Injection Speed in Injection Molding: Master’s Guide to Quality and Productivity

2025-07-24 10:32:10

In injection molding, the injection speed has a critical influence on part quality, surface finish, dimensional accuracy, and overall production efficiency. Think of it like filling a glass: pour too quickly and you spill; too slowly and it takes too long. Similarly, for molten plastic, injection speed governs how well the mold is filled and impacts whether the finished part is flawless or defective.

Injection speed refers to the rate at which the screw advances to push molten plastic into the mold cavity, typically expressed in mm/s or cm³/s. It dictates how quickly the melt front advances, directly affecting the balance between cavity pressure, shear heating, and cooling time.

Its control affects:

- Melt flow behavior — how smoothly the injection molding material moves through the cavity.

- Cavity pressure and venting — avoiding burn marks or short shots.

- Shear heating — preventing overheating or material degradation.

Injection speed is especially important for:

- Thin-wall parts — like food containers or electronic casings that freeze quickly.

- Complex geometries — long flow paths or multiple ribs need proper speed staging.

- High-appearance parts — transparent lenses, glossy panels, or smooth finishes.

- Weld line risk areas — where multiple melt fronts meet.

Excessively high injection speed can create excessive shear heat and unstable flow, leading to:

- Burn marks from trapped air ignition due to poor venting.

- Jetting from high-speed melt spurting into open space before adhering to cavity walls.

- Flash from high-pressure overpacking, especially at parting lines or vents.

Speeds that are too low often result in incomplete filling and surface flaws:

- Short shots due to premature cooling or insufficient melt momentum.

- Poor weld lines as melt fronts cool before merging, reducing bond strength.

- Cold slugs and surface flow marks from unstable melt flow.

Injection speed affects multiple aspects of the molding process, from flow dynamics to production efficiency.

Speed influences the melt’s flow pattern—controlled speeds promote laminar flow, resulting in a smoother surface, while incorrect speeds can cause turbulence that leads to visible flow lines or rough textures. Keeping the appropriate melt-front velocity is essential for achieving high-gloss finishes and precise detail reproduction.

Injection speed influences both immediate cavity pressure and heat retention. Using low speeds may result in incomplete packing, causing sink marks, voids, or warping. Conversely, very high speeds can raise local temperatures excessively, disrupting molecular alignment and leading to dimensional inaccuracies.

Using appropriate high-speed injection can decrease both fill time and overall cycle time. However, setting the speed incorrectly may lead to higher scrap rates, more frequent mold maintenance, and reduced mold lifespan. Implementing optimized multi-stage speed profiles helps maintain productivity while preserving part quality.

On the shop floor, a master doesn’t just look at numbers — they read the parts and the process:

- Watch the Gate Area

- Too fast: wavy flow marks or silver streaks.

- Too slow: frosty or dull surfaces near weld lines.

- Monitor the Pressure Curve

- Sharp spikes or drops suggest venting problems or poor speed stage switching.

- Run Short Shot Tests

- Partial fills at different speeds show how the melt front travels.

- Helps confirm the right V/P switchover timing.

Different parts of the mold need different speeds:

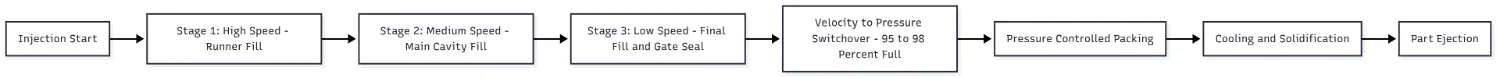

| Injection Stage | Suggested Speed | Purpose |

|---|---|---|

| Initial Fill (Sprue to Runner) | High | Quickly fill runners and avoid cold slugs |

| Middle Fill (Main Cavity) | Medium | Maintain smooth flow and surface finish |

| Final Fill (Near Full) | Low | Prevent pressure spikes, flash, and excessive holding pressure |

Further reading:Key Role of Holding Pressure:Enhancing Yield and Stable Mass Production

Different materials behave differently. Proper speed settings help avoid defects:

| Material | Recommended Speed | Notes |

|---|---|---|

| PP, PE | Medium–High | Good flow, avoid overheating |

| ABS, SAN | Medium | Prevent gas streaks, surface defects |

| PC, PMMA | Medium–Low | Reduce shear, keep optical clarity |

| PA (Nylon) | Medium–High | Moisture-sensitive, fill quickly |

| PBT, PET | High (Thin-Wall) | Fast cooling, prevent short shots |

Scientific molding integrates data-driven adjustments:

- Velocity to Pressure (V/P) Switchover should occur at 95–98% cavity fill, transitioning from velocity control to pressure control.

- Monitor cavity pressure profiles to confirm smooth transitions without overshoot.

- Verify part weight consistency over multiple cycles as confirmation of stability.

Injection speed refers to how fast the screw pushes molten plastic into the mold cavity. It is usually measured in mm/s or cm³/s. Correct injection speed ensures the melt fills the mold smoothly, prevents defects like short shots or burn marks, and maintains part quality.

Signs of excessive injection speed include:

- Burn marks caused by trapped air overheating.

- Jetting or snake-like patterns on the surface.

- Flash along parting lines due to excessive holding pressure.

Reducing initial fill speed or optimizing stage transitions can solve these problems.

If injection speed is too low, you might see:

- Short shots (incomplete filling).

- Weak weld lines that break under stress.

- Frosty, dull surface finish.

Increasing initial or mid-stage speed usually helps ensure proper fill.

Multi-stage control is essential for:

- Thin-wall parts that need high initial speed to avoid freeze-off.

- Complex molds with long flow paths to maintain consistent fill.

- High-appearance parts to avoid surface defects by slowing speed near the end of fill.

Injection speed controls how fast the mold fills, while injection pressure ensures the cavity is fully holded.

- Higher speed usually requires higher pressure to overcome flow resistance.

- Lower speed needs less pressure but risks incomplete filling.

Balancing both is critical for dimensional stability and mold protection.

While injection speed might seem like a straightforward numerical setting, it significantly influences flow behavior, surface finish, dimensional stability, and cycle efficiency. Implementing multi-stage speed control, customized to mold geometry and product needs, is crucial for consistent, high-quality outcomes. By coordinating injection speed with pressure, mold design, and real-time process feedback, manufacturers can improve part consistency, reduce cycle times, and prolong mold lifespan — making injection speed a key strategic factor for quality and productivity.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/