From Outsourcing to In-House Production:Building an Efficient Bottle Cap Line

2026-02-05 09:41:33

In the bottled beverage and consumer goods market, bottle caps are often regarded as structurally simple, low-unit-cost components, but once actual mass production begins, it becomes clear that bottle caps are in fact one of the key components in the entire packaging line with the highest requirements for stability and consistency.

A bottle cap manufacturing customer deeply realized that as the market moves toward high output, multiple specifications, and short lead times, relying solely on external suppliers or traditional equipment is no longer sufficient to support long-term corporate competitiveness.

In the past, the customer mainly relied on subcontracting and partial external purchasing of bottle caps to meet market demand. In the short term, this model could reduce initial equipment investment, but as order volumes increased, problems gradually emerged.

First was insufficient supply stability. Bottle caps are high-frequency consumables, and any slight delay in delivery directly affects downstream filling and shipment schedules. Second was the difficulty in controlling quality consistency. Tamper-evident ring breaking force, capping feel, and dimensional stability often varied between batches. Finally, the cost structure lacked flexibility, with transportation, inventory, and urgent order scheduling becoming hidden burdens.

These issues forced the customer to consider whether it was time to establish a truly self-owned bottle cap injection molding production line, taking control of quality and capacity at the source.

During the evaluation process, the customer quickly discovered that bottle caps are not simply about being molded successfully. What truly determines the success or failure of mass production lies in the following key factors:

- Stability of high-speed continuous injection:Bottle caps are multi-cavity, high-cycle products. Even slight fluctuations in injection pressure or injection speed can result in short shots, flash, or uneven weight.

- Consistency of the tamper-evident band structure:The tamper-evident function relies heavily on the quality of downstream cutting and folding. Any deviation may affect the opening feel.

- Reliability during long-term operation:Bottle cap production lines often require 24-hour continuous operation, making equipment durability and parameter stability critical.

Further reading:Bottle Cap Production Line: Injection Molding, Cap Mold, and Cap Slitting & Folding Integration

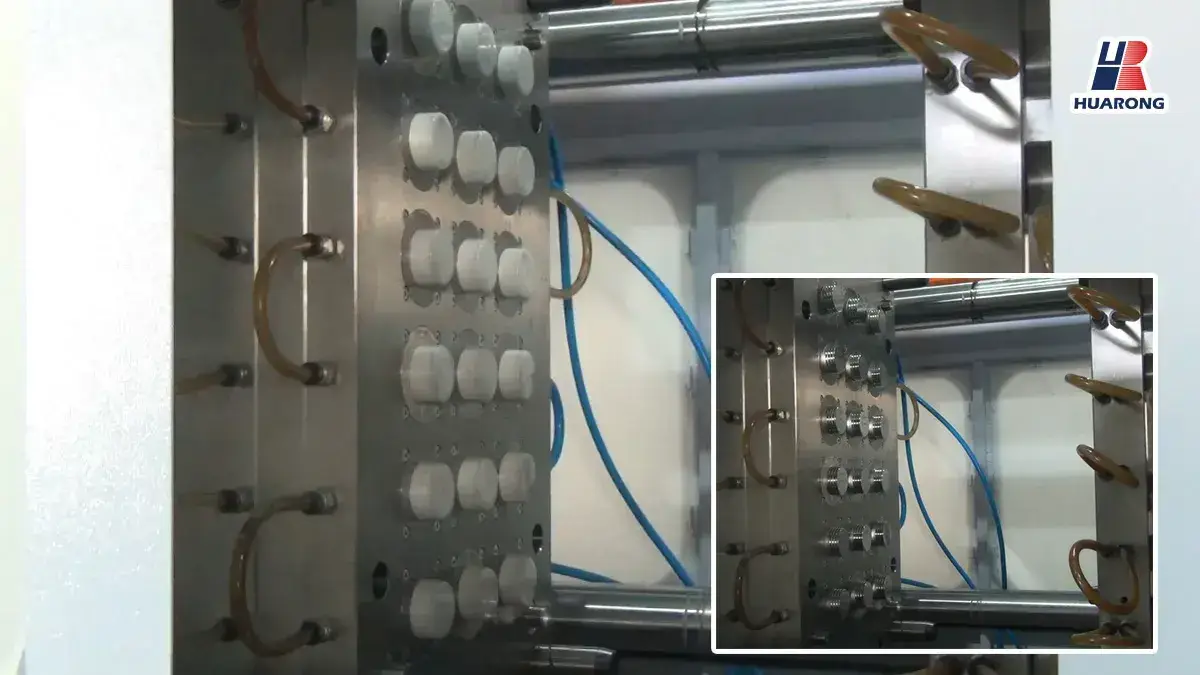

After extensive comparison, the customer chose to introduce a general-purpose injection molding machine as the core equipment for bottle cap injection, paired with multi-cavity molds specifically designed for bottle caps, and incorporated downstream tamper-evident ring processing into the same process planning.

The HRU & HRN series are Huarong's standard hydraulic injection molding machines, designed for the stable mass production requirements of various general plastic products, balancing molding accuracy, equipment durability, and operational safety. The following are the machine design and performance features:

- High-rigidity toggle clamping structure:

Provides fast clamping and high repeatability, suitable for long-term mass production of small- and medium-sized plastic products, ensuring stable product dimensions. - Stable and durable hydraulic power system:

Mature hydraulic design with smooth motion and stable control, meeting various general plastic molding conditions. - CE-certified safety protection module:

The entire machine complies with CE safety standards, balancing operational safety and export market regulatory requirements. - Patented detachable front safety guard design:

Improves accessibility to the mold area, enabling faster mold change and maintenance, effectively reducing downtime. - Inclined plate potentiometer mold position control:

Accurately detects mold position, stabilizes clamping force and injection conditions, and improves product consistency. - Patented slim-neck large-tie-bar structure + centralized lubrication system:

Enhances tie-bar rigidity and parallelism, reduces mechanical wear, and extends the service life of the machine and molds.

Many manufacturers planning bottle cap production lines in the early stages tend to underestimate the importance of the tamper-evident band. After actual implementation, they find that tamper-evident band processing is not an optional downstream operation, but one of the key factors determining bottle cap value.

Therefore, we chose to directly integrate cutting and folding equipment into the bottle cap injection production line, allowing the bottle caps to undergo tamper-evident band structure processing immediately after molding. Through stable control of cutting groove depth and folding angle settings, the tamper-evident band not only breaks at a consistent position but also provides a more stable tactile feedback during opening.

This in-line integration significantly reduces manual intervention and secondary handling risks while ensuring consistency in function and appearance for every batch of bottle caps.

For the customer, equipment delivery was not the end, but the beginning of another learning curve. Before formal mass production, injection parameter settings, mold temperature control, and tamper-evident band processing conditions all required repeated verification and optimization.

Through systematic on-site machine setup and operator training, the customer gradually established its own standard operating procedures for bottle cap injection molding, including:

- Stable setting of injection and holding pressure curves

- Multi-cavity mold filling balance adjustment logic

- Tamper-evident band cutting and folding quality inspection standards

- Mold cleaning and routine maintenance checkpoints

When this knowledge was truly internalized as team capability, the customer could quickly adjust processes even when facing different bottleneck specifications or material changes, rather than starting from scratch.

After the production line officially began operation, the most noticeable change was not a single data point, but an overall improvement in operational rhythm.

In terms of cost, in-house bottle cap production effectively reduced transportation and inventory pressure and allowed output to be adjusted in real time according to order demand. In terms of quality, bottle cap sealing performance and tamper-evident band consistency were significantly improved. In terms of production flexibility, multi-specification changeovers no longer caused long downtime, and production line utilization was greatly increased.

More importantly, the customer was no longer passively waiting for supply, but truly mastered the core capabilities of bottle cap injection molding.

Looking back on this implementation experience, the customer's greatest gain was not just a bottle cap production line, but a set of process thinking that can be replicated and expanded. When equipment, molds, and downstream processing are integrated in a systematic manner, the production line is no longer just about solving current orders, but about reserving flexibility for future market changes.

For manufacturers preparing to invest in or upgrade bottle cap injection molding, what truly deserves attention is not just injection machine specifications, but whether the entire production line can continuously maintain quality and efficiency during long-term operation.

Moving from outsourcing dependence to in-house mass production is not an easy path, but it allows the customer to regain control over product quality, delivery schedules, and market responsiveness. Bottle caps may seem small, but they are the first line of defense for brand trust and packaging quality. When the injection molding process is truly stable, bottle caps are no longer just accessories, but a part of corporate competitiveness.

At Huarong, we not only provide injection molding machines, but are also committed to helping customers build integrated solutions best suited to their production line needs. From planning to implementation, from machine setup to mass production, from operation to management, we are your best partner on the path toward smart manufacturing and sustainable competitiveness.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/