Thin-Wall Injection Molding: Key Technology for Efficient and Lightweight Manufacturing

2025-11-13 13:04:27

As the demand for lightweight, high-precision, and high-performance plastic components continues to rise in the medical, automotive, electronics, and packaging industries, thin-wall injection molding has become a vital technology in modern manufacturing. It not only reduces part weight and material costs but also shortens cycle times and enhances environmental benefits.

Thin-wall injection molding is a specialized technique used to produce plastic parts with wall thicknesses lower than conventional designs. Typically, parts with wall thicknesses less than 1 mm are considered thin-walled; for larger parts, wall thickness can range from 2–4 mm. Compared to traditional injection molding, thin-wall molding enables the production of lighter, thinner, and structurally sound parts while improving manufacturing efficiency.

| Advantage | Description |

| Weight Reduction & Cost Saving | Thin-wall designs use less material, lowering raw material and transportation costs — ideal for electronics, automotive, and packaging industries. |

| High Production Efficiency | Thin-walls cool faster, reducing cycle times by 30–50%, increasing overall productivity. |

| Greater Design Flexibility | Enables micro and complex geometries that balance functionality and aesthetics. |

| Environmental Benefits | Reduced material usage and shorter cycles lower energy consumption and carbon emissions. |

A successful thin-wall design must ensure structural integrity, smooth mold filling, and easy demolding. Poor design can lead to defects such as short shots, warpage, sink marks, or flash.

Uneven wall thickness is one of the most common issues in thin-wall parts. Designers should maintain uniform thickness and avoid sudden transitions.

- Recommended minimum thickness:0.9 mm

- Add ribs or stiffeners for reinforcement when necessary

- Prevent material stagnation and incomplete filling

Ribs enhance rigidity but must be properly designed to avoid defects:

- Rib thickness ≤ 60% of wall thickness (equal to wall thickness if < 1 mm)

- Rib spacing ≥ 3 × wall thickness

- Rib root radius < 0.5 × wall thickness; draft angle ≥ 1°

- Cross ribs can be added for additional support

Sharp corners may cause flow hesitation or warpage. Rounded corners are recommended:

- Smooth internal and external corners improve flow

- Larger draft angles aid in part ejection

Thin-wall parts require high injection speed and pressure. Gate design should prevent blockage and shear:

- Gate size should be larger than the part's wall thickness

- Use hot runners or edge gates for better filling performance

- Add a gate well to reduce stress concentration if the gate junction is sharp

Thin-wall molding demands materials with high flowability. Choosing the right material is critical.

| Material | Flowability | Typical Applications | Notes |

| HDPE | High | Food containers, thin-wall structures | Avoid degradation under high shear rates |

| LDPE | High | Packaging films, containers | Low melting point, temperature control required |

| PP | Medium | Packaging, automotive parts | High flow versions may require shrinkage control |

| PA | Medium-Low | Precision parts | Hygroscopic, requires drying to prevent deformation |

| PC | Low | Optical components | Difficult to fill thin-walls |

| LSR | High | Medical devices | Prone to flashing, requires precision molds |

Thin-wall molding requires precise control over injection speed, injection pressure, and mold temperature to ensure part integrity.

1. Material Heating and Softening:Plastic or LSR is heated to a moldable state.

2. High-Speed Injection:Ensures complete filling before premature solidification.

3. Cooling and Solidification:Rapid cooling and uniform mold temperature are essential.

4. Demolding and Trimming:Proper draft angles, ejector pins, and gate design ensure clean release.

- Rotational Molding:Thickness 0.05–0.25 mm; provides even coating for small parts.

- Vacuum Forming:Thickness 0.05–0.25 mm; low-cost tooling, lower precision.

- Thermoforming:Heated material is pressed into shape, ideal for specific geometries and thicknesses.

- Regular mold maintenance:Clean cavities and vents.

- Equipment monitoring:Maintain stable pressure, temperature, and speed.

- Operator training:Understand thin-wall part behavior and machine operation.

- Precision inspection:Regularly calibrate mold accuracy and cooling systems.

| Defect | Cause | Countermeasure |

| Short Shot | Incomplete filling | Increase injection pressure, adjust gate size or position |

| Warpage | Uneven cooling | Optimize cooling channels, balance mold temperature |

| Sink Marks | Uneven wall thickness | Maintain uniform thickness, add supporting ribs |

| Flash | Poor mold alignment or insufficient clamping force | Check mold alignment and clamping system |

| Weak Weld Lines | Unbalanced flow front | Improve rib design, lower injection speed |

| Dimensional Deviation | Poor tolerance design | Validate prototype and conduct dimensional testing |

Thin-wall molding is widely used across industries for its balance of precision, lightweight design, and cost efficiency:

- Medical Devices:Syringes, catheters, surgical tools ( thickness as low as 0.1–0.3 mm )

- Consumer Electronics:Mobile phones, laptops, camera housings with lightweight precision shells

- Automotive Components:Engine covers, interior trims, reducing vehicle weight, and fuel consumption

- Food Packaging:Lightweight containers, caps, and sterile packaging for improved logistics and material savings

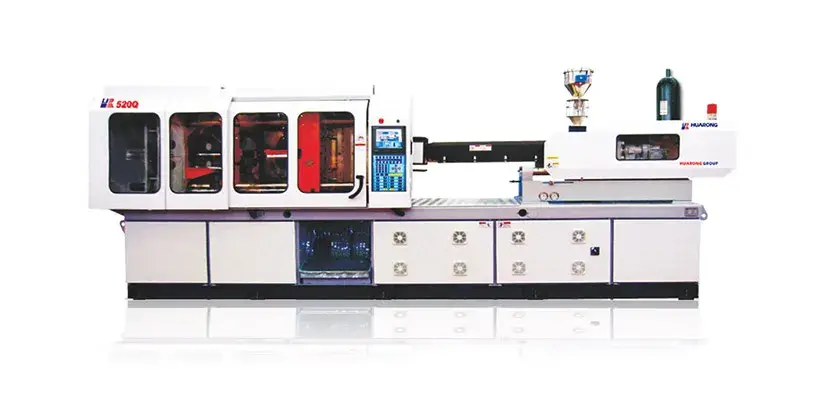

Huarong's High-Speed Thin Wall Injection Series is engineered to meet the demanding requirements of thin-wall molding, delivering powerful injection performance and structural stability—ideal for the medical, packaging, and electronics industries.

- High-Speed Precision Injection & Strong Plasticizing Capability:

Equipped with a high-response servo control system to ensure stable melt delivery and precise pressure control. - Reinforced Structure Design:

Enlarged tie bars and thickened platens with stress analysis and 3D structural reinforcement enhance durability by 20%, ensuring long-term stability. - High-Speed Injection Unit:

Proprietary high-speed injection system combines rigidity and durability, achieving ultra-fast filling times. - ACC Accumulator System with Servo Valve Control:

The servo valve works in tandem with the accumulator to deliver high-pressure oil with lightning-fast response, dramatically improving injection speed and consistency.

Thin-wall injection molding is a key competitive technology in modern manufacturing. It enables significant reductions in part weight, material consumption, and cycle time while maintaining structural integrity and precision. Although technically demanding, thin-wall molding delivers outstanding benefits when properly designed, managed, and operated.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/