Injection Molding Auxiliary Equipment (Part 2): Advanced Systems & Special Processes

2025-09-17 13:04:58

As injection molding operations scale, so do the expectations for efficiency, sustainability, and advanced process capabilities. If you're just getting started, be sure to read our Injection Molding Auxiliary Equipment: A Beginner’s Guide to learn about essential systems like dryers, chillers, conveyors, and automation.

In this article, we go beyond the basics and explore 2 advanced categories of injection molding auxiliary solutions to optimize performance, adopt lean manufacturing practices, or explore new product possibilities.

The recycling system in an injection molding business is designed to reduce waste and lower material costs by reusing sprues, runners, and rejected parts. When properly managed, this system helps maintain sustainability while ensuring production efficiency.

A crusher, also known as a granulator, grinds waste plastic into small, reusable pellets called regrind.

- Function: Cuts and grinds thick sprues, runners, or defective parts into uniform chips or granules.

- Types:

- Slow-speed crushers for soft and thin sprues.

- High-speed granulators for hard, thick, or large parts.

A regrind tank is a storage bin that holds crushed material (regrind) before it is reused. It acts as a buffer between the crusher and the auto-feeding system. It helps keep the workspace clean and organized while enabling controlled reuse of materials.

- Function: Temporarily stores regrind to ensure even feeding and avoid clogging or bridging.

- Application: Usually placed beside the molding machine, connected to the main loader or a dosing device.

An auto mixer or proportional valve mixer blends virgin material with regrind or color masterbatch at a consistent ratio. Ideal for maintaining consistent melt flow and mechanical properties in regrind-containing parts.

- Function: Maintains accurate and repeatable mixing proportions (e.g,. 80% virgin + 20% regrind).

- Types:

- Volumetric (timer-based, simpler)

- Gravimetric (weight-based, more precise)

- Benefits: Prevents product quality variation due to inconsistent material blends.

These systems support advanced molding techniques for injection molding machines that expand your product range or reduce material usage.

A gas-assisted injection molding system injects nitrogen gas into the melt stream during or after plastic injection molding to create hollow sections within the part.

- Function: Displaces molten plastic in thicker areas with gas, forming internal channels and reducing material usage.

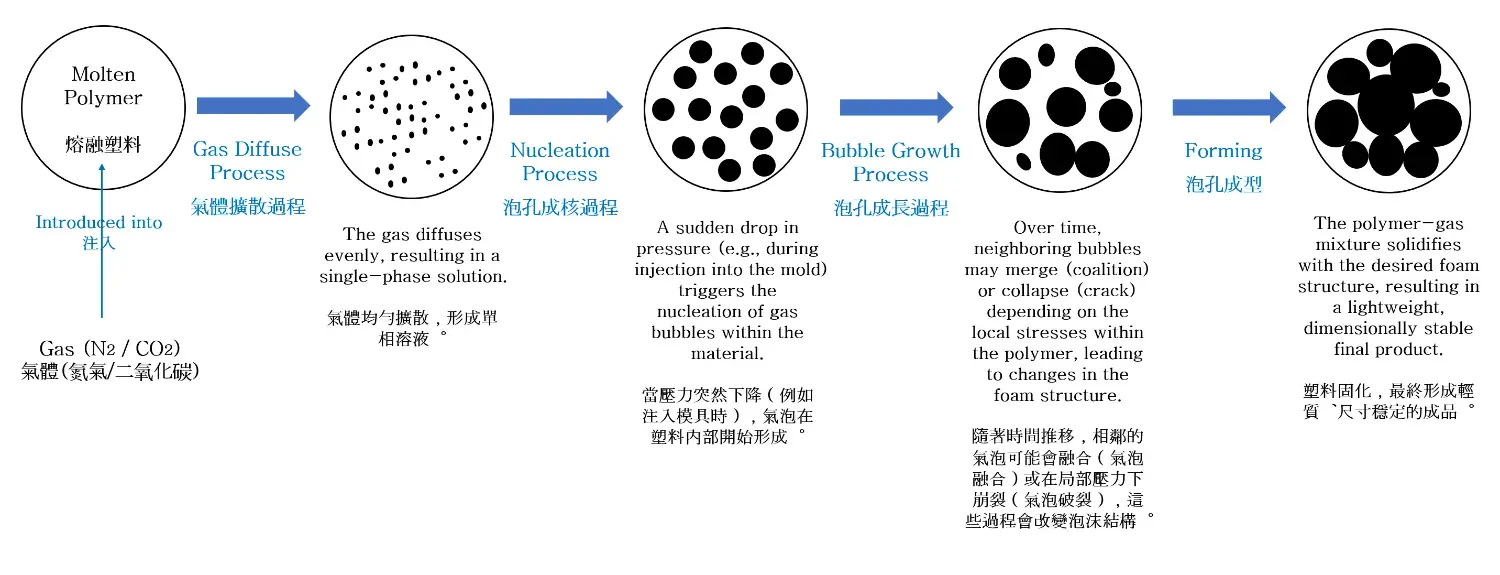

A microcellular foaming system introduces a supercritical gas (typically N₂ or CO₂) into the molten plastic before injection, resulting in fine cell formation during molding.

- Function: Creates a uniform cellular structure inside the molded part, reducing density while maintaining rigidity.

- Technology Notes:

- Requires a modified screw/plasticizing system

- Ideal for large parts or products with dimensional tolerances

- Benefits:

- Up to 20–30% material saving

- Faster cooling and ejection

- Improved dimensional stability

Related article: Microcellular Foaming – Revolutionizing Lightweight Injection Molding

While both recycling systems and special molding processes offer tremendous benefits, the right choice depends on your production goals, product requirements, and facility setup. Here's how to decide:

| Scenario | Recommended System |

|---|---|

| High scrap rate from sprues or runners | Crusher + Regrind Mixer |

| Customer requires sustainability report or carbon footprint tracking | Closed-loop recycling + material flow monitoring |

| Thick parts prone to sink marks or internal stress | Gas-Assisted Molding |

| Lightweight products with cost-saving goals | Microcellular Foaming |

| Product has cosmetic or surface finish challenges | Microcellular Foaming or precise thermal control |

| High mix, low volume manufacturing | Combine foaming with Quick Mold Change (QMC) |

Not recommended. Regrind should be:

- Dried properly

- Mixed with virgin resin using an auto mixer

- Controlled for proportion and consistency

Otherwise, it may cause unstable melt flow and poor product quality.

They are fundamentally different in timing, method, effect, and application.

| Aspect | Gas-Assisted Injection Molding | Microcellular Foaming (Physical Foaming) |

|---|---|---|

| Gas Timing | Injected after or during plastic injection into mold | Injected before plastic injection (during plasticizing) |

| Gas State | Compressed nitrogen gas | Supercritical gas (N₂ or CO₂) dissolved in melt |

| Mechanism | Forms hollow internal channels in thick sections | Forms fine, evenly distributed microcells inside the part |

| Part Structure | Partially hollow (e.g. D-shaped or tube-like inside) | Fully solid but foamed (microcellular structure) |

| Target Benefit | Reduces sink marks, shortens cooling time, strengthens thick sections | Reduces part weight, lowers material usage, improves dimensional stability |

| Design Requirement | Needs special gas channel design in mold | Requires modified screw/plasticizing unit to inject gas |

| Applications | Chair frames, automotive handles, large bezels | Dashboards, control panels, electronic housings |

- Injection Molding Business: A Complete Guideline of How to Start

- PET Preform Production Line Planning Guide: From Bottle Buyer to In-House Manufacturing

- Injection Molding Cycle Time: The Key to Faster and Smarter Manufacturing

- Injection Molding Auxiliary Equipment: A Beginner’s Guide

Injection molding auxiliary equipment is crucial to meeting modern manufacturing demands for speed, sustainability, flexibility, and cost efficiency. From closed-loop material reuse to innovative molding techniques like gas-assisted and microcellular foaming, these tools open up new opportunities for part design, cycle time optimization, and waste reduction.

At Huarong, we not only build reliable injection molding machines—we partner with customers to design complete production ecosystems that integrate automation, efficiency, and future-ready technologies.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/