Thick-Wall Molding Technology:Designed for High-Structural Injection Requirements

2025-12-18 14:14:02

Thick-wall injection molding refers to a molding approach in which the wall thickness is significantly greater than that of general injection-molded parts. It is suitable for large load-bearing structures, housing support components, and functional thick-wall structural parts. Compared with thin-wall molding, the greatest challenges of thick-wall design include extended cooling time, increased flow resistance, internal stress management, and process stability. Most modern industries must strike a balance between design and equipment to ensure mass-production yield and machine efficiency.

Thick-wall injection molding refers to a molding technology in which the part wall thickness is significantly greater than that of typical parts (usually greater than 3–4 mm). It is mainly used for plastic products that require high structural strength, load-bearing capability, impact resistance, or large structural components. Compared with thin-wall molding, thick-wall parts focus more on mechanical performance and dimensional stability rather than extreme lightweighting and rapid cycle times.

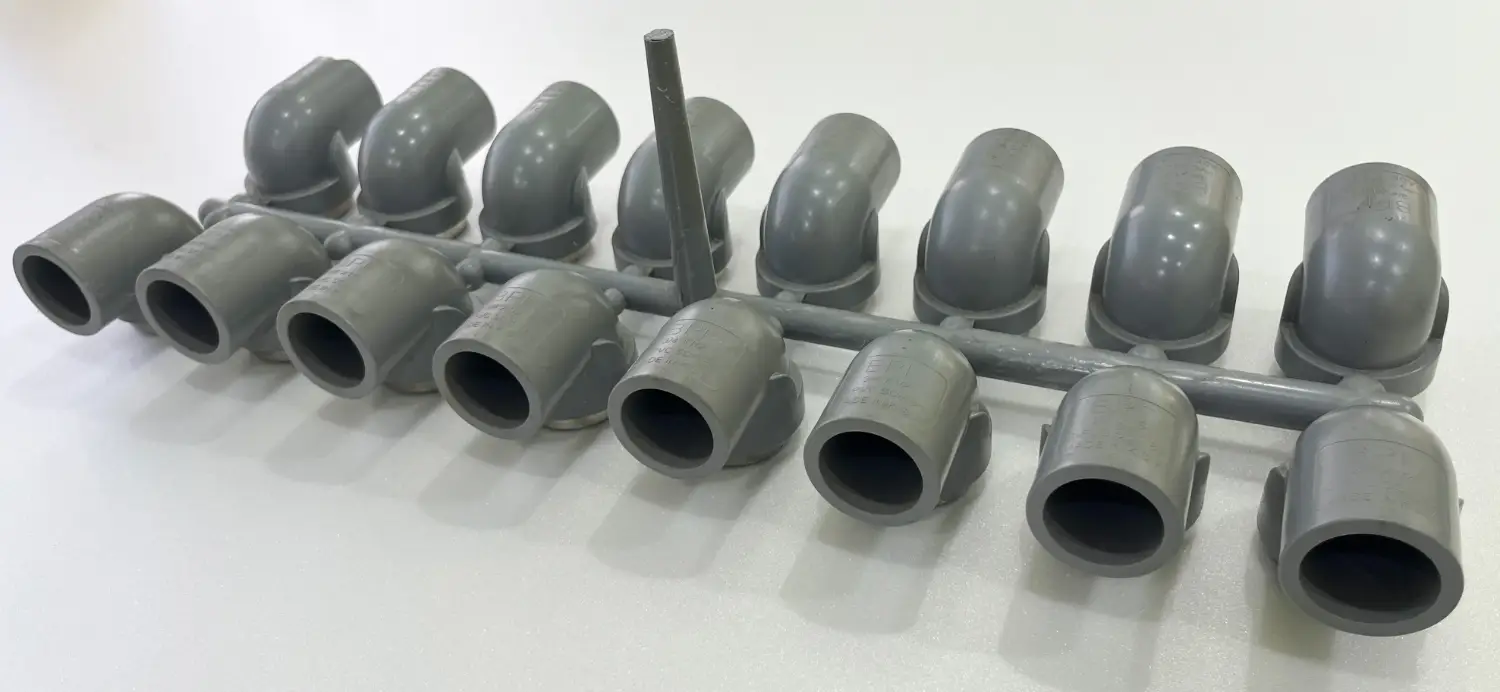

- Industrial equipment covers and structural support components

- Large containers and mechanical components

- Automotive interior and exterior structural parts

- Functional accessories for durable products

The core of thick-wall injection molding lies in coordinating structural design with molding parameters, allowing thicker material cross-sections to be smoothly filled, cooled, and solidified in the molten state without causing product deformation or insufficient strength.

Thick-wall parts inherently provide better impact resistance, load-bearing capacity, and rigidity than thin-wall parts, making them more favorable for mechanical structural components and parts subjected to pressure loads (such as support columns and frames). Due to their greater wall thickness and material volume, thick-wall parts exhibit better resistance to deformation and mechanical fatigue compared to thin-wall parts.

One of the greatest challenges of thick-wall molding is the significant extension of cooling time. Thicker cross-sections require more time for heat dissipation, directly increasing the duration of each cycle. This is the most evident difference between thick-wall and thin-wall molding in terms of production efficiency.

※ In general injection molding, cooling may account for 50–80% of the total molding cycle, while for thick-wall parts, this proportion is even higher due to larger material volume.

The greater the wall thickness, the higher the flow resistance of the molten material within the mold cavity. This requires more precise control of injection pressure, injection speed, plasticizing temperature, and mold temperature to ensure that the molten plastic fills complex geometries within an appropriate time frame.

| Characteristic Comparison | Thick-Wall Injection Molding | Thin-Wall Injection Molding |

| Typical Wall Thickness Range | > 3 mm | < 1.5 mm |

| Primary Design Focus | Structural strength, mechanical performance | Lightweighting, rapid cycles |

| Cooling Time Impact | Significantly extended | Rapid cooling, short cycles |

| Molding Equipment Requirements | Emphasis on stable filling and holding pressure | High pressure and high-speed injection |

| Applicable Material Range | Broad (structural materials, engineering plastics, etc.) | High-flow materials required |

There are significant differences in design strategies between thick-wall and thin-wall parts. Thick-wall parts prioritize structural robustness and mechanical performance, whereas thin-wall parts emphasize lightweighting and rapid turnover.

Thick-wall parts typically require higher injection pressures and clamping forces to overcome material flow resistance and ensure complete cavity filling. Unlike thin-wall high-speed machines that pursue extremely high speed and pressure switching, thick-wall machines must provide high-torque screw plasticizing and stable injection capability to ensure uniform filling of molten material over longer flow lengths and larger cross-sections.

Cooling time for thick-wall parts is longer than that for thin-wall parts; therefore, the performance of machine and mold cooling systems is critical. Well-designed cooling circuits and mold temperature control can shorten cycle times, improve dimensional stability, and are key factors in enhancing production efficiency for thick-wall parts.

In the functional design of thick-wall injection machines, the following points are critical for improving molding stability and efficiency:

High-performance servo control enables precise control of injection speed and pressure curves, stabilizing molten material flow during the filling stage and preventing excessive internal stress or uneven filling in thick-wall parts caused by pressure fluctuations.

Thick-wall parts require relatively large plasticizing volumes. Screw diameter and compression ratio design are crucial for uniform plasticization and stable injection. A well-designed screw structure can improve melt homogeneity and reduce material shear degradation.

Thick-wall parts generate higher internal pressure; therefore, the rigidity of the clamping unit, tie bars, and platens must be optimized to prevent structural deformation of the machine under high injection pressure, which could affect dimensional stability. This is particularly important for thick-wall parts.

Cooling time usually dominates the entire process cycle for thick-wall parts. Consequently, machines and molds should be equipped with multi-zone independent mold temperature control and high-efficiency cooling circuits to reduce heat accumulation and improve cycle efficiency.

Thick-wall machines place greater emphasis on stability and material control, rather than the extremely high pressure and high speed required by thin-wall high-speed machines. The focus is on long-term process stability and repeatability.

| Characteristic Comparison | Thick-Wall Injection Machine | Thin-Wall High-Speed Injection Machine |

| Primary Focus | Stable filling, material pressure control | Extremely high injection speed and cooling efficiency |

| Injection Pressure Requirement | Medium to high | Extremely high |

| Injection Speed | Moderate | Primarily high speed |

| Cooling Strategy | Multi-zone precise control, long cycles | Rapid cycles, short cooling |

| Equipment Reinforcement Focus | Clamping rigidity, improved plasticizing efficiency | High-pressure servo response and pressure switching |

With the intelligent transformation of manufacturing, such as smart automation, MES system integration, and predictive maintenance, further integrated into injection molding production lines, thick-wall injection machines offer the following upgrade directions:

By collecting pressure, temperature, and torque data through sensors and combining them with AI analysis models, potential deviations can be detected in advance, making thick-wall processes more stable and effectively reducing downtime and scrap rates.

Machine interfaces can be integrated with MES or automated scheduling systems, enabling higher traceability and process transparency in thick-wall part production and improving cross-departmental collaboration efficiency.

By integrating flow simulation with actual machine scheduling, thick-wall designs can be validated in advance for suitability with machine parameter settings, enabling digital twin implementation and shortening mold validation time.

Thick-wall injection molding is a technical challenge positioned between high structural requirements and precision processing. It involves not only wall thickness design concepts but also requires a high level of coordination among equipment, molds, and materials. Understanding the technical characteristics of thick-wall molding and selecting appropriate machine configurations and process controls are the core factors for achieving mass production of high-quality, large-sized, and high-performance plastic parts.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/