Bakelite Injection Molding: Guide to a High-Performance Thermoset Process

2025-08-06 13:04:27

Bakelite injection molding is a highly specialized manufacturing process engineered to produce robust, heat-resistant, and electrically insulating components essential for modern industry. Unlike conventional thermoplastics that can be repeatedly melted and reformed, Bakelite (a phenolic resin) undergoes an irreversible chemical transformation. Think of it less like melting ice and more like baking a cake—once it's set, it's permanent. This guide provides a comprehensive roadmap for specifying, launching, and scaling your phenolic production with confidence.

Understanding Bakelite begins with its identity as a thermoset material used in injection molding. This core characteristic is what gives it a competitive edge in demanding environments where other plastics would fail.

Further reading: Thermoset Injection Molding: Process, Benefits & Applications

When correctly processed through Bakelite injection molding, the resulting components deliver an unmatched combination of properties:

- Exceptional Heat Resistance: Bakelite maintains its structural integrity and dimensional stability at high temperatures, making it ideal for under-hood automotive parts and industrial switchgear.

- Superior Electrical Insulation: With high dielectric strength and arc resistance, it’s a go-to material for electrical connectors, insulators, terminal blocks, and electronic enclosures.

- Excellent Dimensional Stability: The cross-linked molecular structure results in minimal creep under load and predictable performance over time.

- High Rigidity and Hardness: Functional fillers like glass or mineral fibers create high-impact, rigid components for structural applications.

- Chemical Resistance: Bakelite stands up well against oils, greases, and many other chemicals.

We specify Bakelite wherever thermal stability and insulation are paramount:

- Automotive: Under-hood components, engine bay housings, and brake system parts.

- Electrical & Electronics: High-voltage switchgear, connectors, coil forms, and circuit breaker casings.

- Consumer Goods: Handles for cookware (pots and pans), appliance knobs, and decorative casings that require a durable, classic finish.

- Industrial: High-load knobs, pump housings, and terminal blocks.

Precise control of the curing reaction is the key to successful bakelite injection molding. The entire process involves preheating, injection, curing, cooling, and demolding — requiring high-performance machinery and precise mold design.

The process begins with phenolic material, typically a powder or granule. Moisture is the enemy, as it can cause voids and surface defects. Materials must be stored in sealed containers. The injection barrel is gently heated with circulating oil or water to a cool 70–90°C (160–195°F). This prevents the material from curing prematurely due to friction from the screw.

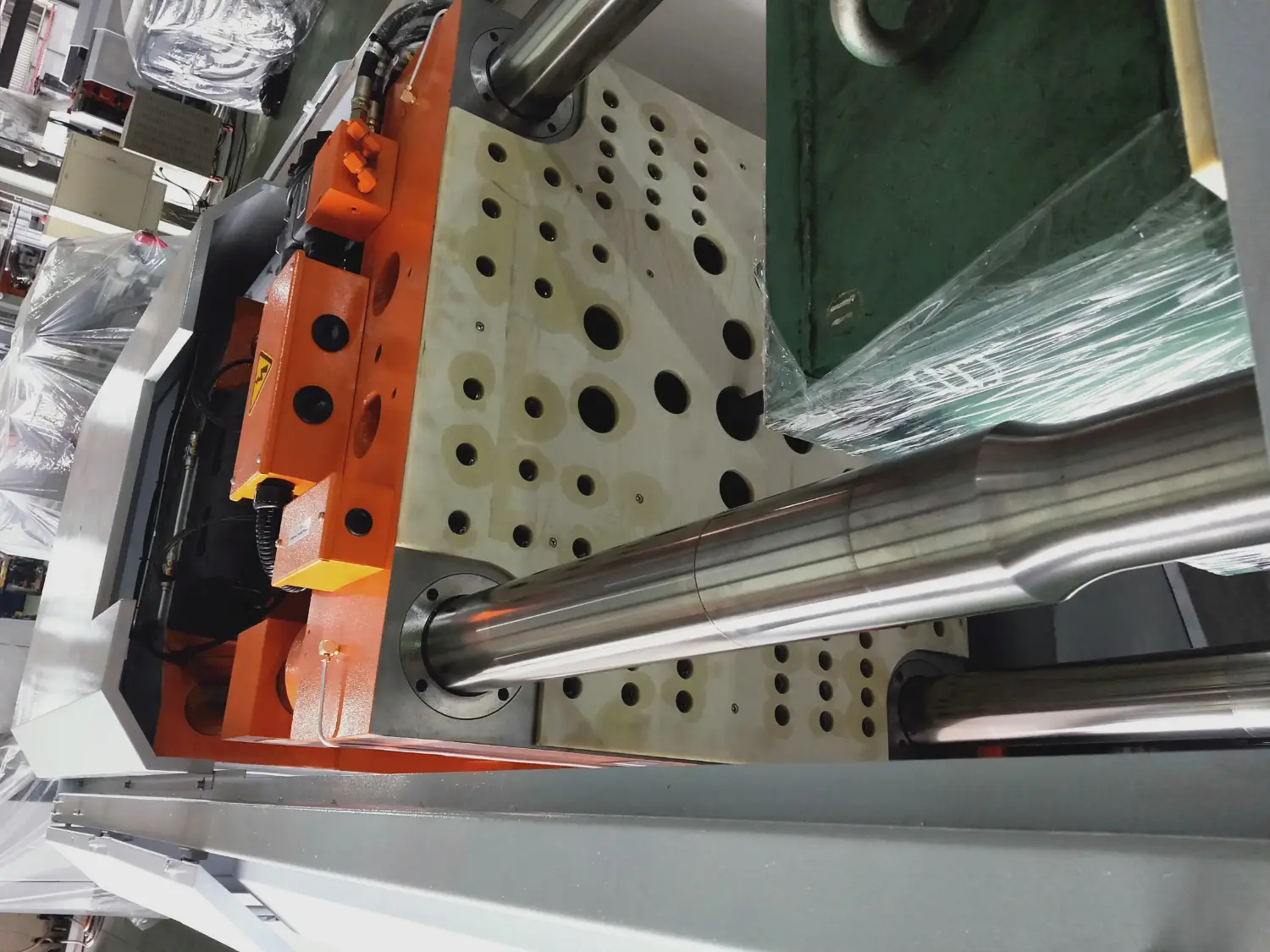

A specialized low-compression screw moves the material forward, transforming it into a homogenous, dough-like mass. This mass is then injected into the mold under high pressure. The injection speed is critical; too fast can scorch the material, while too slow can cause a short shot. A robust mold venting system is absolutely essential here to let moisture and volatile gases escape.

Once the cavity is filled, the chemical reaction begins. The mold is heated to a high temperature, typically 160–180°C (320–355°F), which catalyzes the thermosetting cross-linking. During this phase, a "degassing" or "breathing" cycle is often programmed—the mold opens by a fraction of a millimeter to release trapped gases before clamping shut again to complete the cure.

After curing (typically 30-90 seconds), the part is a hot, solid structure. Unlike common injection molding materials of thermoplastics, the part is ejected while still hot. Because cured Bakelite is rigid and brittle, the ejection system must be precisely balanced to remove the part without causing cracks. Many Bakelite parts require a post-processing step called de-flashing to remove the thin slivers of material (flash) that can form at the mold's parting line.

Extra reading: Thermoplastic Injection Molding Explained: How It Works & Why It’s Essential

Most defects in Bakelite injection molding can be traced back to imbalances in temperature, pressure, or venting. Here’s how we solve the most common challenges:

| Defect Type | Primary Causes | Recommended Engineering Solutions |

|---|---|---|

| Burn Marks/ Voids | Trapped gas from inadequate venting; excessive injection speed. |

|

| Weld Lines | Low mold temperature; insufficient pressure; poor gate location. |

|

| Demolding / Cracks | Incomplete curing; insufficient draft angles; unbalanced ejection force. |

|

| Flash | Excessive injection pressure overpowering clamp force; worn-out parting line. |

|

| Short Shots | Material curing before the cavity is full; insufficient pressure or speed. |

|

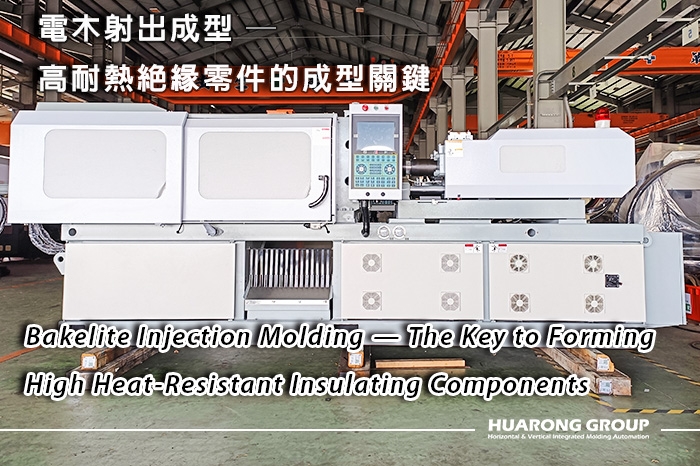

Success in Bakelite injection molding isn’t just about the process; it's about having a machine engineered to master it. The Huarong BL series is not a standard thermoplastic machine adapted for thermosets—it is a purpose-built solution, designed from decades of hands-on experience to overcome the specific challenges of phenolic molding.

Recommended Equipment: Thermosetting Bakelite Injection Machine - BL Series

Here’s how the BL series translates engineering features into higher yield, lower scrap, and reliable production for you:

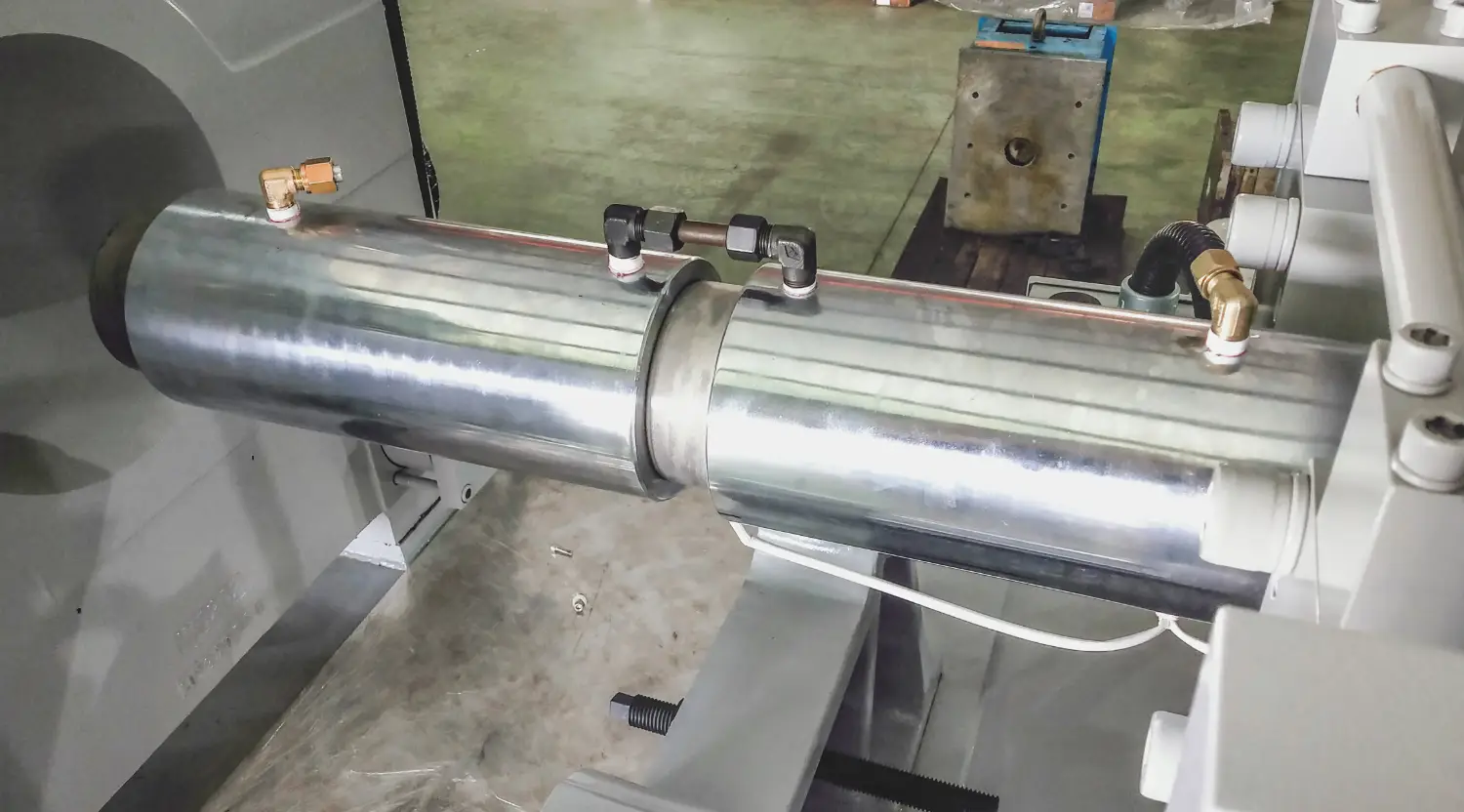

A standard screw will generate too much friction, causing premature curing and material degradation. Our solution is a specialized, low-compression, wear-resistant screw and barrel set.

- What this means for you: The material is plasticized gently and consistently without scorching. This preserves the material's integrity, prevents blockages, and ensures a stable shot volume every single cycle, which is the first step to eliminating defects.

Bakelite requires a cool barrel and a hot mold. Managing this temperature differential is critical. The BL series features a precision oil-circulated temperature control system for the barrel (maintaining 80-100°C) and a separate, high-power PID heating system for the mold (maintaining 160-180°C).

- What this means for you: You get precise, stable, and independent control over the two most critical temperature zones. This prevents premature curing in the barrel while ensuring complete and uniform curing in the mold, leading to dimensionally accurate parts with excellent mechanical properties.

Heat from the 180°C mold can easily transfer to the machine platens, causing energy loss and thermal instability. We integrate high-performance thermal insulation plates between the mold and the machine platens.

- What this means for you: Energy is focused where it's needed—in the mold—leading to faster cycle times and significant energy savings. It also protects the machine's structural integrity and hydraulic systems from heat damage, ensuring long-term reliability.

The primary difference is the process type. Regular plastic (thermoplastic) molding involves melting plastic pellets and cooling them in a mold to solidify. Bakelite injection molding is a thermoset process that uses a chemical reaction triggered by heat inside a hot mold to permanently harden the part. As a result, the mold is hot (160-180°C), while for thermoplastics, the mold is cool.

Because Bakelite is a thermoset plastic, its transformation is irreversible. Once cured, it cannot be melted down and reused. This means any scrap material—including runners, sprues, and defective parts—is a 100% material and cost loss. This makes minimizing the defect rate with a precise machine critically important for profitability.

It is strongly discouraged and generally not feasible. A standard machine is designed to heat the barrel and cool the mold, the exact opposite of what Bakelite requires. Using it would lead to premature material curing in the barrel, blockages, poor part quality, and potential damage to the screw and barrel. A dedicated thermoset machine like the Huarong BL series is essential.

It is extremely important. The chemical curing process of Bakelite releases a significant amount of volatile gas and moisture. Without adequate and correctly placed vents in the mold, this gas becomes trapped, leading to severe defects like burn marks, voids (air bubbles), and weak weld lines, compromising both the appearance and structural integrity of the part.

Bakelite injection molding remains an indispensable process for industries that depend on superior heat resistance and electrical insulation. Success is not accidental; it is the result of deep material knowledge, meticulous process control, and the selection of correctly engineered machinery.

With the right expertise and equipment like the Huarong BL thermosetting injection molding machine, the unique challenges of phenolics become your competitive advantage. If your application demands the ultimate in thermal performance and structural integrity, contact our team today for expert support and a customized equipment strategy.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/