Injection Molding Cycle Time: The Key to Faster and Smarter Manufacturing

2025-04-25 11:43:53

Injection molding cycle time is one of the most crucial metrics in plastic manufacturing. It directly affects your production efficiency, the cost per part, and even the longevity of your equipment. In this article, we will delve into the meaning of cycle time, the factors that influence it, and proven strategies to optimize it for your molding operations.

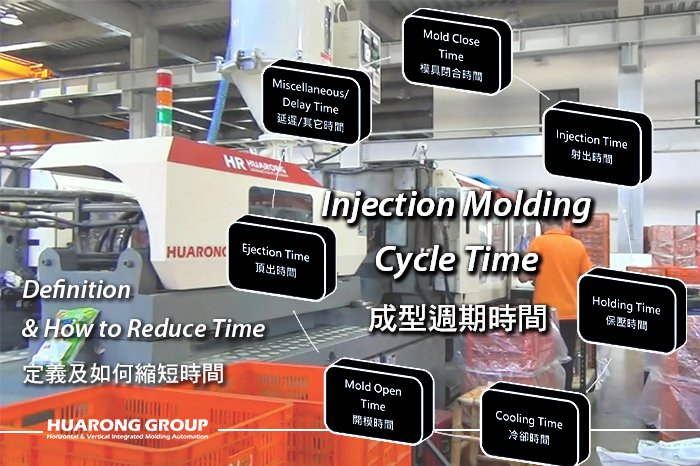

The injection molding cycle time refers to the total time taken to complete one full production cycle of a molded part—from mold closing to part ejection and mold opening again.

- Mold Close Time: This is the time during which the mold closes and locks under pressure.

- Injection Time: Molten plastic is injected into the mold cavity through the nozzle. Duration depends on shot size, injection speed, and mold flow resistance.

- Holding Time: This stage maintains mold pressure to compensate for shrinkage as the plastic cools, ensuring full cavity fill and preventing defects such as sink marks and voids.

- Cooling Time: The most time-consuming phase is when molten plastic solidifies in the mold.

- Mold Open Time: After cooling, the mold opens to eject the part.

- Ejection Time: This refers to the time required to eject the molded part using ejector pins or a robotic arm. If the part sticks or if multiple strokes are needed, this time increases

- Delay Time / Miscellaneous Time: This covers any other programmed or unplanned time between steps, such as:

- Safety interlocks and signal checks

- Robot movement or conveyor belt delays

- Manual interventions (if applicable)

- Machine response lag due to hydraulic delay or control system latency

The shorter your cycle time, the more parts you produce per hour—this directly impacts:

- Production Capacity

- Cost per Part

- Order Fulfillment Speed

- Machine Utilization Rate

Example:

- 30s cycle = 120 shots/hour

- 25s cycle = 144 shots/hour ➜ +20% Efficiency

Even a 2-second reduction in a high-volume operation can lead to substantial output increases.

This question is among the most commonly asked in injection molding. Reducing cycle time cannot depend solely on machine speed. It is crucial to simultaneously integrate "mold", "machine", "finished product design", "process control", and "automation system", addressing each aspect simultaneously. Here are some suggested directions for reference:

Also known as: Simultaneous Plasticizing During Mold Opening

Screw Fly technology enables the screw to start plasticizing (material preparation) while the mold is still opening, rather than waiting for the mold to fully open. This is particularly effective when the plasticizing time is longer than the cooling time, preventing wasted idle time after mold opening.

Core Condition: Screw Fly is only beneficial when plasticizing time > cooling time.

Benefits:

- Overlaps plasticizing and mold opening, improving time efficiency.

- Reduces machine idle time, enhancing overall cycle overlap.

- Shortens total cycle time by 10–20%.

- When combined with a direct-drive material storage motor system (like Huarong's design), it can achieve up to 26% energy savings.

Best suited for:

- Large products with long cooling times.

- High-output production demands.

- Machines equipped with independent plasticizing control systems.

Also known as: Simultaneous Ejection During Mold Opening

The Ejector Fly enables the ejection of the molded part to commence during mold opening, before the mold has fully separated. This technique requires the part structure and mold design to support safe early ejection without damaging the part or the mold.

Special Attention: Ejector Fly and Core Pull Fly cannot be activated simultaneously because ejection and core pull systems often share the same hydraulic circuit or solenoid valves.

Benefits:

- Overlaps ejection and mold opening actions, saving otherwise idle time.

- Speeds up the ejection process and shortens the overall molding cycle.

Best suited for:

- Standardized mass production.

- Parts with simple structures and no critical surface protection needs.

Notes:

- Must confirm that the part can be safely demolded early.

- Must predefine whether to prioritize Ejection Fly or Core Pull Fly based on circuit design.

Also known as: Simultaneous Core Retraction During Mold Opening

Core Pull Fly synchronizes core pulling (slider or lifter retraction) with the mold opening action. This eliminates the delay that usually occurs when waiting for core retraction after whole mold opening.

Special Attention: Ejector Fly and Core Pull Fly cannot run together if they share the same hydraulic circuits or valves.

Benefits:

- Core pull and mold opening proceed simultaneously, eliminating demolding delays.

- Further shortens overall molding cycle time and improves production efficiency.

Best suited for:

- Molds with sliders or core pulls.

- Parts that can safely disengage from the core early during mold opening.

Notes:

- Core pulling must be safely completed during the opening stroke to avoid mold jamming or damage.

- Requires careful hydraulic planning and motion logic during mold design.

| Configuration Type | Core Technology Description | Impact on Cycle Time | System Complexity | Best Applied For | Important Considerations |

|---|---|---|---|---|---|

| Screw Fly (Plasticizing During Mold Opening) | Screw starts plasticizing while mold is opening to avoid idle time | Shortens cycle by 10–20%; boosts energy efficiency with direct drive (up to 26%) | Low to Medium (requires shut-off nozzle and direct-drive motor for best effect) | Large products with long cooling time; high-volume production | Plasticizing time must exceed cooling time; ensure safe mold opening |

| Ejector Fly (Ejecting During Mold Opening) | Ejector starts pushing parts before mold fully opens | Speeds up ejection and accelerates overall molding rhythm | Low to Medium (must choose between ejection or core pull if shared circuits) | Mass production; simple products without delicate surfaces | Confirm safe early demolding; choose between Ejector Fly or Core Pull Fly |

| Core Pull Fly (Core Pulling During Mold Opening) | Core pulling actions proceed during mold opening | Eliminates core pull waiting time, improving cycle efficiency | Medium (requires careful side-action design and hydraulic planning) | Products with sliders or side cores | Ensure safe disengagement of core; cannot activate with Ejector Fly simultaneously |

- Segmented Injection Speeds: Prevents defects such as flash or short shots.

- Holding Time Tuning: Based on shrinkage and wall thickness.

- Mold Open Speed Control: Fast open with slow stop for accuracy and speed.

- Motion Overlap: Combine mold open and ejector operations.

- Ensure even cooling in key areas.

- Use temperature controllers for heat stability.

- Add dual-loop or thermal-balanced water channels.

- Adopting Microcellular Foam Injection Molding Technology

This advanced foaming method introduces supercritical fluid (such as N₂ or CO₂) into the polymer melt to form a fine and uniform cellular structure. It brings the following benefits:- Shortens Cooling Time:

- Reduces Part Weight and Injection Pressure:

- Improves Dimensional Stability and Warpage Resistance:

- Foamed materials have lower density, which enhances their thermal conductivity.

- Eliminates the need for full-thickness cooling—allowing earlier demolding.

- Typically reduces cooling time by 20–30%.

- Ideal for structural components or non-density-critical shells (e.g., logistics containers, tool housings).

- Lowers required injection pressure and clamping force, enabling quicker mold movements.

- Micro-bubbles balance internal stress and enhance part accuracy.

Further reading: Microcellular Foam Injection Molding: Achieving Maximum Weight Reduction and Dimensional Stability

- Synchronized Robotic Arm Part Removal: Coordinates with mold opening to reduce wait time and improve safety and consistency.

- Integrated Gate Cutting, Packaging, and Assembly: Post-mold processes, such as trimming and packing, can now occur in parallel with mold operations, reducing the overall production cycle.

- Dual-Slide or Rotary Table Systems (in Vertical Injection Machines): A/B station operations enable one side to eject while the other side injects—minimizing downtime through continuous workflow.

- In-Mold Labeling (IML): Applies labels directly during the injection process, eliminating the need for secondary operations.

- Smart Factory Management System

- Continuously track parameters such as cycle time, injection pressure, holding pressure, mold temperature, and mechanical actuation timing.

- Detect cycle anomalies and send instant alerts for early intervention and traceability.

- Remote Diagnostics Support: Enables off-site troubleshooting during machine faults or molding defects, effectively reducing machine downtime and improving operational efficiency.

Cycle Time refers to the total time required to complete one full injection molding process—from the start of mold closing to the start of the next identical cycle. It includes

Cycle Time is typically measured in seconds. The general formula is:

In practice, some customers use the cycle summary on the machine’s interface or analyze it via the controller or cycle monitoring system.

Example breakdown:

- Mold Close: 1.5 s

- Injection: 2.0 s

- Holding: 3.0 s

- Cooling: 15.0 s

- Mold Open: 1.2 s

- Ejection: 1.3 s

- Total Cycle Time = 24 seconds

There is no fixed “standard” cycle time—it varies greatly depending on several factors:

Key Influencing Factors

- Part size and wall thickness – thicker parts require longer cooling.

- Number of cavities – multi-cavity molds may extend ejection or mold open time.

- Plastic material properties – e.g., PA and PC cool more slowly than PP or PE.

- Mold cooling efficiency – well-designed cooling circuits reduce cycle time.

- Use of automation – robots, quick-change molds, and advanced controllers enhances efficiency.

| Application Type | Common Cycle Time Range |

|---|---|

| Small parts (caps, connectors) | 10–20 seconds |

| General appliances, auto parts | 25–45 seconds |

| Thick-walled, large products | 60–90 seconds |

In practice, when excluding cooling time and describing only the mechanical movements, we refer to the Dry Cycle Time.

It indicates the machine’s baseline mechanical capability.

Dry Cycle Time is the mechanical cycle time for:

This test excludes the mold, material, injection, and cooling steps, and reflects the minimum motion time.

- Larger machines have longer dry cycles due to:

- Smaller machines have faster dry cycles due to shorter motion travel and lighter mold plates.

- Longer stroke distances

- Heavier platens

Cycle time optimization in injection molding isn’t about tweaking one parameter—it’s a comprehensive, system-level integration.

As discussed throughout this article, true cycle time efficiency involves:

- Motion synchronization and speed segmentation

- Microcellular foam molding and direct drive plasticizing systems

- Efficient cooling channel designs

- In-mold automation

- Smart system data monitoring

Each element, when fine-tuned, contributes to tangible productivity gains and can make a meaningful difference in factory throughput and competitiveness.

- 10–30% increase in hourly output, improving delivery flexibility and market competitiveness

- Lower unit cost by reducing energy, labor, and material waste

- Smoother production rhythm, supporting better quality control and scheduling

- Supports ESG goals through energy-efficient upgrades and sustainable manufacturing technologies

Are you planning to optimize your injection molding performance, integrate automation, or establish a smart factory setup?

With over 40 years of injection molding expertise, Huarong provides professional equipment consulting and planning services to help you transition to high-efficiency, low-energy, intelligent manufacturing.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist.., Tainan City 72351, Taiwan