintains a continuous supply of material without manual scooping or feeding.

- Types: Single-stage (direct feed) or two-stage (hopper to dryer to machine).

A masterbatch doser precisely meters and blends a small amount of color concentrate (or additive) into the base resin before plasticizing.

- Function: Ensures consistent color quality by maintaining exact pigment ratios.

- Types: Volumetric (simpler, lower precision) and gravimetric (higher precision, weight-based).

Many beginners confuse chillers with mold temperature controllers. While both deal with temperature, one cools and the other heats. Understanding their roles is crucial for avoiding defects and reducing cycle times. The temperature of the mold directly impacts the product's dimensional stability, surface quality, and molding cycle time.

Responsible for heating or cooling the mold to maintain a stable temperature. It's highly effective at improving a product's dimensions, gloss, and preventing warpage. MTCs come in two main types based on their heating medium:

- Water-based: Operates in the range of 30°C to 120°C and is suitable for most molds.

- Oil-based: Operates from 120°C to 300°C and is used for high-temperature engineering plastics.

Further reading: Complete Guide to Mold Temperature Controllers:Precision Control for High-Quality Injection Molding

A hot runner controller manages the temperature of individual heating zones inside the hot runner manifold of the mold. It is not the same as a mold temperature controller.

- Function: Delivers precise heating to sprue bushings, manifolds, and gate nozzles.

- Multi-Zone Control: Often required for multi-cavity molds or valve gate systems.

- Features: PID control, temperature monitoring, alarms, and auto-tuning.

A cooling tower is an open-loop system that removes heat from the water and provides a general-purpose, circulating cooling water supply for the entire factory system. It's an economical and stable option, making it a standard feature in most factories and used in molding machines, chillers, oil coolers, and other equipment.

A chiller provides low-temperature water to cool the mold, hydraulic oil, or auxiliary equipment.

- Air-Cooled Chiller: Uses fans to dissipate heat—no need for a cooling tower. Ideal for small factories or space-limited environments.

- Water-Cooled Chiller: Uses water from a cooling tower for heat exchange—more energy-efficient but requires infrastructure.

Further reading: Chiller for Injection Molding: Cooling Stability as the Foundation of Injection Molding Performance

Many assume molding ends after ejection. But what happens after the part leaves the mold is just as important for quality and logistics. After a part is ejected from the mold, post-molding handling systems are responsible for finishing touches, such as sprue separation, visual inspection, product transport, and staging for packaging. These systems ensure that the molded product meets aesthetic, dimensional, and functional requirements, while also streamlining logistics.

A gate cutter removes the sprue or runner from the molded part. It can be operated manually, pneumatically, or integrated with robotic automation.

- Function: Separates non-functional sprues/gates cleanly without damaging the product.

A vision inspection system uses industrial cameras and image processing software to automatically detect part defects.

- Function: Identifies visual or dimensional flaws such as short shots, flash, discoloration, warpage, or deformation.

A conveyor belt transports molded products from the ejection point to the next stage, whether it is inspection, packaging, or recycling.

- Function: Ensures a steady flow of parts from the machine to the downstream processes.

- Types:

- Flat belt (standard)

- Incline or Z-type for vertical elevation

- Modular or cleated belts for controlled spacing

- Integration: Often paired with robot arms for full-cycle automation.

Automation systems include equipment that integrates with the injection molding machine to handle tasks like part removal, label insertion, product transfer, and even part assembly. Automation in injection molding helps achieve stable quality, improved efficiency, and reduced labor dependency, and opens the door to Industry 4.0 smart manufacturing.

A robot arm, also known as a manipulator, is a programmable mechanical device that automates various stages of part handling after injection. Commonly used in high-speed or high-precision production where manual removal is inefficient or unsafe.

- Function: Extracts finished parts, inserts metal or film components, performs gate cutting, or places parts on conveyors or assembly lines.

- Axis Types:

- 3-axis Cartesian robots (basic in/out + up/down motion)

- 5-axis or 6-axis articulated robots for complex movements

Related product: Manipulator arm– HRB Series

Related article: Comprehensive Guide to Injection Molding Robots: Automate Your Production Process

An in-mold labeling (IML) system automates the process of placing pre-printed labels or films into the mold before the injection process. Once injected, the molten plastic bonds with the label, producing a finished decorated part in one cycle.IML reduces post-molding printing costs, increases production speed, and creates tamper-proof, high-quality labeling.

- Function: Robotic arms or IML feeders pick up labels, position them accurately inside the cavity, and release them before the mold closes.

- Application: Widely used in packaging (yogurt cups, instant food containers, drink lids), cosmetics, and branded retail products.

Related product: In Mold Labeling Machine – IML Series

Related article: What is IML? In Mold Labeling Process, Benefits, and Applications

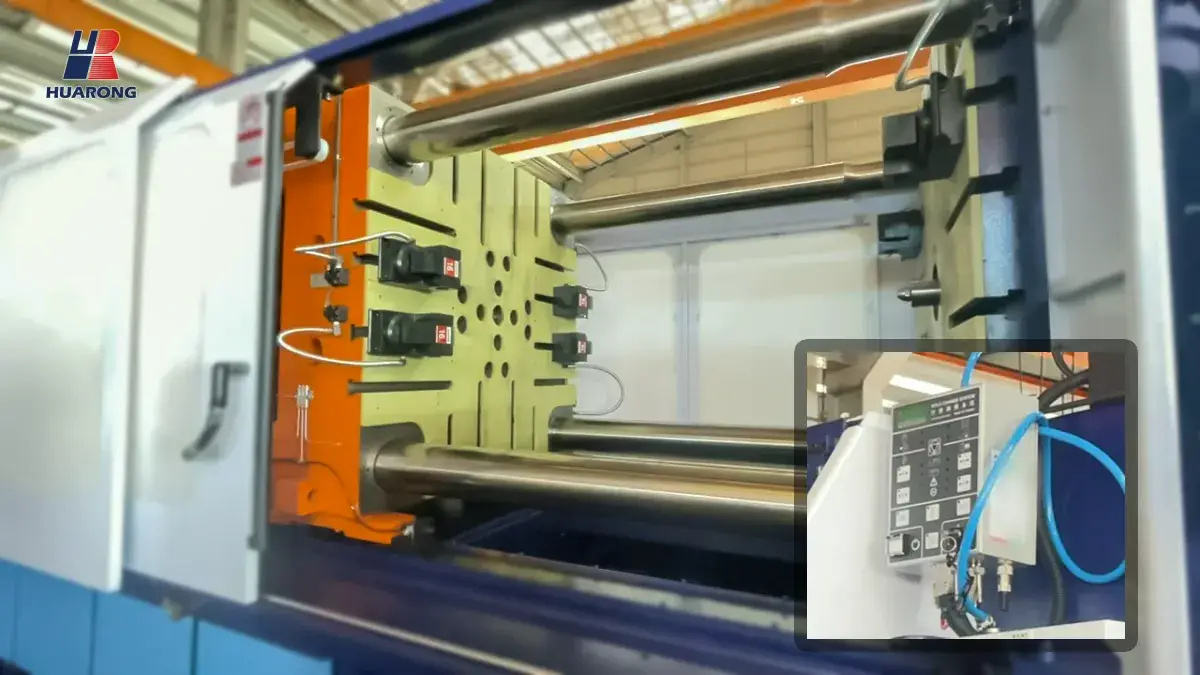

A Quick Mold Change System automates or simplifies the mold changeover process on an injection molding machine. Instead of spending 1–2 hours manually replacing, aligning, and clamping a mold, QMC systems can cut this down to just a few minutes.

- Function: Allows operators to change molds with minimal tools, reduced manual labor, and maximum repeatability.

- Core Components:

- Hydraulic or pneumatic clamping systems: Secure the mold without bolts.

- Magnetic platens: Enable tool-less mold mounting using magnetic force.

- Mold change carts (shuttles): Slide molds in/out for large or heavy tooling.

- Automatic alignment and centering devices: Ensure precise fitting and ejector pin positioning.

- Benefits:

- Reduces downtime and increases productivity

- Enhances operator safety (no climbing into the machine to bolt molds)

- Standardizes setup across machines and operators

Related articles: How to Change a Mold? Mold Change Process for Efficient Mold Loading and Unloading

Successful Story: Quick Mold Change and Stable Operation: A Reliable 24/7 Production Partner

- Injection Molding Business: A Complete Guideline of How to Start

- PET Preform Production Line Planning Guide: From Bottle Buyer to In-House Manufacturing

- Injection Molding Cycle Time: The Key to Faster and Smarter Manufacturing

Not necessarily. A hot runner mold requires a hot runner controller, not a mold temperature controller. However, if the mold base or core requires thermal stability, an MTC may still be recommended, as the benefits of dimensional accuracy and surface finish are important.

Not always. A water tower is sufficient for basic cooling, but when precise and stable cooling is required—especially in high-ambient-temperature environments, a chiller (air- or water-cooled) is recommended to maintain a consistent water temperature.

| Type | Max Temp | Heating Medium | Application |

|---|---|---|---|

| Water-type | ~120°C | Tap or purified water | Packaging, consumer goods, general molding |

| Oil-type | ~300°C | Heat transfer oil | Engineering plastics, automotive, high-gloss parts |

If you are a small workshop, you can choose an air-cooled chiller, which doesn’t require water towers or pipes.

A well-designed injection molding line relies not only on the injection molding machine but also on the intelligent integration of auxiliary equipment. Knowing what each device does—and when to use it—allows you to improve product quality, increase productivity, and lower costs.

At Huarong, we are an experienced injection molding machine manufacturer. We work closely with clients to deliver complete production solutions, including peripheral systems and turnkey automation tailored to your specific needs.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist.., Tainan City 72351, Taiwan

In our next article, we’ll go beyond the basics and explore Advanced Injection Molding Solutions, including:

- Recycling & Reuse Systems

- Special Process Add-ons like Gas-Assisted Molding & Microcellular Foaming