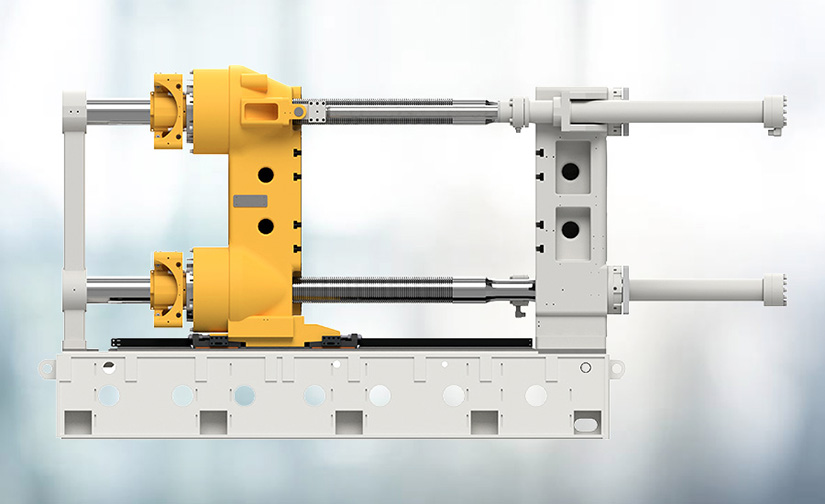

Inward Toggle Clamping

ー Cost-effective, Stable & Durable

Leading the industry for many years of experience, reasonable design with computer-aided design (CAD) on the injection molding machine to make mechanical structure stable and reliable, and easy to maintain and repair.

;?>)

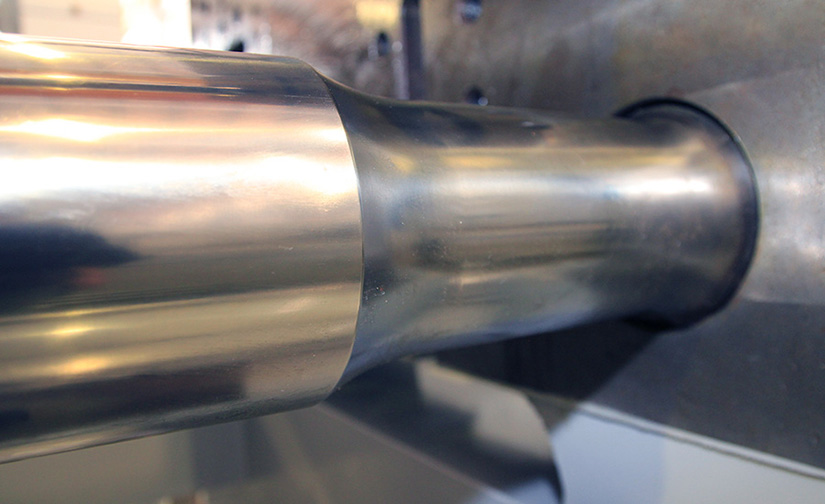

Tie bar insists on manufacturing in Taiwan and adopts the patented design of SCM440 non-rigid absorption method(patents 313046 & 334924 & 425836), which can reduce the deformation of the mechanical structure and ensure the parallelism.

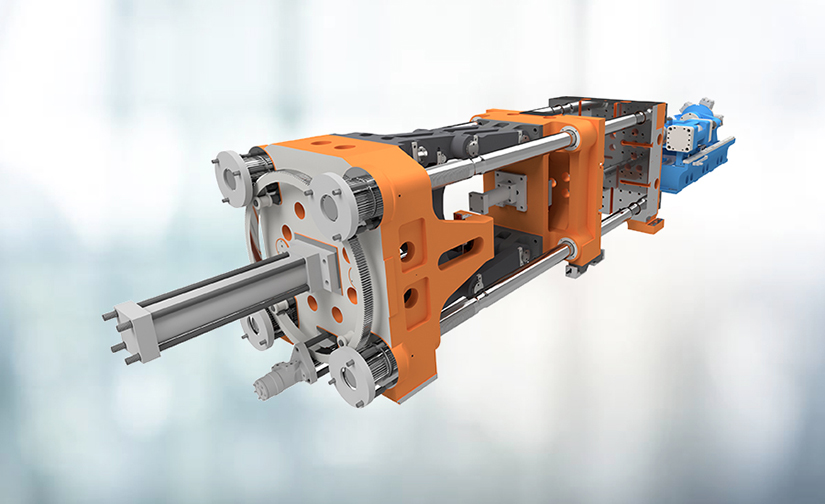

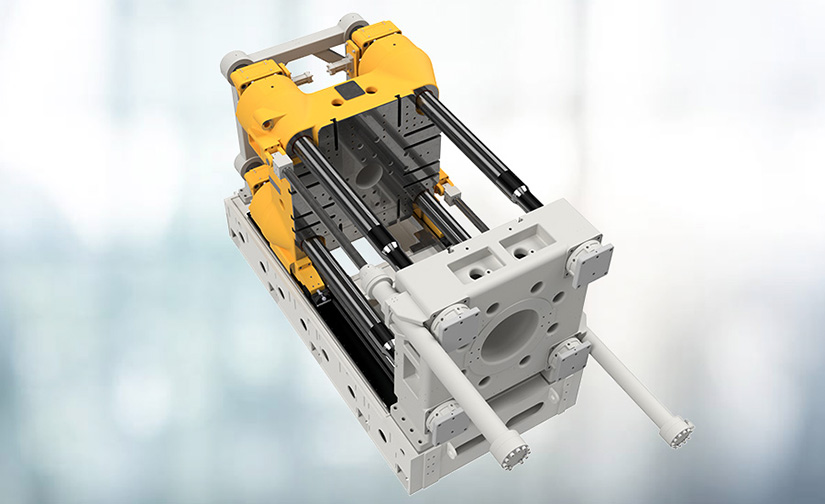

Outward toggle clamping

ー Short Machine Length, Long Opening Stroke

Shifted clamping cylinder to reduce 18% machine length.

40% shortened on the clamping cylinder.

20% enlarged on the opening stroke.

;?>)

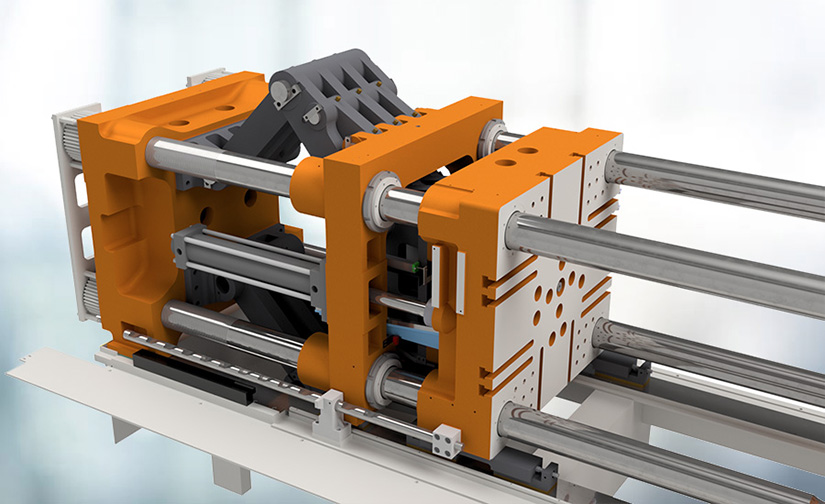

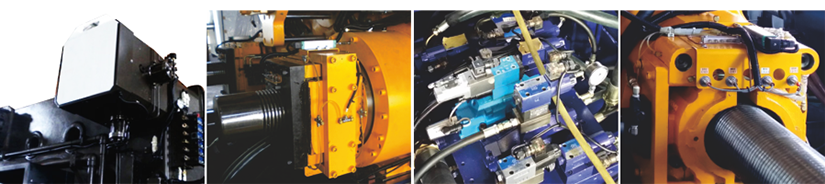

Two-platen clamping

ー Minimized machine length with maximized opening stroke

Compared with the toggle type, the mechanical size is shortened by about 20%, which saves the length and placement space and improves the utilization rate of the plant.

Built-in design on the ejection cylinder to minimize the machine length effectively.

Fully automatic mold-close adjustment.

Available option for additional stroke from opening.

Four direct pressure clampin cylinders make the mold not transform, which can prolong the life of the mold.

The high-pressure clamping stroke is small, and the clamping force can be quickly pressed.

Two-platen Clamping Patent:

- Suspended tie bars bearing module (patent number M634662)

- Supporting sliding module with an inner limit design (patent number M578643)

- Two-platen clamping positioning device for 100% assembly accuracy without manual correction (patent number M636571)

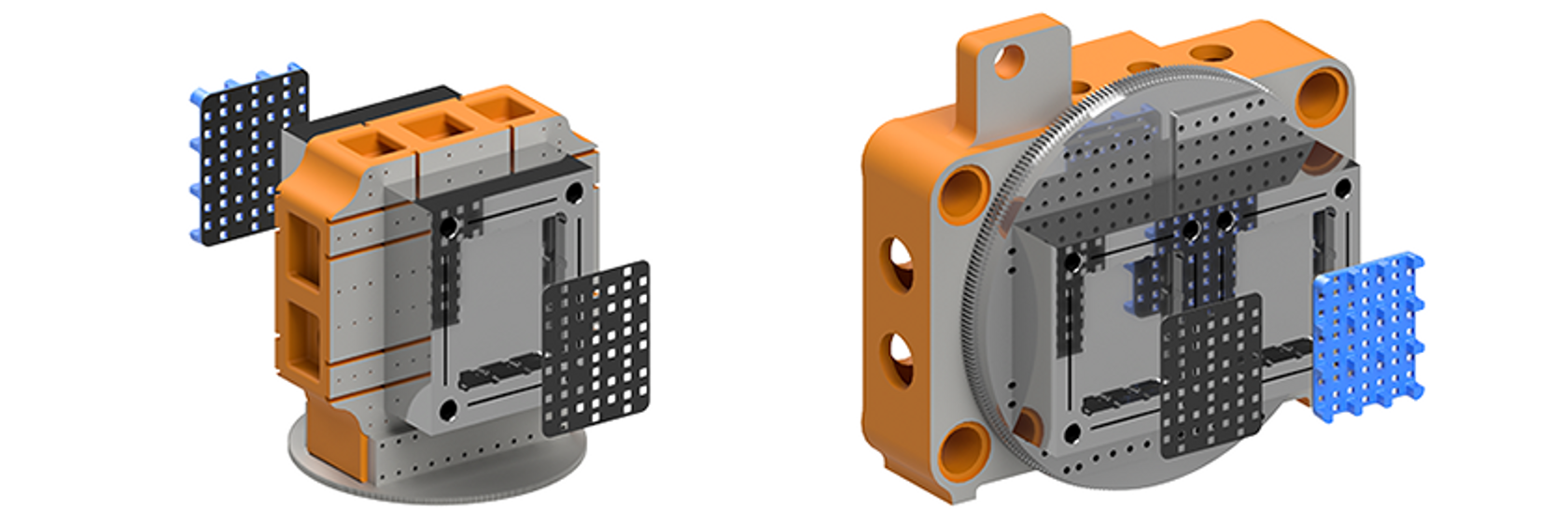

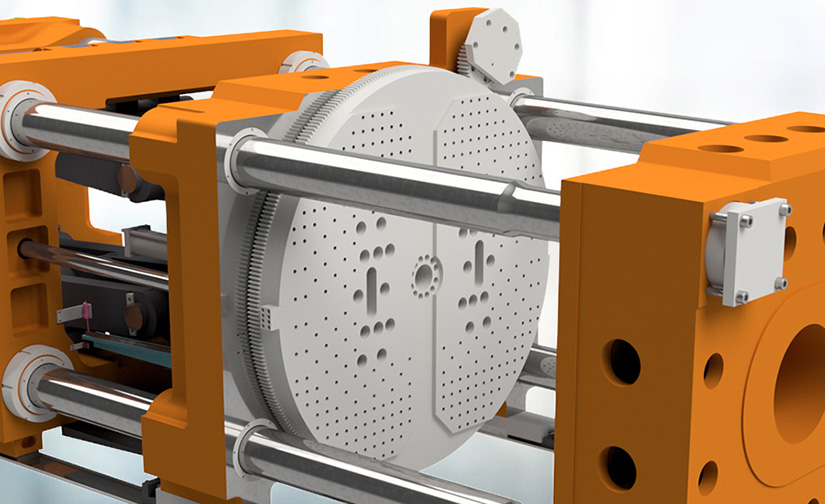

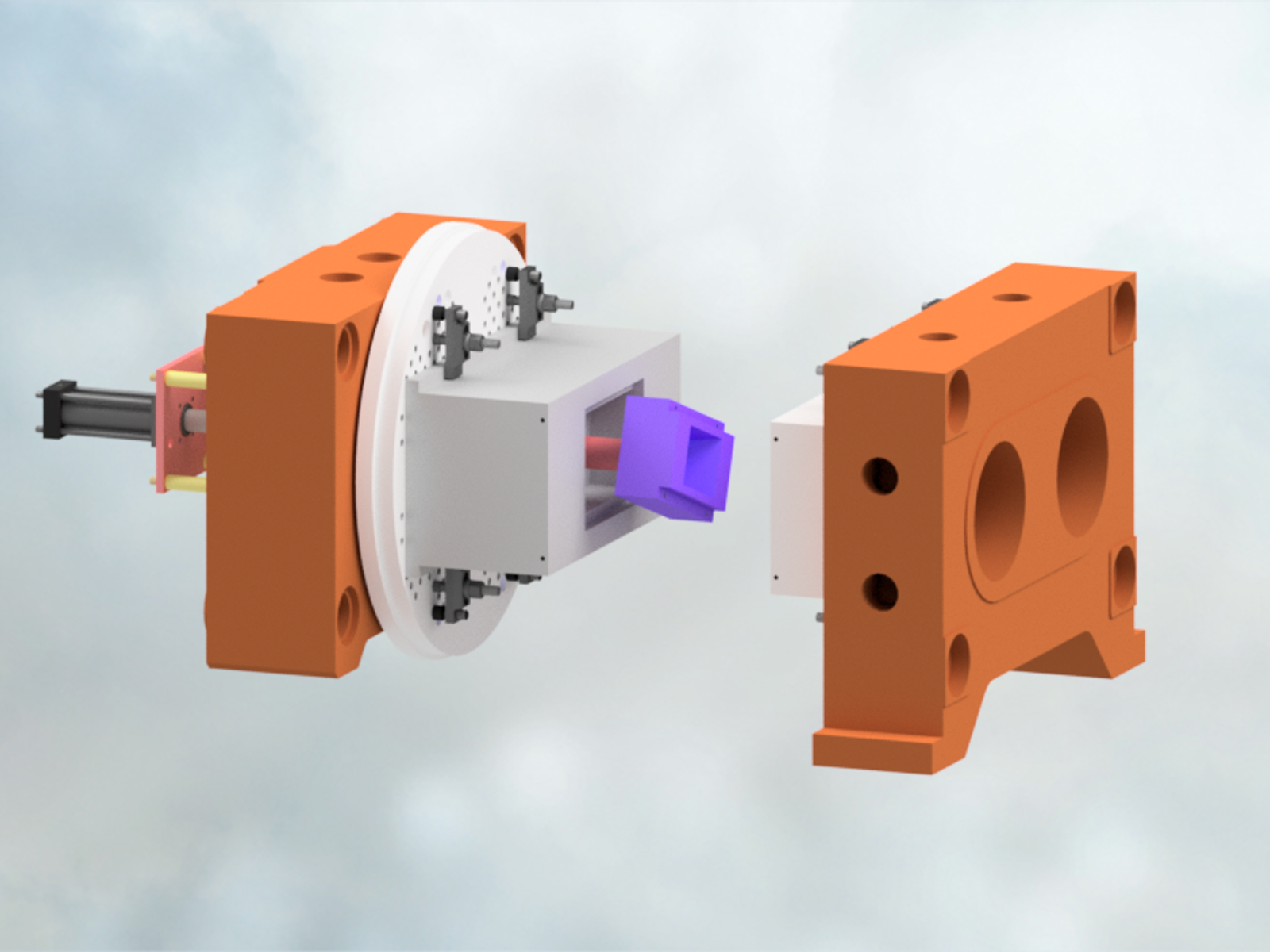

Rotary table clamping (patented)

ー The patented rotary table design ensures that the mold does not fall down and lean-free (patent number M391464)

Triple safety from mechanism, electric and hydraulic for rotation accuracy and never fall.

Products

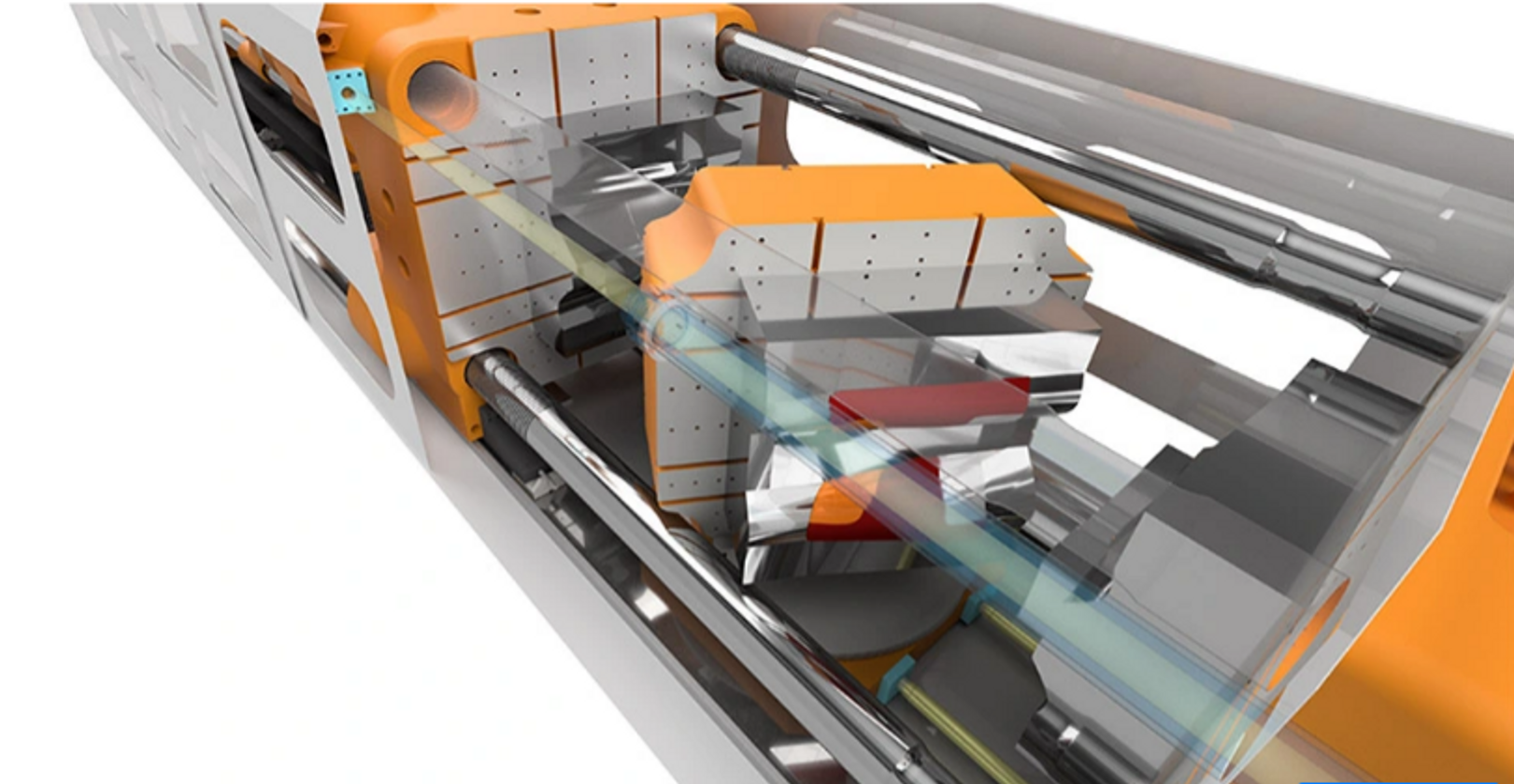

HDC Series (Dual injection)Rotary shaft clamping

ー for products that wrap around and penetrate

The shaft of rotation function is suitable for products that wrap around and penetrate through that the mold core needs to change the position, but the mold does not rotate.

The ejector system is equipped with a sensor to ensure that the mold core is reset.

Product

HDC Series (Dual injection)Horizontal rotary table clamping

ー Horizontal Turntable, Stable Structure

Spinning platen built on horizontal rotary, in-lined with axis and the center of gravity to be tilt-free from gravity.

With smaller tie bar distance but able to produce two same one/two-injection product, or two large products at the same time.