Microcellular Foam Injection Molding: A Complete Guide to Lightweight and Energy-Efficient Productio

2024-11-13 11:29:57

Microcellular foaming is transforming the future of plastic injection molding. As industries seek sustainable solutions and lower material consumption, microcellular foam injection molding offers a breakthrough in reducing part weight while preserving structural integrity. In this guide, we explore what microcellular foaming is, how it works, and why it's rapidly becoming the go-to process for modern manufacturers.

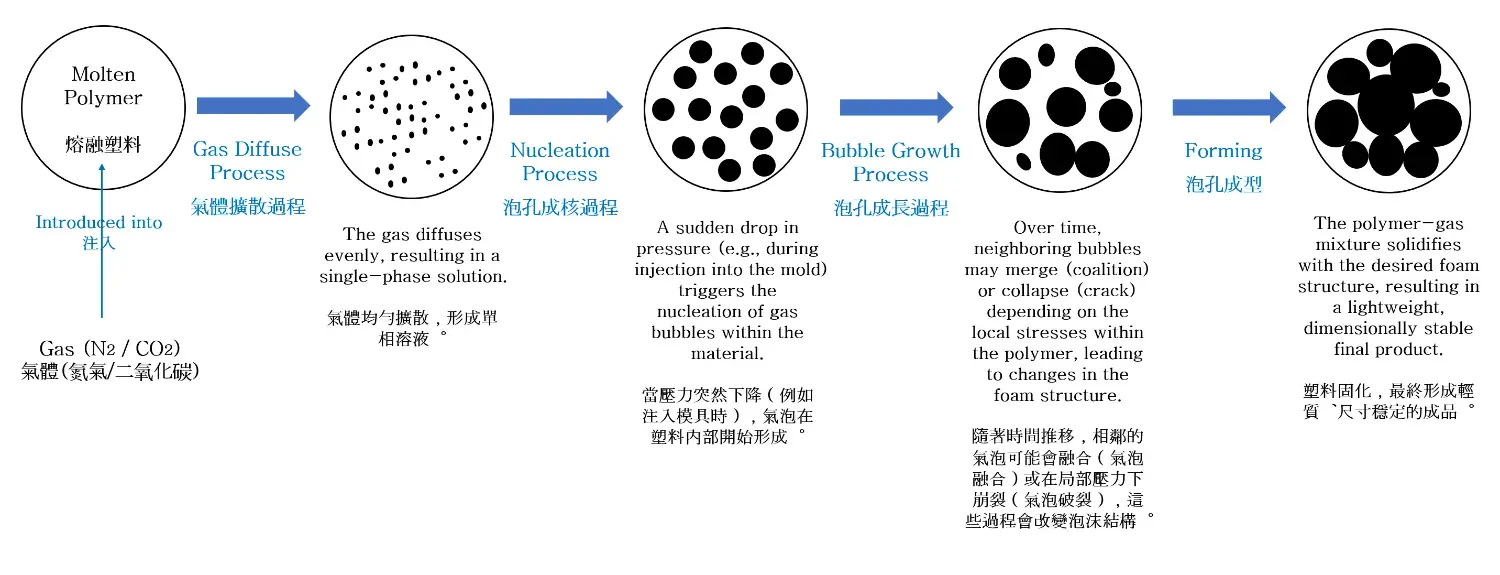

Microcellular foaming is a physical foaming injection technique that incorporates supercritical gas, typically nitrogen or carbon dioxide, into molten polymer during injection molding. The gas dissolves into the polymer melt under high pressure, forming a supersaturated mixture. When injected into the mold, the sudden pressure drop causes the nucleation of micro-scale bubbles, resulting in a uniform foam structure.

For manufacturers, this means:

- Lighter parts with excellent dimensional stability

- Faster cycle times due to reduced holding pressure

- Lower raw material costs and energy consumption

- A clean, eco-friendly alternative to chemical foaming methods

Further reading: Microcellular Foam Injection Molding Technology

Microcellular foam injection molding follows a similar sequence to traditional injection molding. Still, it introduces additional steps that enhance the final product's performance, particularly in terms of weight reduction and material efficiency. Here’s how the process compares to the traditional method, highlighting the unique elements of microcellular foam molding:

Further reading of traditional injection molding: What is Injection Molding? Processes, Benefits, and Applications

Step 1: Clamping

The process starts with clamping, where the two halves of the mold are pressed together using a clamping unit. This step ensures that the mold stays securely closed during the injection phase. However, a key difference is that microcellular foam molding requires much less clamping force due to the foaming action. The decreased clamping force saves energy and enables the production of larger parts on smaller machines, thereby reducing costs.

Step 2: Injection with Gas Dissolution

In traditional injection molding, plastic granules or pellets are melted and injected into the mold cavity under high pressure. However, in microcellular foam injection molding, a supercritical gas, nitrogen or carbon dioxide, is introduced into the molten plastic during the injection phase. This process, known as gas dissolution, allows the gas to dissolve into the polymer melt evenly. The presence of gas reduces the density of the material, offering the potential for lightweight yet strong parts.

Step 3: Nucleation and Reduced Dwelling

In traditional injection molding, the dwelling (holding) phase is required to compensate for material shrinkage and to keep the cavity fully packed, which increases cycle time and energy consumption.

In microcellular foam injection molding, the nucleation and growth of microcells inside the polymer provide an internal packing effect. Because of this, the required holding pressure and holding time can be significantly reduced, and in some cases the conventional holding stage can be shortened to a minimum. This reduction in high-pressure dwelling directly lowers energy consumption and shortens the overall cycle time.

Step 4: Cooling and Cell Growth

In both processes, the plastic begins to cool as soon as it is injected into the mold cavity. During this stage in Microcellular Foam Injection Molding, the formed cells (bubbles) expand uniformly as the material cools. This cell growth reduces the overall density of the part while maintaining its structural integrity. The cooling time may be slightly shorter in microcellular molding due to the presence of gas bubbles, which can improve production efficiency.

Step 5: Mold Opening

After the plastic part has cooled and solidified, the mold is opened, just like in traditional molding. The clamping mechanism releases, and the mold halves separate, revealing the newly formed part. Microcellular foam parts have a lower density, resulting in less material shrinkage than traditional solid parts. This results in improved dimensional stability and reduced post-mold defects.

Step 6: Ejection

The cured part is ejected from the mold cavity in the final stage of the process. Like the traditional process, an ejector pin is used to push the part out of the mold. The primary difference here is that microcellular parts often require less force during ejection due to the material's reduced density and foamed nature, resulting in smoother ejection with fewer defects. Trimming of excess material may still be necessary, but microcellular parts tend to have less material waste due to their efficient use of raw materials.

Because this technology forms microcellular bubbles within the polymer, the injection molding process has a few core characteristics that set it apart from traditional injection molding:

- Weight Reduction and Material Savings:

The primary benefit is a significant 15%-20% weight reduction without compromising mechanical strength. By reducing the amount of plastic used in each part, manufacturers can significantly reduce their raw material costs. - Dimensional Stability and Part Quality:

After introducing microcells, the parts produced exhibit excellent dimensional stability. - Shorter Cycle Time Reduction and Higher Process Efficiency:

Because the holding pressure and holding time can be greatly reduced, microcellular foam injection molding shortens the overall cycle time. Combined with lower clamping force and reduced material usage, this leads to higher productivity and lower energy consumption per part. - Clamping Force and Machine Size Optimization:

The foaming process reduces the clamping force required compared to traditional injection molding, allowing manufacturers to produce larger components on smaller machines and at lower costs. The lower internal pressure in microcellular foaming reduces mold wear and tear, thereby extending the mold's service life and allowing for longer production runs before refurbishment or replacement. - Environmental Benefits (Sustainability and Recycling):

This process reduces energy consumption by minimizing material usage and shortening cycle times, making it more environmentally friendly than traditional molding. Additionally, unlike chemical foaming methods, microcellular foam injection molding is a physical forming method that does not leave behind harmful residues, making the product more environmentally friendly and suitable for recycling back into the production stream.

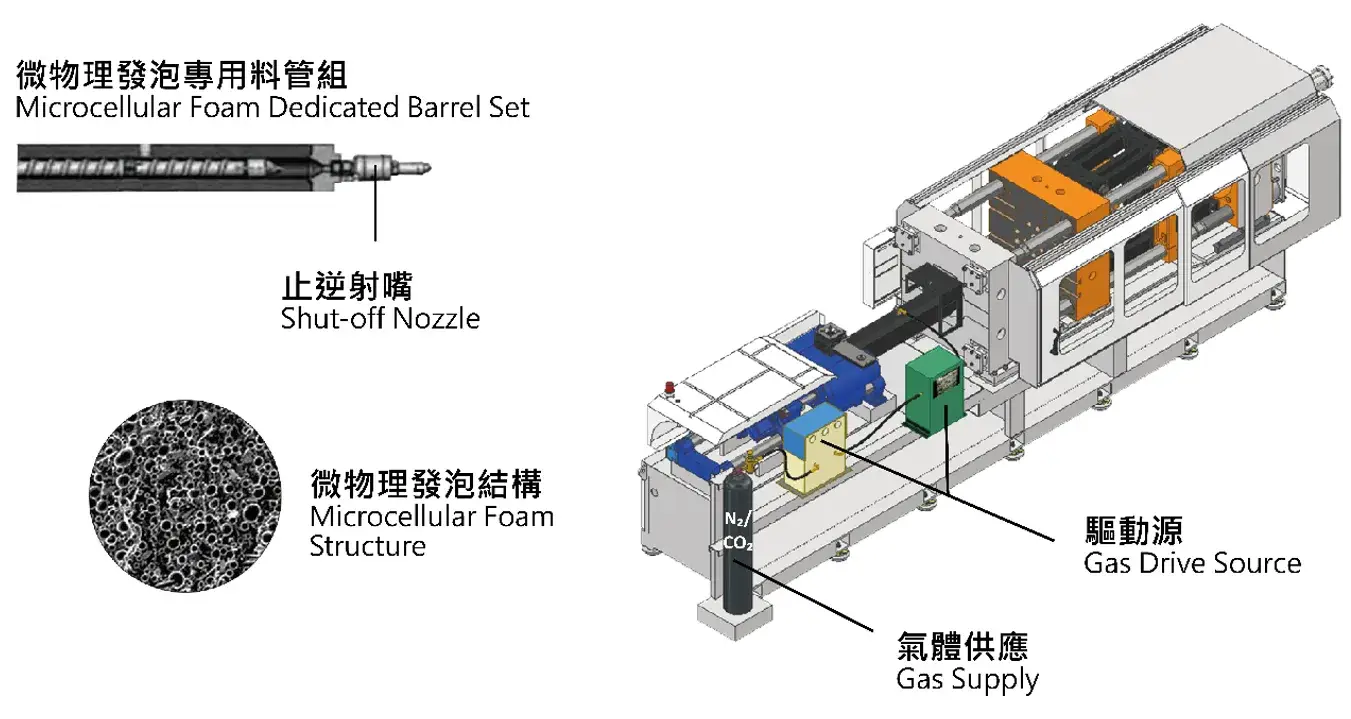

To implement microcellular foam injection molding, manufacturers typically do not need a completely new machine. Instead, a stable servo-hydraulic or high-performance injection molding machine can be upgraded with:

| Component | Function |

|---|---|

| Supercritical Gas Supply | Provides precise nitrogen or CO₂ injection at controlled pressure. |

| Gas Pressure Control System | Ensures accurate gas flow and stability during the plasticizing phase. |

| Foam-Optimized Screw & Barrel | Facilitates uniform gas dissolution and mixing with polymer melt. |

| Shut-Off Nozzle | Prevents premature gas release during injection to maintain foam quality. |

Microcellular Foam Injection Molding is highly versatile and is used in a range of industries, including:

- Automotive and EV Components: Ideal for interior trim, structural brackets, and modules where weight reduction directly contributes to improved fuel efficiency or EV driving range, without sacrificing stiffness or durability.

- Consumer Electronics and Home Appliances: Used for housings of handheld devices, small appliances, and tools that require a balance of strength, dimensional accuracy, and light weight, improving ergonomics and portability.

- Packaging and Industrial Components: Enables lighter crates, tray,s and protective packaging, reducing material usage while maintaining mechanical protection and stacking strength.

| Method | Description | Key Applications | Advantages | Limitations |

|---|---|---|---|---|

| Physical Foaming (e.g. microcellular foaming) | Inert gases like nitrogen or CO₂ are dissolved into the polymer melt. When pressure drops during injection, microcells form. | Automotive, electronics, structural components | Uniform microcellular structure, reduced material use, recyclable, no chemical residues | Requires precise control of pressure and temperature |

| Chemical Foaming | Blowing agents decompose thermally and release gas to create foam within the melt. | Consumer goods, insulation, packaging | Simple process, compatible with various thermoplastics | Residual chemicals may affect recyclability; can emit VOCs |

| Structural Foam Molding | Combines foaming with thicker-walled parts, often using low-pressure molding with physical or chemical agents. | Large components like panels, furniture, pallets | Strong, rigid parts with internal cellular structure | Slower cycle times, less precision for tight tolerances |

Is microcellular foam injection molding suitable for visible, high-gloss parts?

In most cases, microcellular foam injection molding produces a slightly matte or satin surface due to the internal cell structure and reduced packing pressure. For textured or grained surfaces, this is usually acceptable and often not noticeable. However, for Class-A, high-gloss exterior surfaces, solid injection molding or a skin–core–skin (co-injection) approach is generally preferred if a perfectly glossy appearance is required.

How much weight reduction can I typically get with microcellular foam?

Typical weight reduction with microcellular foam injection molding is in the range of 10–20%, depending on the material, wall thickness, and part design. With optimized part geometry and process settings, higher weight reduction may be achievable, but it is important to balance density reduction with mechanical performance and surface requirements. A realistic engineering target is usually set after preliminary trials and part simulation.

Can I retrofit my existing injection molding machine for microcellular foaming?

In many cases, an existing injection molding machine can be retrofitted for microcellular foam injection molding, provided that the machine has stable injection control, sufficient plasticizing capability, and good repeatability. A typical retrofit includes adding a supercritical gas supply and dosing unit, a pressure control system, a suitable shut-off nozzle, and integrating foaming parameters into the controller. Older or highly worn machines may struggle to maintain process stability, so it is recommended to evaluate the machine condition and discuss feasibility with the equipment supplier.

What materials can be used for microcellular foam injection molding?

Most conventional thermoplastics can be used in microcellular foam injection molding, including PP, ABS, PC, PC/ABS blends, PS, PBT, and certain grades of PA, among others. Filled and reinforced materials (such as glass-fiber reinforced resins) can also be foamed, but they may require more precise process tuning to achieve a uniform cell structure. Material rheology, thermal stability, and moisture control all play important roles in achieving consistent foaming quality.

What is the difference between microcellular foam injection molding and chemical foaming?

Microcellular foam injection molding is a physical foaming process that uses supercritical gases (typically nitrogen or carbon dioxide) dissolved directly into the polymer melt, creating a fine and uniform microcellular structure during pressure drop. Chemical foaming, on the other hand, relies on chemical blowing agents that decompose under heat to generate gas inside the melt. While chemical foaming is relatively simple to implement, it can leave residues, affect recyclability, and offer less precise control over cell size and distribution. Microcellular foam injection molding provides cleaner processing, better dimensional control, and is generally more suitable for applications with higher performance and sustainability requirements.

As global industries pursue sustainability, lightweighting, and manufacturing efficiency, microcellular foaming is emerging as a transformative technology in injection molding. By using a clean physical foaming process, manufacturers can reduce material consumption by up to 20%, shorten cycle times, and maintain high dimensional accuracy—all while supporting environmental goals.

From automotive interiors to consumer electronics and industrial components, microcellular foam injection molding delivers a competitive edge in both performance and cost. Its versatility, recyclability, and compatibility with high-throughput production make it a cornerstone for next-generation plastic part manufacturing.

Ready to Explore Microcellular Foam Injection Molding with Huarong?

Share your part drawings, material, and machine tonnage requirements with our team. We will help you evaluate machine sizing, foaming feasibility, and expected weight reduction, and recommend a complete solution including SCF system, injection molding machine, and automation if needed.

- Group Name: Huarong Group

- Brand: Huarong, Yuhdak, Nanrong

- Service Offerings: Injection Molding Machine, Vertical Injection Molding Machine, Injection Molding Automation

- Tel: +886-6-7956777

- Address: No.21-6, Zhongzhou, Chin An Vil., Xigang Dist., Tainan City 72351, Taiwan

- Official Website: https://www.huarong.com.tw/