Co Injection Molding: A Complete Technical Guide for Modern Plastics Manufacturing

2025-11-21 13:06:52

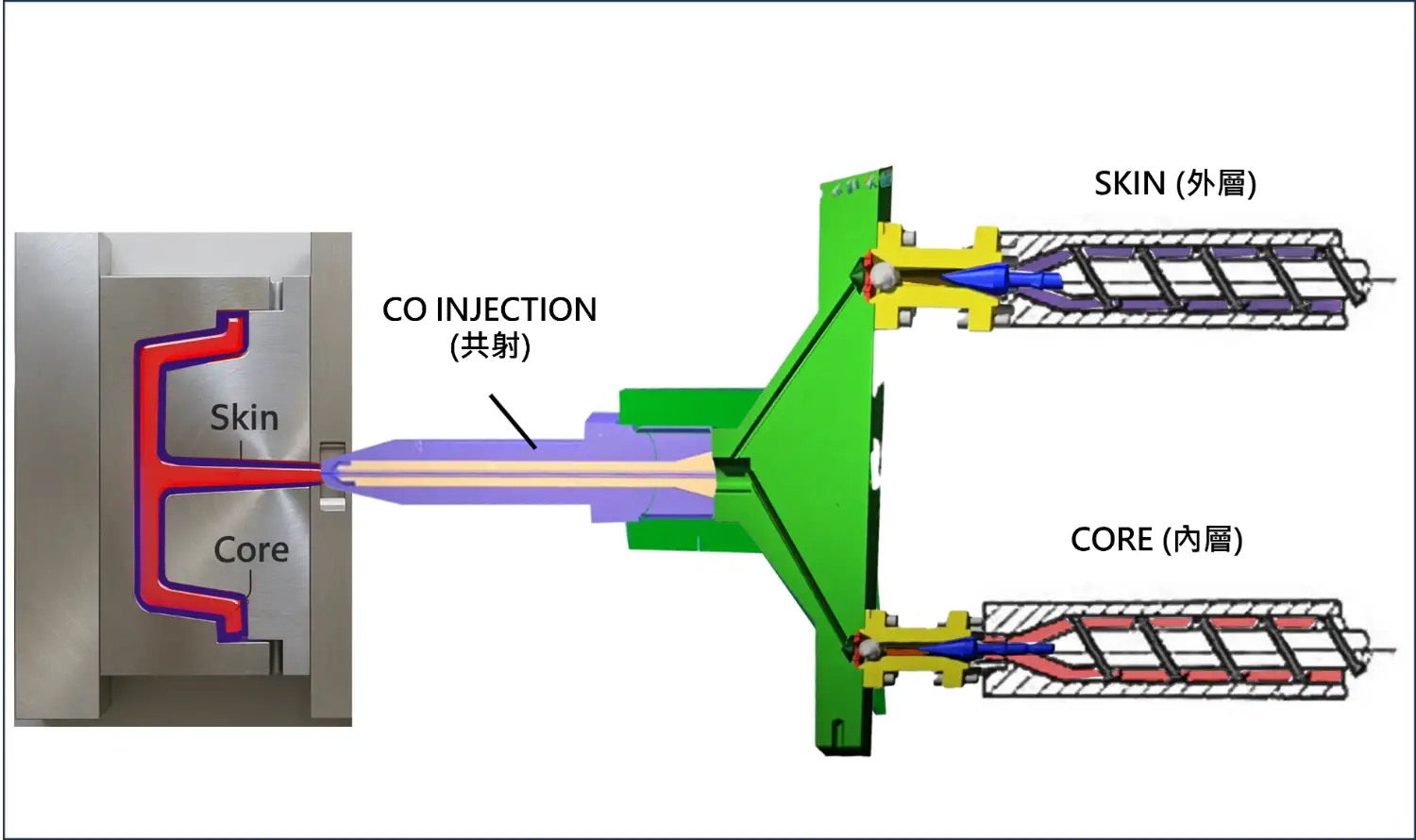

Co-injection molding is a specialized multi-material injection process that produces parts with a skin-core structure in a single shot. Instead of shaping a part from a single homogeneous polymer, we design a “sandwich” with a high-quality outer skin and a functional inner core. This enables combinations like barrier layers, recycled cores, foamed interiors, and tailored mechanical properties, making co-injection molding a crucial technology for packaging, automotive, consumer goods, and circular economy applications. In this guide, we will explain the fundamentals, process parameters, mold design, common defects, and real-world applications from an engineering perspective.

Co injection molding belongs to the broader family of sandwich molding technologies where at least two melts are injected to build a layered structure through the wall thickness. Rather than adding material zones on the outside (like overmolding), we control how different melts occupy the cross-section of a part. This is especially powerful when we want a barrier layer or to hide a recycled core behind a cosmetic surface.

In a standard co injection molding process, two polymer melts are injected sequentially into the same cavity:

- The skin material is injected first and flows along the cavity walls, forming the outer layer.

- Before the cavity is fully packed, the core material is injected and displaces the skin melt in the center of the flow channel.

- Optionally, a short final skin shot can encapsulate the core completely at the gate.

The result is a skin-core (or skin-core-skin) structure, often called a sandwich molding, where the visible surfaces are entirely skin while the core determines much of the mechanical and barrier performance.

Conventional injection molding uses a single melt; mechanical and visual properties are determined solely by the geometry and a single material. Overmolding or two-shot molding builds multiple materials in different regions of the part's geometry (e.g., hard substrate plus soft TPE grip). Co injection molding instead manipulates layer distribution inside the wall while keeping the geometry mono-piece.

This distinction is important for applications such as barrier packaging, where the internal structure might be PP/EVOH/PP but the consumer sees only PP, or for structural components with a lightweight core and robust surface.

Further reading: What Is Overmolding? Process, Applications, and Key Differences from Insert Molding

Several terms appear frequently in co injection molding discussions:

- Skin / Core: Primary outer and inner materials.

- Barrier layer: A core (or intermediate) layer optimized for gas, aroma or moisture barrier.

- Core penetration: How far core material advances through the flow path.

- Core breakthrough: Defect where core reaches the surface and becomes visible.

- CSC structure (core-skin-core): A special morphology where a new skin layer forms again at the wall due to complex interface dynamics.

The performance of co injection molding is governed by the interaction between machine control, melt rheology and cavity geometry. The process sequence is simple on paper, but in production, small deviations in injection pressure, melt temperature or switchover timing can dramatically change layer distribution and create defects.

A representative sequential co injection cycle follows these steps:

1. Plasticizing

Each injection unit (skin and core) plasticizes its material with individually set melt temperatures, back pressure and screw speeds.

2. Skin injection (Phase 1)

The skin unit injects first, pushing melt into the cavity and forming a continuous layer along the cavity surfaces, especially near the walls and

gate.

3. Core injection (Phase 2)

At a pre-defined stroke position, volume, or cavity pressure, the machine switches to the core unit. The core melt penetrates the center of

the flow channel, displacing the skin toward the walls.

4. Skin sealing (Phase 3 – optional)

A short skin shot at the end can “seal” the gate and visible areas, ensuring the core remains fully encapsulated.

5. Packing and holding

Holding pressure—often via the skin unit—compensates shrinkage, stabilizes dimensions and helps control the final skin thickness.

6. Cooling and ejection

After sufficient cooling, the part is ejected and the next cycle begins.

Co injection molding is extremely sensitive to injection pressure and melt temperature because they determine flow front velocity, viscosity and interface stability:

- Higher injection pressure and injection speed accelerate the flow front and can increase core penetration length, but they also raise the risk of core breakthrough if the skin becomes too thin or stretched.

- Melt temperature differences between skin and core change viscosity ratios. A hotter, lower-viscosity core can more easily push through the skin and reach the surface if not controlled.

- Back pressure during plasticizing affects melt homogeneity and temperature profile, indirectly influencing how the skin and core interact during filling.

Once filling is complete, packing and holding determine how the skin and core shrink together and how thickness distribution freezes in:

- Insufficient holding pressure can cause sinks and voids in the core region; excessive holding can distort the interface or induce residual stresses.

- Packing time must be long enough until the gate freezes; in co injection molding, this often correlates with the skin’s local solidification at the gate.

- Cooling efficiency controls cycle time and warpage. Uneven cooling can warp the skin-core structure, causing local thinning or thickening of the skin layer.

Successful co injection molding starts with well-chosen injection molding materialpairs that are compatible in terms of processing window, adhesion and recyclability. Material rheology strongly influences skin/core morphology and barrier layer stability.

Typical combinations include:

- Packaging: PP or PET skin with EVOH or PA barrier layer in the core to reduce oxygen or CO₂ permeability.

- Recycling: Virgin PP skin with PCR PP or mixed recyclate core, providing a clean appearance and controlled mechanical properties while consuming low-cost material.

- Structural parts: Tough, impact-resistant skin over a glass-filled or foamed core for stiffness and weight reduction.

Adhesion between layers can be driven by chemical compatibility (e.g., PP/PP) or by tie-layer/compatibilizer use where we combine polymers from different families.

For barrier packaging, the barrier layer must be continuous and properly located within the wall:

- Too close to the inner surface and it may be removed during trimming or wear.

- Too close to the outer surface and it may become visible or interfere with decoration or regulatory requirements.

At the same time, the industry is moving toward recyclable co injection structures, such as PP/EVOH/PP containers designed so that the small EVOH fraction does not significantly disrupt PP recycling streams.

Because we are managing multiple melt fronts, co injection molding introduces failure modes not seen in single-material molding.

Core breakthrough occurs when the core material overtakes the skin melt front and reaches the part surface. Symptoms include streaks, islands of core color in the skin or exposed recyclate at visible surfaces.

Key root causes:

- Excessive core injection pressure or injection speed.

- Skin shot volume too small or switchover too early.

- Large viscosity contrast (too low core viscosity vs skin).

Engineering solutions typically involve:

- Increasing skin volume and/or delaying core start.

- Reducing core injection pressure or ramping it more gradually.

- Adjusting melt temperatures to narrow the viscosity gap.

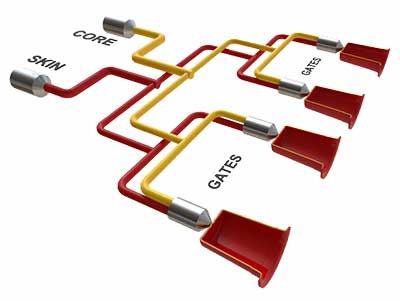

In multi-cavity tools with bifurcated runners, inter-cavity core penetration imbalance is common. Some cavities may show deep core penetration while others barely receive core material at all.

Mitigation measures include:

- Rebalancing the runner system and valve gate timings.

- Adjusting total injection pressure and core flow rate.

- Using simulation to optimize the skin-to-core ratio and flow conditions before steel corrections.

Poor interface bonding can lead to delamination under stress or impact, particularly when the part flexes. Contributing factors include:

- Low interfacial temperature between skin and core.

- Material incompatibility or contamination at the interface.

- Excessive shear that degrades one of the materials.

Weld lines (especially in ribs or knit-line regions) may become more noticeable when skin thickness varies due to local core penetration differences.

Because skin and core may have different shrinkage and modulus, non-uniform layer distribution leads to warpage and performance scatter:

- The part may bend toward the side with a thicker or stiffer layer.

- Mechanical test results (e.g., tensile or impact) can vary significantly across samples if process control is weak.

Co injection molding has moved from a niche technology to an industrial standard in several sectors. Beyond material savings, it offers strategic advantages in product performance and sustainability when combined with smart cell design and cycle time optimization.

One of the most mature applications is high-barrier packaging:

- PP or PET containers and preforms with an EVOH or PA barrier layer in the core extend shelf life for oxygen-sensitive foods and beverages.

- Co injection can integrate barrier functionality without secondary coatings, laminates or complex assembly.

For structural components, co injection molding enables sandwich parts with:

- Compact, durable skins.

- Foamed or filled cores for weight reduction and stiffness.

Automotive interior panels, appliance housings and industrial covers can thus meet crash, noise and vibration requirements while reducing material consumption. Integrating microcellular foam in the core is especially attractive for lightweighting strategies.

Co injection molding is a powerful tool for circular economy because it allows:

- High percentages of post-consumer recyclate to be hidden in the core while maintaining a clean virgin skin.

- Mono-material concepts (e.g., PP/PP) that remain compatible with established recycling streams.

co injection molding is a multi-material process creating a skin-core structure in one shot, with a high-quality skin on the outside and a different core inside. It's used for barrier layers (e.g., EVOH), high recycled content, weight reduction, or achieving specific stiffness, impact strength, and surface quality that a single material can't provide.

Typical defects include surface core breakthroughs, cavity layer imbalance, skin-core delamination, and warpage from uneven shrinkage. Troubleshooting involves:

- Increasing skin shot volume or delaying core start to prevent breakthrough.

- Adjusting injection pressure and valve gating to rebalance core penetration between cavities.

- Raising interface temperature or using more compatible materials to improve adhesion.

- Optimizing cooling and packing profiles to reduce residual stress and warpage.

We select skin and core materials based on processing compatibility, adhesion, regulatory standards, and recyclability. The skin is usually virgin or high-performance with good appearance, UV resistance, or food-contact approval. The core may be barrier polymer, recycled material, foamed, or glass-filled. Checks include melt temperature overlap, manageable viscosity ratios, and good interface adhesion through compatibility or tie layers.

CO injection molding combines barrier performance, recycled content, lightweight design, and high surface quality in one part. As Huarong, a Taiwan-based injection molding machine manufacturer, we work with customers to meet real factory constraints.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan