Weld Lines in Injection Molding: A Practical & Professional Guide

2025-07-31 14:13:16

Weld lines are a common and persistent issue in the injection molding process. They occur when two streams of molten plastic meet inside the mold but do not bond seamlessly. From an engineer’s view, weld lines are more than just cosmetic flaws—they can be weak points in the structure. On the shop floor, weld lines resemble two molten flows shaking hands in the mold, but their grip is cold and weak. The handshake leaves a visible mark—the line—and the bond strength is less than that of the rest of the part. This guide covers what weld lines are, why they form, and how to minimize them by integrating engineering insights.

To solve weld lines, you need to understand their formation. In molding, molten plastic sometimes has to split around obstacles and then meet again. If the plastic is too cool or the flow is poor when it meets, the bond is incomplete.

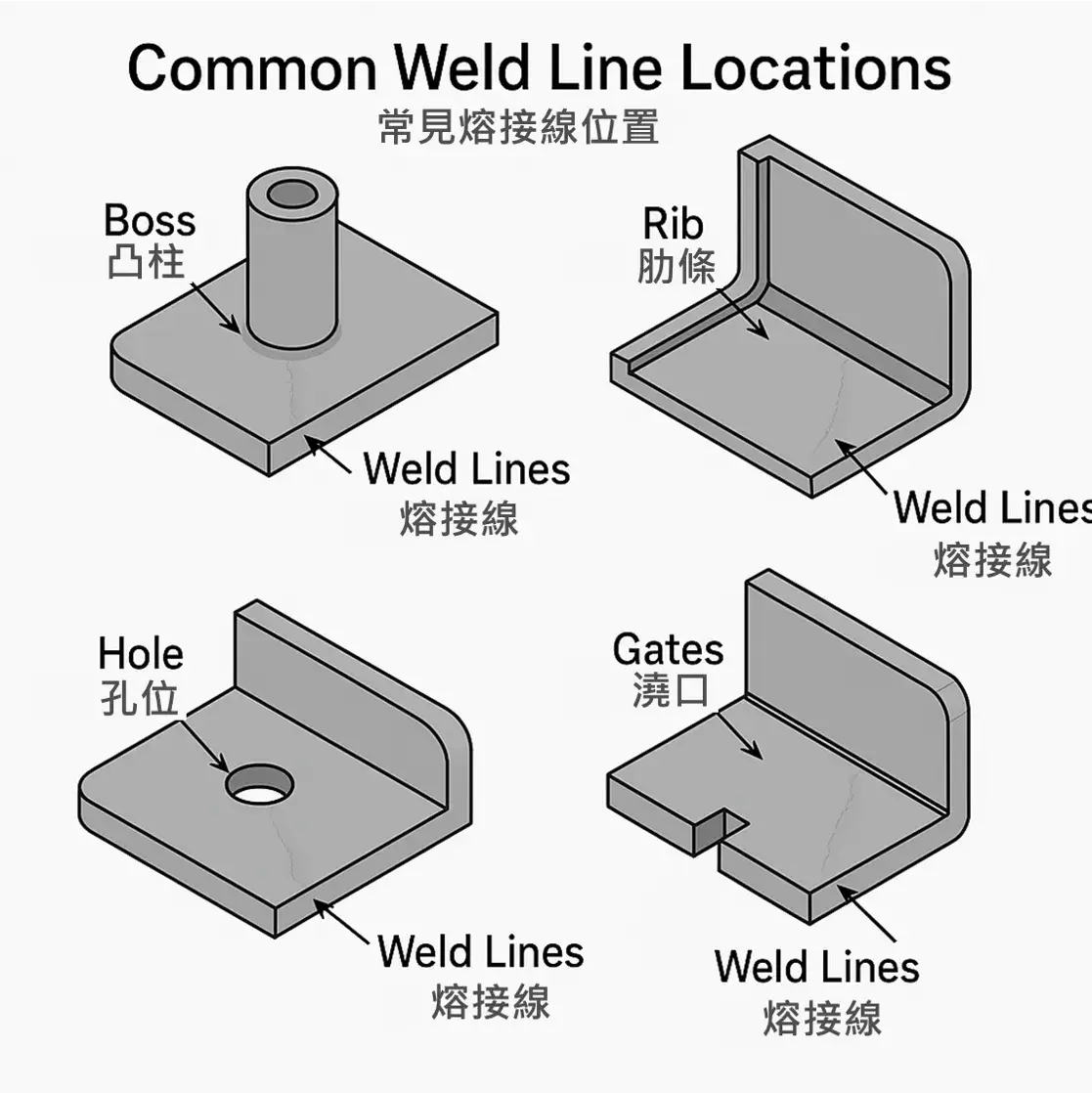

- When molten polymer enters the mold, obstacles like bosses, ribs, or inserts can split the flow.

- These split flows travel along separate paths and cool slightly, forming a thin solid “skin.”

- When they meet again, the skins prevent full molecular bonding.

- Result: a visible weld line and a weak spot in the part.

Cold weld lines arise when insufficient melt temperature or inadequate injection pressure prevents effective polymer fusion. They are visibly distinct, mechanically weak, and highly prone to fracture under stress.

Hot weld lines form under higher injection pressures and mold temperatures. However, generally stronger and less visible, improperly managed conditions may still yield minor structural and aesthetic concerns.

Clearly distinguishing weld lines from meld lines is essential:

Formed when melt fronts collide head-on, causing significant air entrapment, insufficient polymer bonding, and structural weaknesses.

Formed at shallower angles where melt fronts merge and flow parallel, offering improved molecular mixing, stronger bonding, and reduced visibility compared to weld lines.

To effectively minimize weld lines, engineers must consider several interconnected factors during molding.

Injection pressure has a significant influence on weld line formation.

- Low pressure → melt hesitates, cools too fast before meeting.

- Proper pressure & injection speed ensure the melt meets while still hot.

Proper melt temperature ensures adequate polymer flow.

- Low melt temperature → plastic is too thick to flow and bond well.

- Low mold temperature → surface cools too fast, forming skin before meeting.

Gate placement dictates polymer flow behavior within the mold.

- Poor gate location can push weld lines into visible or critical strength areas.

- Ribs, bosses, holes almost always create weld lines unless gates are strategically placed.

Material selection plays a crucial role in the visibility and strength of weld lines. Different resins have different weld line sensitivity:

| Resin Type | Weld Line Visibility | Strength Reduction | Remarks |

|---|---|---|---|

| PP, PE (Crystalline) | Low | Minor | Low viscosity and crystalline structure reduce the visual impact of weld lines. |

| PC, ABS, PMMA (Amorphous) | High | Moderate to High | Amorphous nature increases visibility; careful temperature and flow control are required. |

| GF-Reinforced Grades | High | Severe | Fiber orientation at the weld line reduces bonding strength; optimized gate location and RHCM are recommended. |

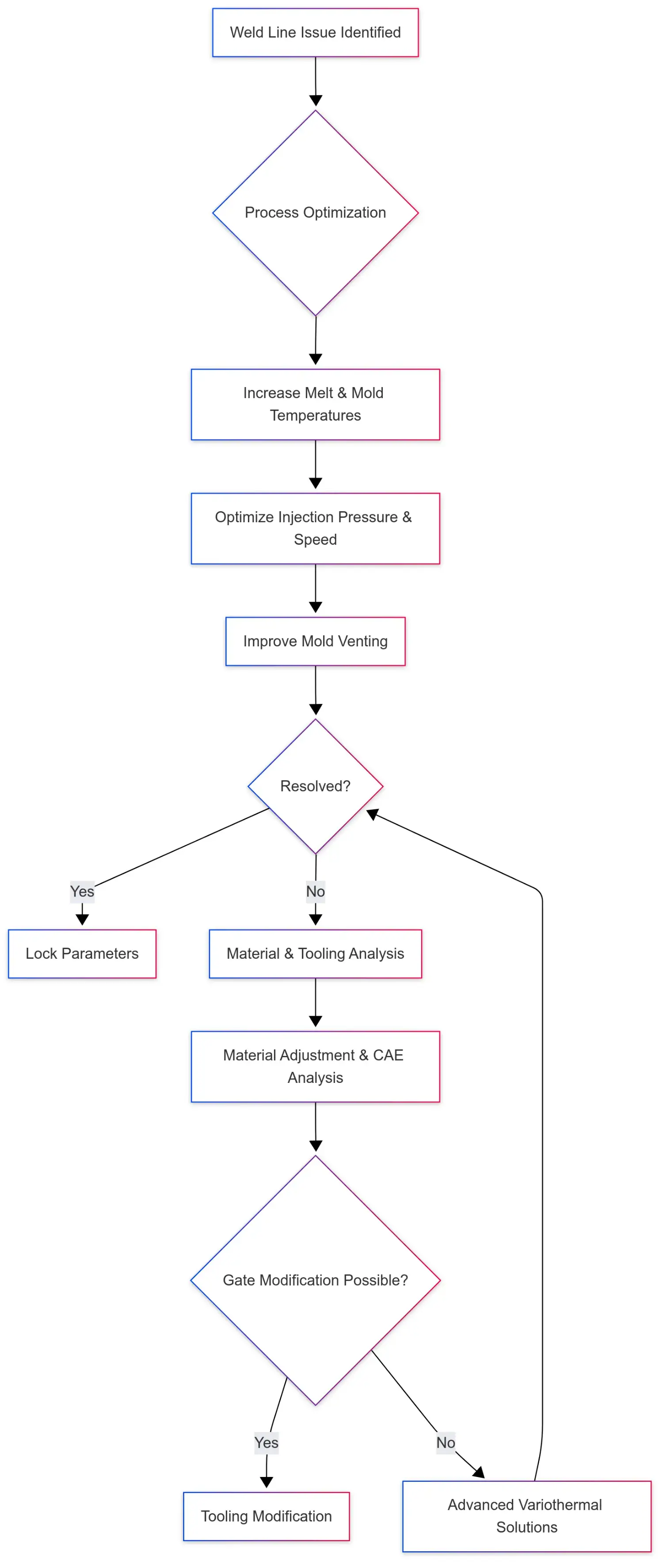

In real production, engineers and technicians work in order of easiest to most costly:

- Injection Pressure & Speed (First Priority)

- Increase injection pressure to ensure rapid mold filling.

- Adjust injection speed to maintain melt front temperature during convergence.

- Melt & Mold Temperature (Second Priority)

- Elevate melt temperature within safe resin limits to improve molecular mobility.

- Increase mold temperature to delay skin layer solidification at convergence points.

- Gate Location & Flow Balancing (Requires Tooling Adjustment)

- Modify gate placement to redirect weld lines to non-critical or concealed areas.

- Balance runner layout to synchronize melt front arrival at weld line location.

- Advanced RHCM or Material Change (High-Cost Options)

- Apply Rapid Heat Cycle Molding (variothermal control) to enhance surface and strength.

- Consider resin grade adjustments, such as high-flow or impact-modified versions, if design constraints persist.

For technical and engineering teams, a structured approach helps prioritize improvements:

- Injection Pressure & Speed: Ensure rapid cavity filling to reduce cooling before convergence.

- Melt & Mold Temperature: Keep resin temperatures within optimal ranges to maintain mobility.

- Ventilation: Improve mold venting to avoid trapped gas that weakens weld lines.

- Gate Relocation: Position gates so weld lines form in hidden or non-critical zones.

- Runner Balancing & Overflow Wells: Balance flow to improve convergence quality.

- Material Enhancements: Use low-viscosity or impact-modified resins for better bonding.

- Temporarily increase mold surface temperature at the moment of injection to keep convergence points hot.

- Rapid cooling follows to maintain production efficiency.

- Visual Inspection: Bright, angled lighting; magnification for fine details.

- Mechanical Testing: Tensile and impact testing at weld zones to confirm strength.

- Non-Destructive Testing (NDT): Ultrasound or CT scanning for hidden defects, especially in fiber-reinforced parts.

A weld line is like two streams of molten plastic meeting in the mold for a handshake—but the hands are cold, so they don’t grip well. That leaves a visible line and a slightly weaker spot in the part.

With higher pressure, the melt shoots faster and stays hotter when the flows meet, bonding better. Low pressure means the melt cools before meeting, and the weld line becomes more visible and weaker.

Weld lines are head-on collisions—air can get trapped, and bonding is poor. Meld lines meet at an angle, flowing in the same direction, letting air escape and bonding more smoothly with a less visible line.

Placing the gate in the right spot can push weld lines into non-visible or non-critical areas. Balanced runners and overflow wells also help flows merge more smoothly.

If you found this guide useful, you may also be interested in our other articles on injection molding quality and troubleshooting:

- Injection Molding Defects

- Repairing Injection Molding Machines

- Sink Marks in Injection Molding

- Short Shot in Injection Molding

- Burn Marks in Injection Molding

- Weld lines are a natural outcome of molding flow and cooling—you can’t always eliminate them, but you can control where they appear and how strong they are.

- Start with easy process adjustments before considering costly tooling or material changes.

- Plan gate location, runner balance, and part design early to avoid weld lines in critical spots.

- For high-end parts, RHCM or optimized material selection can make the difference between a reject and a passed part.

At Huarong Group, we leverage over 40 years of expertise in injection molding to assist customers with their real-world production challenges and needs. We provide injection molding machines and turnkey automation solutions, supported by robust technical support to ensure consistent quality and cost efficiency.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/