Back Pressure Settings and Effects: A Key Factor in Injection Molding

2025-10-30 08:59:51

Back pressure affects the melt’s density, uniformity, gas venting, and filling stability, which in turn determines product dimensional accuracy, surface quality, and mechanical performance. Many engineers tend to focus only on injection pressure and speed while neglecting the importance of back pressure. In fact, proper back pressure settings can significantly improve process stability, reduce defect rates, and optimize the structural strength and surface appearance of molded parts.

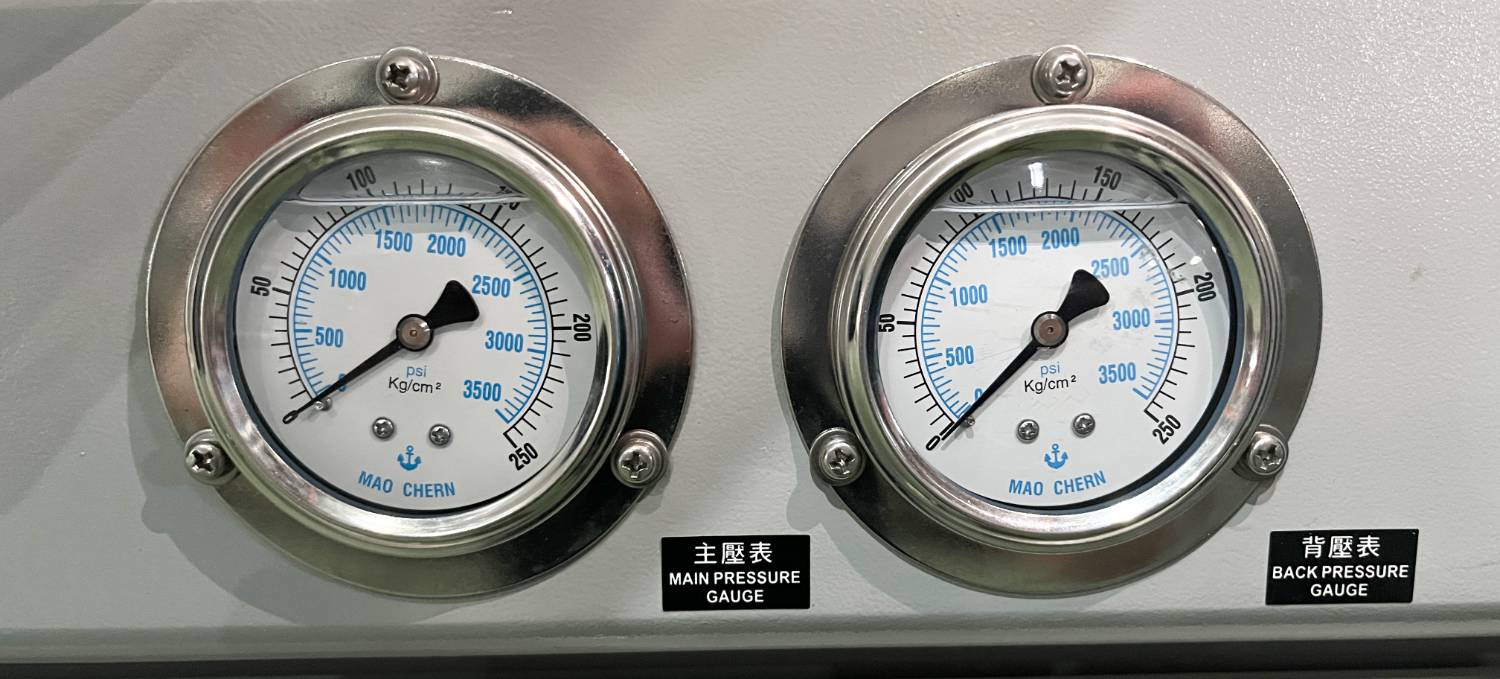

Back pressure refers to the reverse pressure applied to the screw during the plasticizing stage as it retracts. This pressure further compresses and homogenizes the molten plastic within the barrel, promoting uniform melt density, temperature, and viscosity. At the same time, it helps expel trapped air and moisture, ensuring consistent melt conditions for every injection cycle.

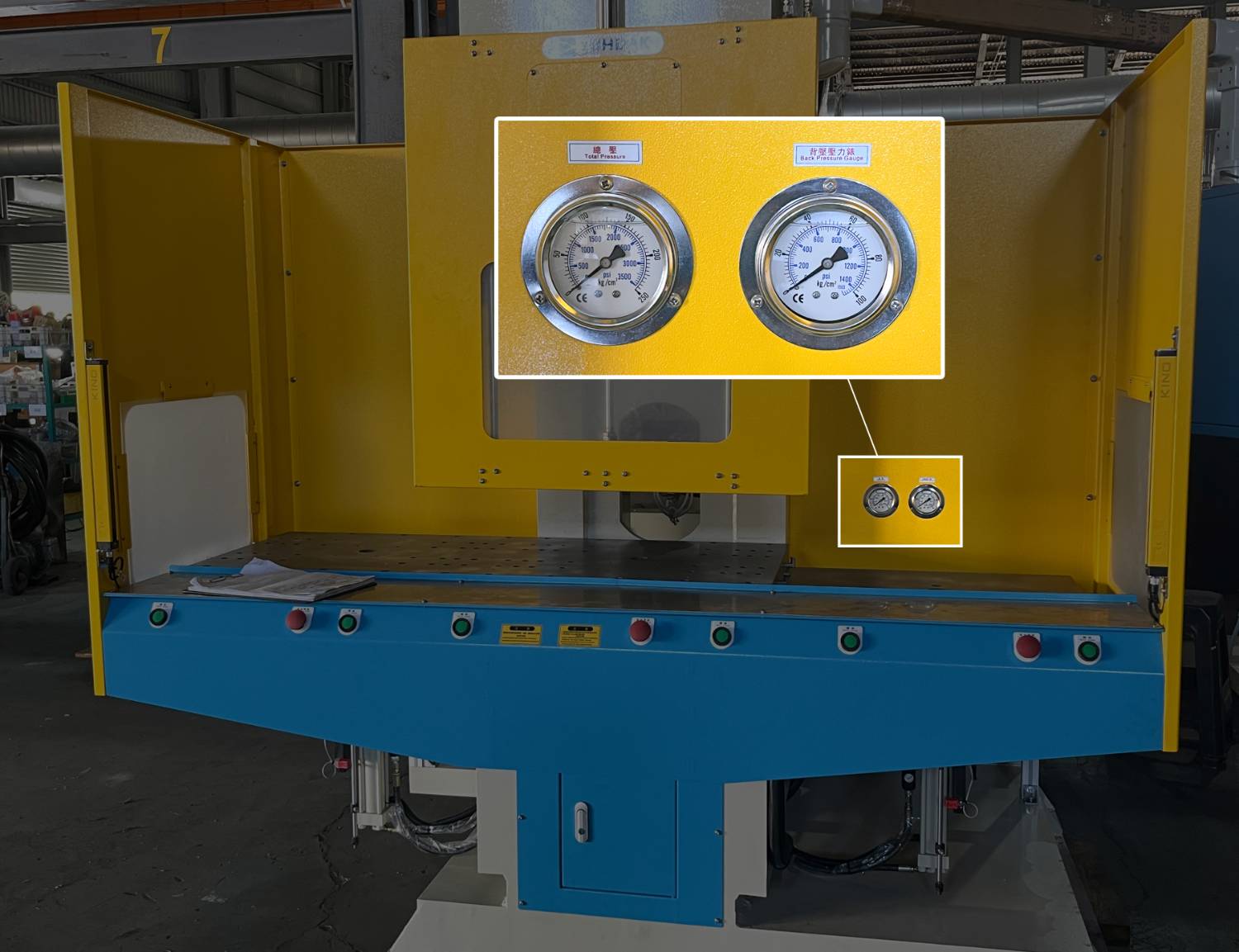

| Machine Type | Method of Generating Back Pressure | Control Characteristics | Suitable Applications |

| Hydraulic Injection Molding Machine | Restricting hydraulic oil flow to create counterpressure | High stability, slower response | Conventional molding processes |

| Servo Electric Injection Molding Machine | Servo motor controls screw resistance | Fast response, high precision | Precision molding applications |

| Hybrid Injection Molding Machine | Combination of hydraulic and servo control | Balanced stability and precision | High-efficiency mass production |

Related content:Servo System Power Unit

Back pressure plays multiple critical roles in injection molding, which can be summarized as follows:

Proper back pressure increases shear mixing between screw flights, promoting uniform temperature and viscosity distribution. It also aids in the even dispersion of pigments, additives, and fillers, improving part appearance and color consistency.

Back pressure compresses the polymer melt, increasing and stabilizing its density. A consistent melt density ensures uniform shot volume during injection, minimizing fluctuations in part weight and dimensions.

During screw recovery, back pressure helps force trapped gases and moisture out of the melt, thereby reducing common molding defects such as bubbles, silver streaks, sink marks, and short shots. This ensures complete cavity filling and better part integrity.

Moderate compression slightly increases melt temperature while reducing viscosity, which enhances the flow of the melt through long runners, thick walls, or multi-cavity molds. This results in better pressure balance and consistent cavity filling.

Back pressure compacts the molecular structure of the melt, reducing internal voids and increasing material density. This leads to improved mechanical strength, surface smoothness, and gloss of the finished product.

Even slight variations in back pressure can cause significant differences in product quality. When properly adjusted, the compression and mixing of the melt inside the barrel reach an optimal balance, resulting in smooth surfaces, uniform color, and stable dimensions. Consistent melt density also ensures uniform part weight and volume across cycles, improving both appearance and structural performance.

- Surface Quality:Homogeneous melt minimizes flow marks, bubbles, and color streaks, producing a smooth and glossy surface.

- Dimensional Accuracy:Stable shot density and filling pressure reduce sink marks and warpage, enhancing dimensional consistency.

- Mechanical Properties:Uniform melt density and reduced air entrapment improve tensile strength, impact resistance, and wear performance.

- Filler and Fiber Dispersion:Back pressure promotes even distribution of fillers and glass fibers, preventing fiber breakage or clustering, which enhances strength and appearance.

| Material Type | Suggested Back Pressure Range | Remarks |

| General Plastics (ABS, PP, PE) | 500–1000 psi (≈3–7 MPa) | Suitable for most molding conditions |

| Glass-Filled or Highly-Filled Plastics | 700–1200 psi | Requires higher mixing energy需更高混煉能量 |

| Heat-Sensitive Materials (PVC, POM) | 300–600 psi | Avoid excessive shear and degradation |

1. Start from a Low Setting → Establish a baseline process.

2. Adjust Screw Speed → Identify the most stable recovery speed and mixing condition.

3. Increase Back Pressure Gradually (about 50 psi per step) → Observe changes in part appearance and weight.

4. Find the Optimal Point → Maintain the lowest back pressure that still ensures consistent quality.

5. Verify with Data Monitoring → Track screw recovery time, shot weight, and CPO (Cushion Pressure Output) indicators to ensure long-term stability.

When setting back pressure, special attention should be given to resin viscosity, thermal sensitivity, mold runner design, venting, and temperature control stability. Each resin type and mold structure may require fine-tuning to achieve optimal melt conditions and product performance.

| Problem | Possible Cause | Corrective Action |

| Excessive Back Pressure | Melt overheating, color variation, high screw torque | Reduce back pressure, adjust barrel temperature, clean the screw |

| Insufficient Back Pressure | Poor melt mixing, bubbles, or short shots | Increase back pressure, adjust screw speed, improve material drying |

| Unstable Shot Volume | Moisture absorption, poor venting | Control material drying, increase back pressure, check mold venting |

| Uneven Filling in Multi-Cavity Molds | Runner pressure imbalance | Adjust back pressure, re-evaluate runner design |

Although back pressure is considered a fine-tuning parameter in injection molding, mastering its control is essential for achieving process stability and product quality. Proper adjustment ensures smooth molding operations, minimizes production risks, and maintains consistent part dimensions, surface appearance, and structural performance throughout mass production.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/