Thin Wall Injection Molding: Key Technology for Efficient and Lightweight Manufacturing

2025-11-13 13:04:27

Thin wall injection molding is a high-performance injection molding process developed to manufacture plastic parts with extremely thin, uniform walls while maintaining mechanical strength, dimensional accuracy, and high production efficiency. Unlike conventional molding, thin wall injection molding operates within a narrow processing window. It requires precise control of injection pressure, injection speed, material viscosity, mold temperature, and cooling efficiency. When properly engineered, it delivers significant cost savings, productivity gains, and environmental benefits.

Thin wall injection molding refers to the production of plastic components with wall thicknesses typically below 1.0 mm. In most industrial applications, thin wall thickness commonly falls within the range of 0.4–0.8 mm, while ultra-thin packaging and medical disposable components may reach 0.1–0.3 mm under highly specialized conditions.

More critical than absolute thickness is the flow length ratio (FLR)—the ratio of flow length to wall thickness—which commonly exceeds 150:1 and may reach 300:1 in advanced thin wall designs. At such ratios, melt flow behavior becomes extremely sensitive to temperature loss, pressure drop, and gate freeze-off timing.

- Weight Reduction and Cost Savings:

Reduced wall thickness directly lowers raw material consumption, transportation weight, and packaging costs, making thin wall molding highly attractive for cost-sensitive, high-volume industries. - High Production Efficiency:

Thin walls solidify faster, enabling 30–50% reductions in cycle time compared with conventional injection molding when cooling is properly balanced. - Design Freedom for Complex Geometry:

Thin wall injection molding enables compact designs, fine details, and complex geometries without sacrificing structural integrity when ribs and flow paths are engineered correctly. - Environmental and Sustainability Benefits:

Lower material usage, reduced cycle time, and improved energy efficiency collectively reduce carbon footprint per molded part.

Successful thin wall injection molding begins with correct part design. Poor design choices amplify defects such as short shots, warpage, sink marks, flash, and weak weld lines.

Uniform wall thickness is the most critical design principle. Sudden thickness transitions cause uneven mold filling behavior and differential cooling.

- Recommended minimum wall thickness: ≈ 0.9 mm (depending on material)

- Avoid abrupt thickness changes

- Use ribs or stiffeners instead of thick sections

- Ensure smooth flow paths to prevent premature freeze-off

Ribs improve stiffness but must be carefully proportioned to avoid sink marks and flow hesitation.

- Rib thickness ≤ 50–60% of nominal wall thickness

- Rib spacing ≥ 3× wall thickness

- Rib root radius < 0.5× wall thickness

- Draft angle ≥ 1° for reliable demolding

Cross ribs or gussets may be added to improve structural rigidity without increasing wall thickness.

Sharp corners disrupt melt flow and concentrate stress.

- Rounded internal and external corners improve mold filling behavior

- Larger radii reduce pressure loss and warpage

- Adequate draft angles support clean ejection at high speeds

Thin wall parts require extremely fast cavity filling, making gate design critical.

- Gate thickness should be equal to or larger than wall thickness

- Hot runner systems are strongly recommended

- Edge gates or valve gates provide stable high-speed flow

- Gate wells reduce shear stress and prevent localized defects

Further reading: Common Injection Molding Defects: Causes, Types, and Solutions

Thin wall injection molding demands materials with low viscosity, strong shear-thinning behavior, and thermal stability under high injection speed and pressure.

| Material | Flowability | Typical Applications | Engineering Notes |

|---|---|---|---|

| PP | High | Packaging, automotive | High-flow grades require shrinkage control |

| HDPE | High | Food containers | Avoid degradation under high shear |

| LDPE | High | Packaging | Precise temperature control needed |

| PA | Medium–Low | Precision parts | Hygroscopic, requires thorough drying |

| PC | Low | Optical components | Difficult for extreme thin walls |

| LSR | High | Medical devices | Flash-prone, requires precision tooling |

Material viscosity consistency is essential. Small variations in melt flow index can cause unstable injection pressure and filling imbalance.

Further reading: Understanding the 10 Most Common Injection Molding Materials

Thin wall injection molding is a injection pressure- and injection speed-dominated process. Stable production requires disciplined process control.

- Material Heating and Plasticizing:

Material is plasticized uniformly to ensure consistent viscosity. - High-Speed Injection:

Ultra-fast injection prevents premature solidification and ensures complete cavity filling. - Packing and Holding:

Very short, pressure-stable holding phase before gate freeze-off. - Cooling and Solidification:

Efficient and uniform cooling minimizes warpage and internal stress. - Demolding and Trimming:

Proper draft angles and ejector design ensure clean part release.

Rotational molding, vacuum forming, and thermoforming can produce thin sections, but they lack the precision, strength, and repeatability of thin wall injection molding for structural parts.

- Regular mold cleaning and vent inspection

- Monitoring injection pressure, speed, and temperature stability

- Operator training focused on thin wall behavior

- Periodic calibration of cooling and clamping systems

| Defect | Root Cause | Engineering Countermeasure |

|---|---|---|

| Short Shot | Premature freeze-off | Increase injection speed and injection pressure |

| Warpage | Uneven cooling | Optimize cooling efficiency and mold temperature balance |

| Sink Marks | Non-uniform thickness | Maintain consistent wall design, optimize ribs |

| Flash | Mold deflection | Improve clamping force and platen rigidity |

| Weak Weld Lines | Unbalanced flow | Improve gate location and flow symmetry |

| Dimensional Deviation | Poor tolerance control | Validate mold and conduct process capability studies |

Thin wall injection molding is widely used in industries requiring lightweight, high-volume, and high-precision plastic components.

- Medical Devices

Syringes, diagnostic cartridges, and disposable medical components with wall thickness as low as 0.1–0.3 mm. - Consumer Electronics

Mobile phones, laptops, and camera housings requiring lightweight yet rigid enclosures. - Automotive Components

Interior trims, covers, and housings contributing to vehicle weight reduction and fuel efficiency. - Food Packaging

Containers, cups, lids, and sterile packaging optimized for logistics and sustainability.

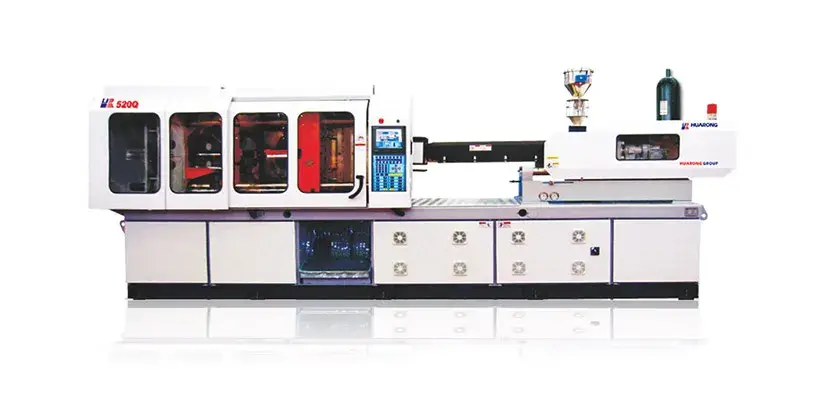

Huarong’s HR-Q Accumulator-Assisted Injection Molding Series is engineered specifically for thin wall injection molding applications requiring extreme injection speed, high injection pressure, and long-term mechanical stability.

- High-Speed Precision Injection

Servo-controlled accumulator system delivers rapid oil discharge for ultra-fast filling and stable pressure control. - Reinforced Structural Design

Enlarged tie bars and thickened platens with advanced stress analysis improve structural durability by over 20%. - High-Response Injection Unit

Rigid, wear-resistant injection components ensure consistent performance under continuous high-speed operation. - Servo Valve + Accumulator System

Combines instantaneous response with high-pressure stability, significantly improving repeatability in thin wall molding.

Suggested machine: HR-Q Accumulator-assisted Injection Machine

Thin wall injection molding is a cornerstone technology for modern plastics manufacturing, enabling lightweight design, material efficiency, and high-speed mass production. Although technically demanding, it delivers exceptional advantages when supported by proper part design, material selection, mold engineering, and machine capability.

With disciplined process control and advanced equipment such as accumulator-assisted high-speed injection machines, thin wall injection molding provides manufacturers with a decisive competitive edge in cost, sustainability, and production performance.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/