Gas Assisted Injection Molding: Process, Mold Design, Defects, and Alternatives

2026-01-16 09:55:52

Many teams search for “gas-assisted injection molding” when thick sections create sink marks, weight targets are tight, or conventional packing becomes limited once the gate freezes. GAIM addresses these challenges by injecting nitrogen into the still-molten polymer within the mold cavity, creating an internal pressurized gas channel that supports packing during cooling and helps the surface skin solidify against the cavity wall.

GAIM is NOT the same as microcellular injection molding. GAIM forms hollow channels by injecting gas into the cavity after partial filling. Microcellular injection molding introduces a supercritical fluid, typically N₂ or CO₂, into the melt to create a polymer gas solution that nucleates microcells after the pressure drop in the mold.

In this article, we cover the GAIM process step by step and provide a clear comparison with microcellular injection molding to help select the right technology for your part and production goals.

Gas Assisted Injection Molding (GAIM), also known as gas injection molding, is a process where molten plastic is injected into a mold cavity (typically to a short-shot percentage), and then high-pressure nitrogen gas is injected into the polymer melt through a gas pin or nozzle. The gas displaces molten material in the core region, creating a hollow channel, while simultaneously acting like an internal packing force to compensate for volumetric shrinkage.

GAIM is primarily adopted to:

- Reduce sink marks in thick sections (handles, ribs, bosses, structural beams)

- Reduce part weight by hollowing the core

- Reduce holding pressure and sometimes required clamping force

- Improve dimensional stability in specific thick-wall geometries

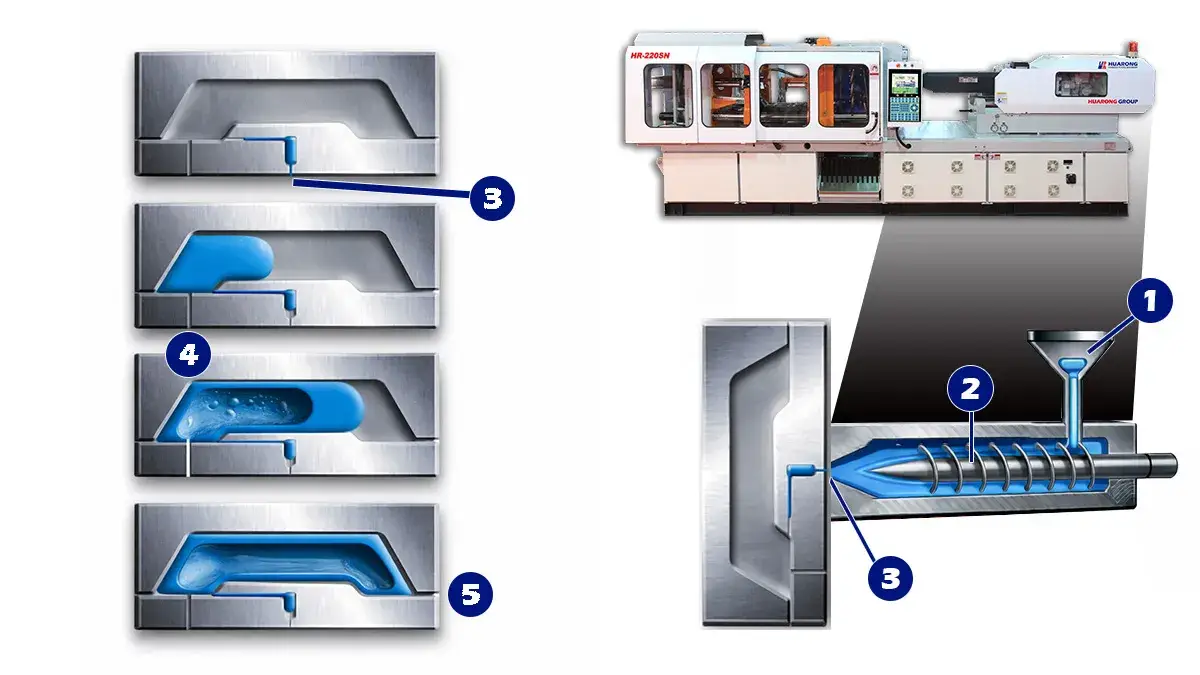

Plastic pellets [1] are fed from a hopper into a rotating screw [2]. As the screw rotates, its helical flights convey the pellets forward while shear and barrel heat melt them into a homogeneous polymer melt. The screw then advances axially under an applied force, injecting the melt through the nozzle and runner system into the mold cavity [3].

After the cavity is filled to a predetermined percentage, melt injection is stopped (or reduced to a controlled switchover point). Pressurized inert gas is then introduced through the gas inlet [4] according to the defined delay time and pressure profile.

The gas preferentially travels through the hottest and least viscous region, typically the center of the melt flow. As it advances, it displaces the molten core material, pushing the polymer outward toward the cavity walls. This forms a hollow channel while maintaining internal holding pressure to counteract shrinkage during cooling.

By designing and positioning the gas outlet or overflow location [5], the hollow core can be directed and stabilized to a significant extent. This helps control where the displaced melt flows, where the cavity forms, and how consistent the channel geometry remains across production.

In gas assisted injection molding, two main approaches are commonly used depending on whether the goal is to create internal hollow channels or to improve surface definition.

The first approach is internal gas injection, in which nitrogen is injected into the molten polymer within the component cavity to form a hollow core and maintain holding pressure from within. This is the most widely used method in GAIM because the gas follows the hottest, least viscous flow path, creating predictable hollow sections when the part design supports a continuous thick region.

The second approach is external gas injection, where gas is applied to the outside surface of the component, still within the mold cavity, to consolidate the part against the mold surface. In this approach, the gas is introduced as a very thin layer between the mold core and the back surface of the part, helping the show surface more closely replicate the mold definition as the resin cools.

GAIM is a system solution. The mold and the gas control system determine repeatability.

- Nitrogen source and gas generation or supply

- Injection molding machine

- Gas pressure control unit for injection pressure, holding pressure, timing, and safety logic

- Gas injection interface (gas pins, gas nozzles, or integrated hot runner solutions)

- Mold sealing and gas routing to keep gas where it is intended to go and to manage venting

- Channel predictability is a geometry problem first

If the gas cannot find a consistent path, results can drift, leading to uneven gas flow, incomplete filling, or localized weak spots. - Gate strategy must support the intended gas path

In simple terms, normal packing stops working once the gate freezes because no more plastic can flow in to make up for shrinkage, but gas packing can still keep applying pressure through the gas channel even after the gate is closed. For this reason, the gate position and the flow direction should be designed so that the thick area, which is most likely to show sink marks, stays connected to a steady gas path until the surface layer becomes firm. This way, pressure can continue to support the thick section at the right time, reducing the chance of sink formation. - Cooling balance prevents warpage even when the sink is solved

Gas packing can transfer pressure more efficiently through the part, so you can often achieve the needed shrinkage compensation with less internal stress, which helps reduce warping and dimensional drift after molding. However, this advantage is strongest only when the part cools evenly: if one side or one region freezes much earlier than another, the part will still shrink by different amounts in different areas, and those uneven shrinkage forces can still cause warpage even if gas packing is used. - Plan for venting and controlled gas release

When the mold opens, gas escapes through the air gap, which must be treated as a managed medium rather than an afterthought.

GAIM works best when the product design allows a stable hollow channel and when the thick section is intentional and functional.

Common GAIM categories include:

- Handles and grip-like structures

- Frames and beams where stiffness is needed but weight should be reduced

- Thick rib networks where sink must be controlled, but a hollow core is acceptable

Below are the defects frequently discussed in GAIM engineering, along with the process knobs that typically influence them.

Blow through is when gas breaches the surface, often leaving a rupture, whitening, or a visible surface defect. Industry references commonly describe blow-through as a risk when pressure or timing are not controlled.

What we check first:

- Gas delay time and skin formation window

- Peak gas pressure and ramp profile

- Wall thickness near the gas path

- Short shot ratio and whether the cavity is overfilled before gas injection

Gas fingering is an unstable gas front that branches away from the intended channel and reduces stiffness and repeatability. This behavior is widely described as a common GAIM issue.

What we check first:

- Whether the geometry forces the gas to split into competing paths

- Whether delay time and melt temperature create a melt core that is too mobile

- Whether the short shot ratio leaves too much open volume for gas to search

This can happen if the short-shot percentage is too low or if the gas pressure hold is insufficient to complete the fill consistently.

What we check first:

- Fill percentage and injection velocity profile

- Gas holding time and pressure stability

- Venting and air trap locations

Although both use gas, their outcomes are fundamentally different.

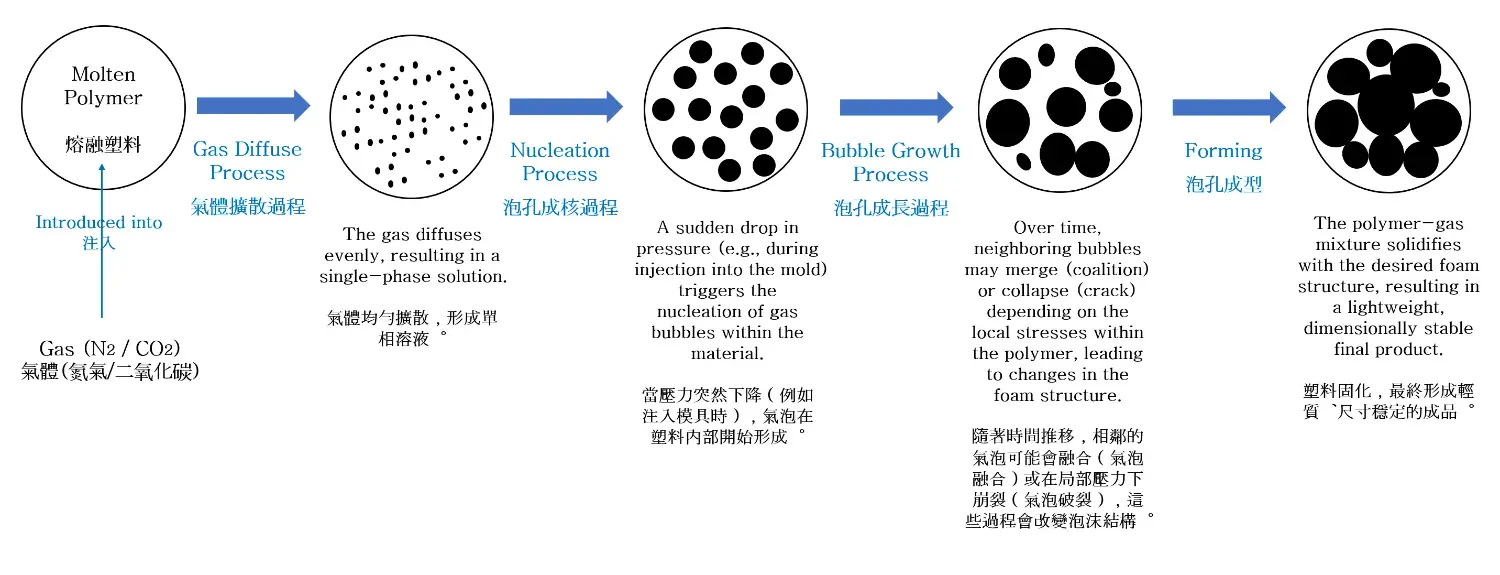

Microcellular injection molding is a physical foaming process that incorporates supercritical gas, typically nitrogen or carbon dioxide, into molten polymer during injection molding. The gas dissolves under pressure, then micro scale bubbles nucleate when the mixture experiences a pressure drop in the mold.

Further reading: Microcellular Foam Injection Molding: A Complete Guide to Lightweight and Energy-Efficient Production

- Structural difference

- GAIM: single hollow channels

- Microcellular: distributed micro-cell foam structure

- Gas introduction

- GAIM: gas injected after partial filling

- Microcellular: gas dissolved before injection

- Application focus

- GAIM: localized thick sections

- Microcellular: global weight and shrink control

GAIM is ideal when:

- The product has a dominant thick section or frame path suitable for a hollow channel

- A hollow channel is mechanically acceptable and does not compromise sealing or fastener integrity

- The business case values sink reduction and weight reduction in that thick path

- The mold can incorporate gas pins, seals, and controlled venting

Microcellular Injection Molding is ideal when:

- Broad, uniform weight reduction is required

- Shrink and warpage must be controlled across complex geometry

- Multiple thick regions exist without a continuous gas path

- A scalable process is needed across many part designs

To reduce sink marks and internal stress in thick sections while reducing weight by forming hollow channels and maintaining internal holding pressure during cooling.

No. GAIM creates hollow channels; microcellular molding creates a fine foam structure throughout the part.

Many thermoplastics can be used, but trials are required to confirm skin stability and flow behavior.

Microcellular can be more geometry tolerant when a stable GAIM channel is difficult, and it supports broad lightweighting and shrink control through microcell nucleation mechanisms rather than a single hollow channel path.

Interest in Gas Assisted Injection Molding usually reflects a need to reduce sink, weight, or holding pressure in thick sections. GAIM is highly effective when the part geometry supports a predictable hollow channel. However, for many modern designs with complex shapes and multiple thick regions, Microcellular Injection Molding offers a more scalable and robust solution.

Send us your part file and requirements, and we’ll recommend the best process and next steps.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/