Boost Automotive Parts Output with Smart Injection Molding Machines

2025-06-06 08:43:27

A high-efficiency injection molding machine for automotive parts is the best solution for modern manufacturers facing the challenge of high-mix, low-volume production. By introducing stable-quality injection machines, fast mold change devices, and an integrated smart management system, this customer successfully improved productivity, reduced labor dependency, and maintained consistent product quality, creating an organized, energy-saving, and flexible manufacturing environment.

The customer in this case produces a wide variety of automotive plastic parts and frequently changes molds daily. This makes equipment flexibility and operational efficiency critically important. To meet this challenge, the company introduced multiple servo-driven injection molding machines, all equipped with a quick mold change system and the Huarong Factory Management (HFM) platform, forming a forward-thinking digital manufacturing line.

All machines installed are small to medium-sized servo injection molding machines, featuring high precision, low noise, and energy-saving operation. Even under round-the-clock production shifts, the machines maintain consistent injection pressure and stable product quality.

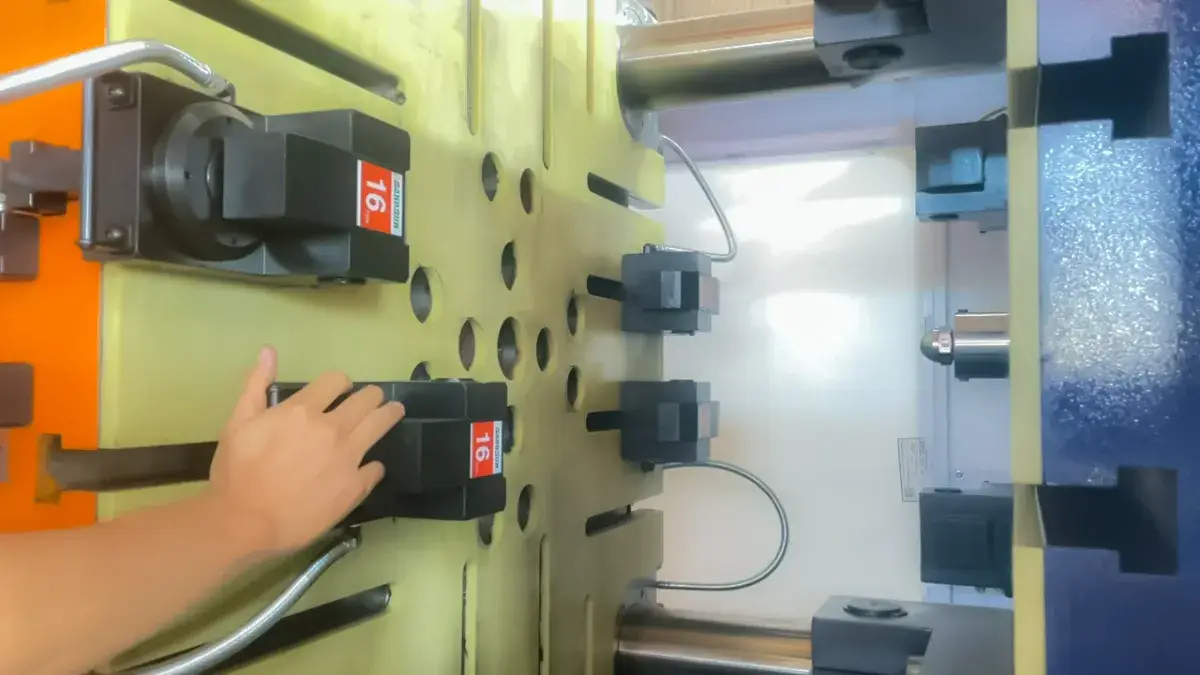

Previously, mold changes required experienced operators, resulting in extended downtime and high operational risks. With the quick mold change devices, a single technician can now dismantle, install, and test molds efficiently. The parameter memory system enables the machine to immediately retrieve and apply historical settings, allowing for a quick transition from mold setup to stable mass production. This shift not only reduces downtime but also minimizes defects and mechanical stress caused by human error.

Automotive plastic components often involve short product life cycles and rapid design updates. The ability to switch molds quickly can significantly reduce machine idle time and improve responsiveness to market demands. Industry studies have shown that traditional mold changes can take 30 to 90 minutes. In contrast, systems equipped with automatic mold clamping, ejector connection, and auto waterline couplers can reduce this time to under 10 minutes, boosting daily output by over 20% in multi-mold operations.

The customer adopted a mirror layout configuration, enabling one operator to manage two machines simultaneously. Combined with a central feeding and drying system, operators only need to monitor cycles, retrieve parts, and perform basic inspections. This layout provides:

- Space-saving and improved production flow

- Reduced labor cost and simplified training

- Higher output per employee and lower human error risk

The symmetrical dual-machine layout also improves visual management, as operators can easily oversee multiple machines from a central position. When combined with HFM visual dashboards, line leaders can make faster decisions on intervention and batch scheduling.

Related article: Huarong Group's mirror injection molding machine improves efficiency

Regarding the automation system, the customer clarified that due to the large number of mold types and product variations, adopting manipulator robots would necessitate frequent jig changes and path adjustments, making manual dual-machine operation the most flexible solution for their current needs.

The customer implemented the Huarong Factory Management (HFM) platform to centralize machine and production data, giving the management team full real-time control. Key benefits include:

- Live monitoring of output, cycle time, yield rate, and alarms for each machine

- Centralized data storage for traceability and quality analysis

- Remote login function for off-site monitoring and control

Related product: Smart Factory Management-HFM System

Each mold has its injection parameter recipe stored in the HFM system. Once the mold is changed, the operator can apply the optimized settings with a single click. This drastically shortens trial time and reduces defect rates, achieving a seamless transition from mold change to stable production.

What impressed us most was the customer’s future-ready mindset. From the initial construction phase, they incorporated high-spec setups, including network wiring, IP configurations, uninterruptible power supplies, and power outlets, all aligned with HFM system requirements. The factory floor is brightly lit, clearly laid out, and well-organized, reflecting a high level of manufacturing discipline and forward-looking smart factory planning.

The customer expressed strong satisfaction with the overall performance of Huarong’s injection molding machines, especially in the following aspects:

- Stable injection pressure and speed, minimizing weight variation

- Uniform barrel heating to prevent cold spots or bubbles

- Repeatable cycle times, ideal for long runs and precision parts

Through equipment stability and systematic parameter control, the following issues were significantly reduced:

- Short shots and flashing: resolved via optimized flow and pressure

- Flow marks and bubbles: prevented through better degassing and thermal control

- Warpage and sink mark: mitigated with mold temperature tuning and holding profile adjustment

Further reading: Short Shot in Injection Molding: Causes, Detection & Solutions

Energy consumption accounts for 50–70% of the total operating cost of an injection molding machine, with rising electricity rates and increasing pressure from automakers on sustainability.

Compared to traditional hydraulic machines, servo injection machines offer:

- Auto-idle mode during non-operation, reducing power waste

- Stable thermal control, lowering cooling water consumption

- According to the customer’s real production data, energy savings range from 30% to 60%

Related feature: Servo system

The customer’s bright layout placed two injection machines in front-and-back pairs, enabling one person to manage two machines simultaneously. This saves labor, maximizes space utilization, and sets a new benchmark for efficient production site management. This symmetrical dual-machine layout also improves visual management, as operators can easily oversee multiple machines from a central position.

This case fully demonstrates the value of a high-efficiency injection molding machine — not just in terms of equipment, but as a total solution that includes smart management, intelligent layout, optimized labor, and energy-saving efficiency. With quick mold change, HFM integration, and stable machine performance, the customer built a logical, organized, and flexible production environment.

As more factories embrace modular automation, data-driven control, and smart equipment, early adopters like this customer position themselves ahead of industry shifts. By combining people, process, and platform, they’ve built a future-ready production model aligned with both lean manufacturing and digital transformation goals.

At Huarong, we don’t just deliver machines — we help you build a fully integrated injection molding solution tailored to your production needs. From planning to implementation, from trial to mass production, from operation to factory-wide management, we are your best partner on the journey to smart manufacturing and sustainable competitiveness.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/