Huarong at K Show2025: Witness a 24/7 Automated Factory & Get Your Free Gift!

2025-08-15 09:18:52

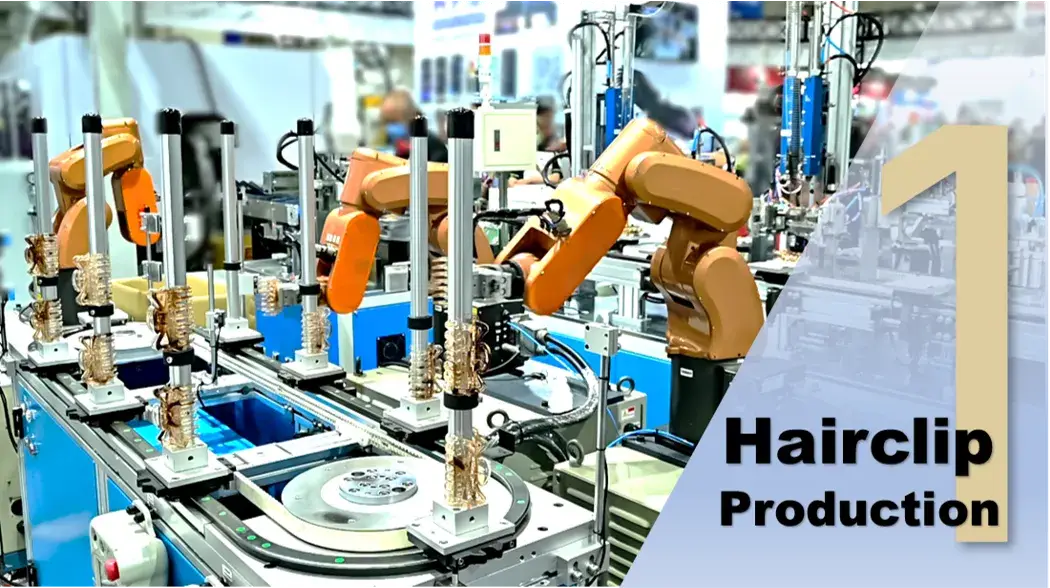

Planning your trip to the 2025 K Show? The Huarong team is excited to welcome you to our booth in Düsseldorf for an unforgettable look into the future of manufacturing. We’re rolling out our most advanced solutions, including a live, seamless production line that runs itself, and you’re invited to see it all and take home a finished hairclip as a souvenir.

As the world’s No. 1 plastics and rubber exhibition, K Show is the premier stage for showcasing cutting-edge technology. Accordingly, Huarong will present a market-proven, factory-ready turnkey solution, demonstrating a fully automated dual-color hair clip production line designed for 24/7 lights-out operation with zero manual labor. This system is a powerful showcase of Huarong's capability to help manufacturers scale production, boost productivity, and reduce labor costs by up to 70%—a must-see highlight of the exhibition.

| Fast Facts | Details |

| Event | K Show 2025 (K Fair 2025) |

| Dates | 8 – 15 October 2025 |

| Venue | Messe Düsseldorf, Germany |

| Booth | Hall 12, C01-13 |

The fully automated hairclip line showcases a harmonious system. But what about the core technologies behind it? We'll explore the full production cell and the powerhouse machines that enable it. Discover the high-performance building blocks, from dual injection molding to vertical injection molding solutions, that make our systems possible.

The star of our booth is a proven, factory-ready turnkey solution. This is your chance to see a complete "lights-out" smart factory operating live, demonstrating how to achieve massive gains in productivity and efficiency.

| Key Metric | Value |

| Cycle time | ≈ 30 s (8+8 cavity mold) |

| Materials |

|

| Throughput | Up to ~960 clips per hour |

- Double-Shot Molding – rigid outer + soft inner for anti-slip grip

- Robotic Transfer – custom-stroke arm; ±0.2 mm repeatability

- Spring & Pin Assembly – inline, hands-free, QA-checked

- Thread-Through Packaging – silicone-band fix onto card, ready to ship

Further reading: Hair Clip Automation System – Dual-Shot, 24/7, Fully Automated

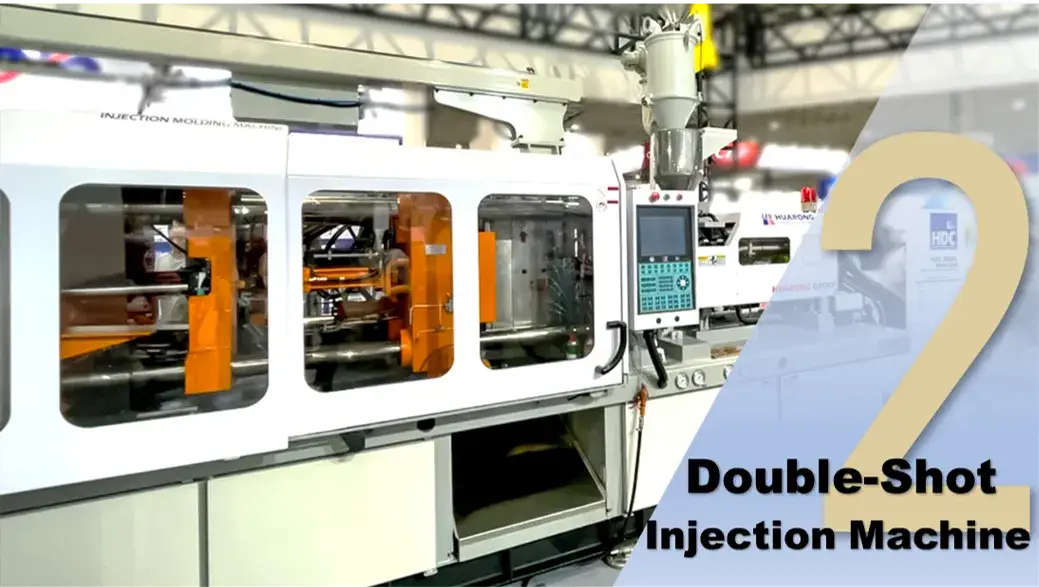

The powerhouse behind the automation line, the HDC-300FC, is a double injection molding machine that is engineered for ultimate precision in two-color molding.

| Spec | 28 mm Screw | 42 mm Screw |

|---|---|---|

| Shot volume (cm³) | 86 | 277 |

| Shot weight (PS, g) | 78 | 252 |

| Injection rate (cm³/s) | 69 | 154 |

| Injection speed (mm/s) | 113 | 111 |

| Clamping Force (Tons) | 300 | |

- Patented safety rotary table (M391464) — triple locking (mechanical + electrical + hydraulic) so the table never drops.

- External gearing — faster indexing, ±0.05° accuracy.

- Servo-drive rotation (option) — 15-30 % energy cut vs. hydraulic motors.

- Swappable table ↔ rotating shaft — toothbrush handles, headphone shells, or any 180° part.

- Optional T- / L-type 3rd injector — 2-colour → 3-material without new press.

Further reading: Double Injection Molding Machine – Dual-Color Precision

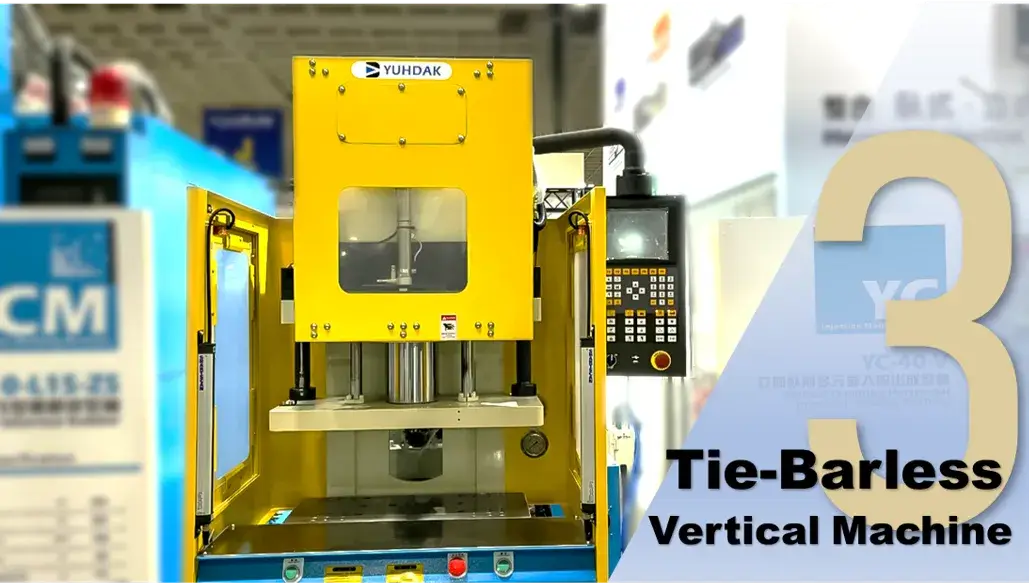

A tie-barless design of vertical injection molding machine creates a three-sided open space. This makes it incredibly easy for operators to handle embedded parts and allows for seamless integration with automation systems.

| Spec | 36 mm Screw |

|---|---|

| Shot volume (cm³) | 137 |

| Shot weight (PS, g) | 124 |

| Injection rate (cm³/s) | 76 |

| Injection speed (mm/s) | 75 |

| Clamping Force (Tons) | 40 |

Related product: Tie-bar-less horizontal injection vertical clamping machine– YC Series

Although not physically exhibited at K Show 2025, Huarong continues to advance and promote cutting-edge molding technologies that align with sustainability and innovation goals. Our latest technical catalog highlights two standout capabilities that are already deployed in customer factories: Microcellular Foam Injection Molding and Mixed Dual-Color Injection — both delivering performance, efficiency, and visual value.

By injecting nitrogen or CO₂ into molten resin, this technology creates a uniform foamed structure that reduces material usage while enhancing dimensional stability.

Key benefits include:

- 15–20% part weight reduction

- 30–50% less clamping force required, extending mold life

- Zero holding pressure, minimizing defects like sink marks or flash

- Energy-efficient and ideal for lightweighting across industries

Further reading: Microcellular Foaming – Revolutionizing Lightweight Injection Molding

Achieve stunning visual effects directly in the mold, eliminating the need for secondary processes like painting or printing. Our mixed dual-color injection techniques offer creative freedom with the simplicity of a single mold.

- Co-Injection (Sandwich): Two materials are injected in layers to create a distinct skin-core-skin structure.

- Split-Petal Injection: Materials flow through segmented gates to produce beautiful, petal-like multi-color effects.

- Gradient Injection: Creates a smooth, seamless color transition across the length of the part.

- Mix-Injection (Marbling Effect): By partially blending materials, this technique forms elegant swirls and marble-like patterns inside the mold.

These effects are increasingly used in consumer electronics, home goods, and automotive interiors, where design and material synergy drive brand value.

Related article: Injection Molding Color Mixing and Marbling Effect: Process, Color Swirl Techniques, and Application

You can find us in Hall 12, stand C01-13, located near Entrance East.

The automated line runs continuously, with main demonstrations every 30 minutes.

Yes! Please send an email to our official email address, [email protected], to schedule a dedicated time slot with our engineers.

Absolutely! We welcome you to grab a freshly made dual-color clip right off the line.

Yes, with the optional T- or L-type auxiliary injector, it can be configured for 3-material and multi injection molding.

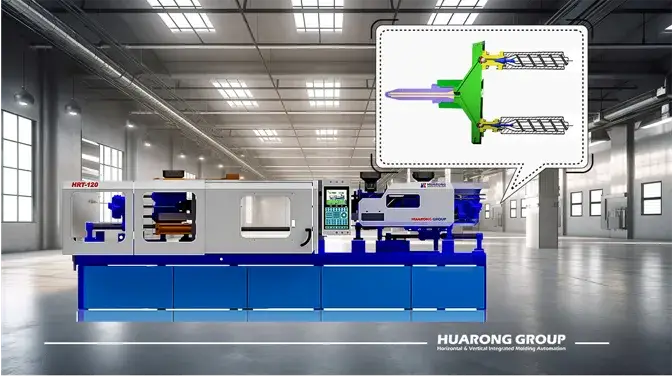

Whatever your injection molding challenge, Huarong is ready to be your most trusted partner. Our comprehensive portfolio is designed to meet your every need—from high-performance horizontal and vertical machines to advanced multi-shot systems and a fully integrated smart factory management and automation system.

The 2025 K Show is the perfect opportunity to connect. We look forward to welcoming you to Hall 12, Booth C01-13!

- Founded in 1986 in Taiwan.

- Offers a complete range of horizontal, vertical, and multi-shot machines, plus turnkey automation.

- Holder of patented technologies and certified by CE & ISO 9001.

- Supported by global service hubs across Asia, Europe, and the Americas.

- Our Mission: Industry Alliances Create Value, Innovation Delivers High Quality—proven by the award-winning solutions you’ll see at K Fair 2025.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/