From Taiwan to Thailand — Expanding Global Manufacturing Power with Huarong

2025-11-06 10:54:35

As home appliances evolve toward lighter, sleeker, and more frequently updated designs, maintaining consistent product quality with energy-efficient and stable injection molding equipment has become a crucial factor in competitiveness.

This case study examines how a leading Taiwanese small home appliance brand successfully established a smart, automated production line in Thailand, utilizing Huarong’s servo energy-saving and two-platen injection molding machines. This approach enabled high-precision, high-efficiency, and flexible mass production capabilities, driving its international expansion.

Known for its “high cost performance × stable quality” positioning, this brand has long been rooted in the Taiwan market while actively expanding into emerging regions such as Southeast Asia, Japan, Korea, and the Middle East, gradually forming a transnational supply network.

Its product portfolio spans home cleaning, seasonal appliances, and kitchen electronics, all of which demand exceptional precision, surface finish, and durability from plastic components.

Products such as steam mops, multifunctional cleaners, and dehumidifiers typically use engineering plastics like ABS and PC, which must retain rigidity and gloss under high-pressure molding conditions.

By adopting servo energy-saving injection molding machines, the customer maintains injection pressure precision within ±0.3%, ensuring consistent molding quality and eliminating short shots or burrs.

Recommended model: Servo Injection Molding Machines – HRS & HRFC Series

For DC inverter fans, circulation fans, and energy-saving heaters, the structural designs are usually larger and uneven in wall thickness. The molding process therefore requires stable holding pressure and uniform cooling to prevent warpage, sink marks, and surface ripples.

Appliances such as air fryers, electric kettles, and blenders demand both a glossy, color-consistent exterior and food-grade heat-resistant interior parts.

By introducing injection molding machines equipped with closed-loop temperature control and multi-stage injection pressure systems, the customer achieves stable melt filling, smooth surfaces, and reduced bubbles or flow marks — ensuring both safety and visual appeal.

The brand has recently expanded into personal grooming and compact electronics, such as hair dryers, handheld vacuum cleaners, and mite removers.

These products feature complex geometries and variable wall thicknesses, requiring high-speed, precise control.

By integrating high-response servo injection systems with three-axis take-out robots, the factory enables fast, stable demolding, reducing manual intervention while ensuring excellent appearance and dimensional accuracy.

Recommended model: Telescopic and Single Arm – HRB-LW Series

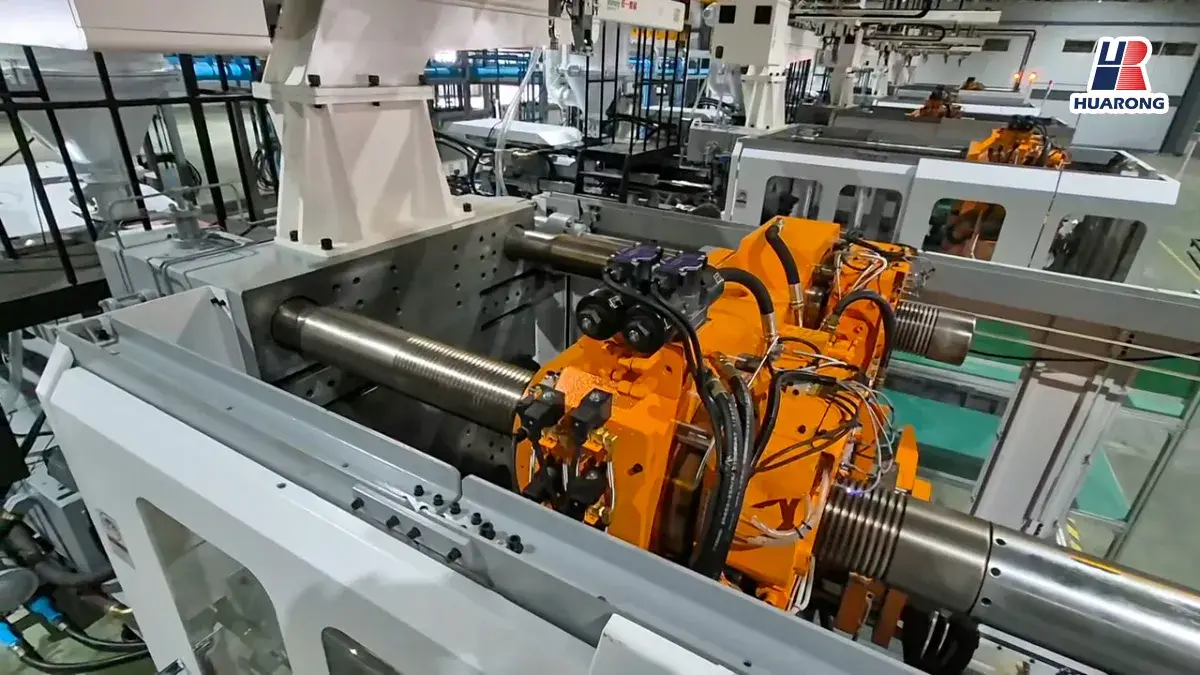

To meet the dual demands of quality, stability, and rapid changeover, the customer deployed multiple Huarong high-performance servo injection molding machines, including several two platen injection macjhins.

Each system integrates robotic automation, quick mold change modules, and intelligent inspection systems, building a flexible and efficient molding platform.

The NRH Two-Platen Series features a compact footprint and extended opening stroke, ideal for factories with limited space or diverse mold dimensions.

Its patented Tie-Bar Release Mechanism (Patent No. M481124) allows the upper tie-bar to detach, greatly improving mold installation convenience and space utilization, while reducing mold change time and area requirements.

With closed-loop pressure and velocity control, the machines automatically adjust the injection curve in real time.

Even with variations in resin batches or mold temperature, product weight deviation remains within ±0.1 g, preventing short shots, flash, or dimensional deviations.

The high-rigidity platen design and linear guide rails ensure consistent clamping force during high-pressure molding, enhancing surface gloss and uniformity, making them ideal for visible home appliance components such as hair dryers, fans, and vacuum housings.

For multi-product and small-batch production, the Quick Mold Change (QMC) system combines hydraulic clamping, positioning pillars, and smart parameter recall, enabling mold changes in 15–20 minutes while automatically restoring process settings, ensuring rapid production recovery.

Meanwhile, the integration of three-axis robots, conveyors, and stacking devices forms a fully automated injection line.

From molding and take-out to cooling, inspection, and packaging, the system minimizes human intervention, reduces error rates, and enhances productivity and operational safety.

In terms of energy-saving injection molding, the injection molding machine is equipped with a servo-driven energy-efficient system that automatically adjusts power output across the injection, holding, and cooling stages. Compared with conventional hydraulic machines, it reduces power consumption by 50%–70%, helping customers achieve both ESG-oriented sustainable manufacturing and lower operational costs.

1. Closed-Loop Precision Control for Consistent Quality

- Pressure and speed fully closed-loop controlled; part weight deviation < ±0.1 g

- Rigid platen + linear guide design reduces mold shift and deformation

2. Quick Mold Change System for High Mix-Low Volume Production

- Equipped with Quick Mold Change (QMC) system

- Mold change time within 15–20 minutes, ideal for flexible scheduling

3. Automated Take-Out and Stacking for Labor Reduction

- Integration of three- or five-axis servo robots for automatic take-out/classification

- Built-in anti-clamping safety coordination and cycle synchronization

4. Smart Energy Management Supporting Sustainable Manufacturing

- Servo-driven energy recovery module reduces power consumption by 50–70%

- Significant reduction in yearly electricity cost per machine

5. Smart Factory Integration and Remote Monitoring

- Compatible with MES/HFM systems for OEE, energy, and mold life monitoring

- Data visualization enables cross-site management and process optimization

Recommended model: Smart Factory Management - HFM

In this Thailand project, the main production equipment selected was the Huarong NRH Two-Platen Injection Molding Machine, designed for medium to large plastic parts such as appliance housings, logistics containers, structural parts, and automotive components.

With shorter machine length and longer opening stroke, the NRH series balances high efficiency with optimized space utilization.

The NRH lineup integrates several patented technologies and smart control modules, including:

- Injection Positioning Device (Patent No. M636571): Ensures precise platen alignment for faster machine setup.

- Tie-Bar Release Mechanism (Patent No. M481124): Enables upper tie-bar removal for convenient mold hanging and layout flexibility.

- Floating Tie-Bar Bearing Module (Patent No. M634662): Supports heavy loads while maintaining long-term structural precision.

- Internal Sliding Foot Module (Patent No. M578643): Provides self-alignment and structural rigidity for stable performance.

- Optimized Hydraulic System: Dual nuts with synchronized hydraulic control ensure uniform clamping pressure and reduce mold wear.

- Intelligent Monitoring & Lubrication System: Continuously tracks temperature and lubrication, preventing overheating or oil shortage, while performing auto-lubrication.

These innovations make the NRH series a top choice for manufacturers upgrading to high-efficiency production of large components, offering exceptional precision, reliability, and maintainability.

Recommended model: Two platen injection molding machine – NRH series

By installing multiple Huarong servo machines and full automation lines in its new Thailand factory, the customer achieved remarkable gains in productivity and stability.

The facility is spacious and brightly lit, featuring centralized material feeding and temperature control, which enhances layout order and scheduling flexibility.

Measured results show an average molding cycle time of 24.5 seconds, yield rate of 99.6%, and productivity increase of over 15%.

With the smart manufacturing monitoring platform, the management team can track OEE, energy use, and mold lifespan in real time, ensuring efficient cross-border factory management.

Machines maintained stable performance during long continuous operation, with maintenance intervals exceeding 6,000 hours, minimizing downtime.

Combined with remote diagnostics and local spare-part service, the Thailand facility operates smoothly with uninterrupted delivery performance.

Walking into the customer’s Thailand facility, one immediately notices the well-organized production space, clear workflows, and robotic arms operating in perfect rhythm.

With stable and efficient equipment as the foundation, the customer achieves peace of mind knowing that even overseas production remains consistent, reliable, and on schedule.

The brand’s success in expanding internationally lies not only in design and marketing strategies, but also in choosing reliable injection molding machines as the backbone of its manufacturing excellence.

From shorter cycles and lower energy consumption to exceptional quality stability, every indicator proves the importance of machine performance in achieving production transformation.

If your factory is considering upgrading or automating, Huarong is ready to help you plan the optimal injection molding solution — whether it’s a single machine installation, full-plant automation, or overseas expansion — with comprehensive technical support and localized service.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Energy Saving Injection Molding: The Key to Lower Costs, Higher Productivity, and ESG Readiness

- Home Appliance Manufacturing Company with Huarong Machine

- Beyond Injection Molding! Analyzing Successful Transformation Through Turn-Key Automation Solutions