Maintenance-Friendly Design Features in Vertical Injection Molding Machines

2026-01-22 08:45:15

Vertical injection molding machines serve as production-critical assets in manufacturing environments where uptime and consistency determine profitability. While maintenance procedures address equipment care after installation, machine design determines how reliably equipment performs over years of continuous operation.

This article focuses on maintenance from a machine design perspective, reviewing maintenance-friendly design features commonly expected in vertical injection molding and explaining why they matter for stable, long-term operation.

Maintenance-friendly design refers to how machine architecture, component integration, and structural layout reduce wear accumulation and prevent performance drift over extended production cycles. In vertical injection molding, these considerations are especially critical due to frequent use in insert molding, overmolding, and precision assembly applications.

This concept is not about maintenance schedules or servicing routines. It is about design choices that reduce how often maintenance becomes necessary, and how predictable long-term performance remains under real production loads.

High-volume manufacturing environments cannot afford frequent production stoppages. Insert molding operations, where metal components are positioned before each cycle, require machines that maintain positioning accuracy across millions of cycles without drift.

Manufacturers increasingly evaluate equipment based on design durability rather than service accessibility alone. Maintenance-friendly design supports production by:

- Reducing mechanical stress accumulation during repeated operation

- Supporting operational visibility for early problem detection

- Minimizing unexpected failures through robust construction

Vertical injection molding machines, with their simplified motion profiles and compact structure, align well with these production requirements.

The vertical orientation of injection molding machines offers clear structural advantages. Gravitational forces align directly with the clamping direction, allowing injection pressures to be managed through compression rather than complex load paths.

Compared to horizontal systems, vertical machines operate with fewer moving axes. The injection unit follows a controlled, linear motion while the mold area remains stable during injection, reducing the number of mechanical interfaces exposed to wear. This structural simplicity supports long production runs by minimizing stress accumulation and maintaining consistent force distribution.

Open mold access characterizes vertical injection molding machine design. The vertical platen arrangement allows operators to view the mold face directly during setup and production, supporting faster visual inspections without production interruption.

This accessibility becomes critical in insert molding and overmolding environments where operators position components before each cycle. Improved accessibility allows operators to:

- Visually confirm the mold condition and insert positioning during production

- Identify potential issues early in the production cycle

- Perform inspections without extended machine stoppages

Modern vertical injection molding machines incorporate a modular construction philosophy in key systems. Injection, clamping, and power unitsare discrete assemblies that interface with the machine frame through standardized connection points.

This modular approach offers practical advantages:

- Individual components can be accessed or replaced without extensive disassembly

- Machine downtime is reduced when adjustments or replacements are required

- Future upgrades or configuration changes can be implemented more efficiently

Modularity also supports application flexibility, because injection unit specifications can be selected according to shot size, plasticizing stability, and precision requirements without changing the entire machine concept.

Precise clamping alignment protects both molds and machine components from premature wear. Vertical machines achieve this through platen parallelism that remains stable under repeated clamping force application.

The clamping system distributes tonnage evenly across the mold face. When design engineers optimize platen geometry and guide systems, clamping force remains uniform across thousands of production cycles.

Consistent clamping helps:

- Maintain mold alignment during repeated cycles

- Reduce uneven stress on expensive tooling investments

- Support the dimensional stability of molded parts throughout production runs

By protecting both the mold and the machine structure, a stable clamping system contributes directly to long-term production reliability.

The power unit is a primary source of long-term stability in vertical injection molding machines because it determines how force, pressure, and motion are generated and controlled throughout each cycle. When power units are designed as modular assemblies, they can be structurally isolated from vibration-prone components and integrated with the machine frame through standardized mounting points.

This modular approach helps reduce stress transfer to the clamping and injection systems, which in turn lowers cumulative mechanical fatigue over long production periods. Stable power delivery also improves consistency in injection pressure, clamping force buildup, and cycle repeatability, especially in insert molding applications where small variations can accumulate into quality issues.

Control system architecture functions as a preventive design rather than a reactive diagnostic. Modern vertical injection molding machines incorporate sensors throughout hydraulic, electrical, and mechanical systems that monitor performance parameters continuously.

These integrated controls track temperature stability, pressure consistency, and cycle timing variations. Rather than focusing on corrective actions after problems occur, these systems help:

- Maintain consistent cycle conditions across extended production runs

- Detect abnormal operating trends at an early stage

- Alert operators before deviations affect part quality or cause component stress

By providing real-time operational data, integrated systems support proactive adjustments rather than reactive repairs.

Automation-ready design reduces manual handling requirements, which can introduce variability and operator dependency. Vertical machines accommodate robotic part removal, automated insert feeding, and conveyor integration through standardized interface provisions.

The vertical format simplifies automation system integration. Robots access the mold area from above or from the sides without interfering with the injection unit movement, and the open mold configuration allows vision systems to verify part quality during production.

Automation-ready configurations contribute to:

- Consistent cycle timing without manual intervention

- Reduced handling-related disturbances that cause mechanical stress

- Improved repeatability across long production runs

Compatibility with automated material handling reduces operator dependency while supporting consistent output. When machines are designed with automation interfaces from initial engineering phases, manufacturers can implement progressive automation as production volumes scale.

Maintenance-friendly design in vertical injection molding machines is the result of deliberate engineering choices focused on stability, accessibility, and structural efficiency. Features such as compact vertical layout, accessible mold areas, modular construction, stable clamping systems, and integrated control platforms work together to support consistent production and reduced operational interruptions.

By addressing maintenance challenges at the design level rather than through intensive servicing requirements, vertical injection molding machines provide manufacturers with equipment that delivers the uptime and consistency required by modern manufacturing operations.

If you are evaluating a vertical injection molding machine for insert molding or precision applications, share your part requirements with Huarong. Our team can recommend a suitable configuration based on your production goals and automation plan.

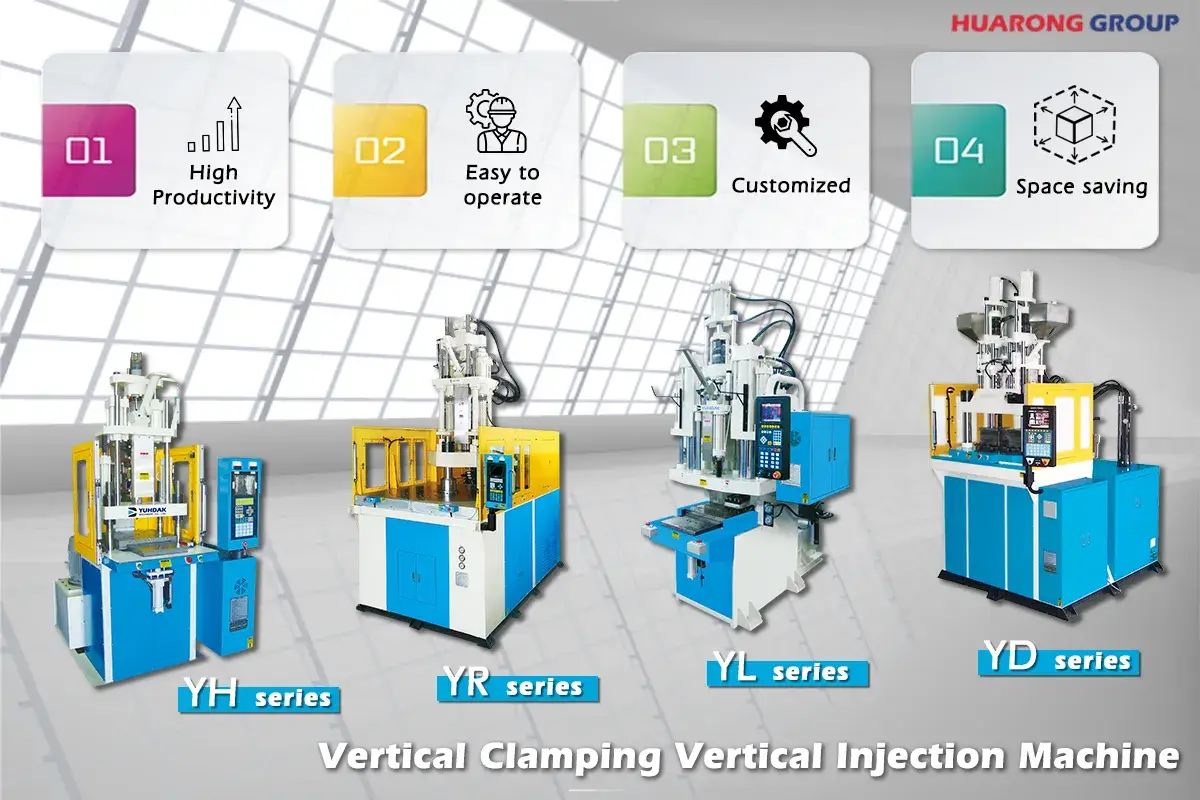

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/