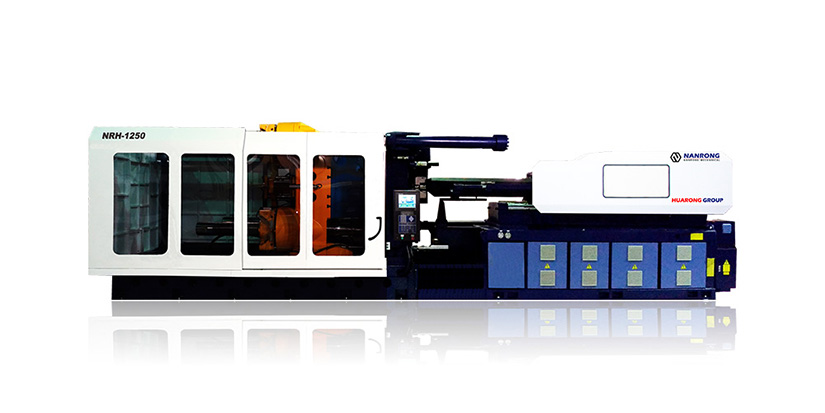

Two platen injection molding machine – NRH series

ー Medium to large-sized plastic molding machine, significantly reducing the length of medium to large-sized equipment, with a longer mold opening stroke.

The NRH series of two-platen injection molding machines are designed to meet the rigorous requirements for molding complex, large-sized plastic parts. With clamping forces ranging from 500 tons to 5000 tons, this machine is capable of handling various applications, from automotive components such as bumpers and dashboards to pallets exceeding 3000 tons. It is suitable for the production of large objects in industries such as automotive manufacturing and consumer goods.

Machine Features

ー Enhancing precision and robustness through innovative patented designs

The two-platen machine is one of Huarong Group's core products. We focus on the machine's performance and quality and prioritize our customers' production needs. We are committed to optimizing machine performance to make it stand out in the injection molding machine market and provide the best injection molding solutions.

Patented Moving Platen Positioning Device

ー Patent M636571

The two-platen injection molding machine is equipped with jig and gauge positioning modules to quickly determine the coaxiality of the two platens, ensuring precise and fast assembly.

Optimized Direct-pressure Hydraulic Cylinder

Four sets of double half nuts, direct pressure cylinders, and tie-bar threads are precisely positioned, along with a synchronized hydraulic design, ensuring balanced force distribution during equal stretching and providing uniform clamping force.

Temperature Monitoring Design

Independent temperature monitoring of core components with real-time notification of abnormal temperature rise, ensuring effective lubrication of parts to prevent irreversible damage.

Timed Sequential Valves Design

Adopts a distribution valve, combined with sensors, to ensure that lubricating oil reaches every lubrication point.

Patented Suspended Tie-bar Bearing Module

ー Patent M634662

The two-platen injection molding machine is equipped with a suspended tie-bar bearing module.

This module ensures that the tie bar does not sag or deform, improving previous wear and noise issues. The module effectively reduces frictional resistance between the moving platen and the tie bar, making maintenance and repair easier.

Patented Inner Supporting Sliding Module

ー Patent M578643

Related adjustment structures are located on the outer side of the machine for easy maintenance while ensuring safety and convenience. Features high loading and two-way guiding functions.

Coupled with block positioning modules and precision machining requirements for parts, the parts are assembled with precise positioning without the need for manual adjustment, effectively enhancing assembly efficiency and accuracy.

Patented Outward-opening Safety Door

ー Patent M257955

Designing a two-stage safety door with a focus on humanization, simplification, and uniqueness. Easy opening/closing, spacious opening, convenient, and time-saving for mechanical maintenance.

Patented Groove Design with Tie-bars

ー Patent 313046、334924、428536

Innovative design, such as necking down the tie-bar in the platen section, eliminates the shear force generated by the platen on the clamping tie-bar, avoiding its fracture.

Autonomous Detection Functionality

Regular alerts to customers during the production cycle prompt them to use an inspection jig and gauge to check the height of the moving platen center to prevent abnormal coaxiality of the two platens.

For the optional function of collecting, calculating, and analyzing stable production parameters of the machine, customers only need to set the error range and automatically monitor 13 production parameters during the production process. When parameters deviate during production, early notification of anomalies is provided, along with the abnormal items and data for users to adjust in real time, reducing the probability of defects and machine damage.

Patented Tie-bar Disassembles Function

ー Patent M481124

The optional function of the operating-side tie bar (upper) is detachable, allowing molds to enter the clamping area from the front side of the machine.

This overcomes the limitation of insufficient vertical space in the workshop. This reduces the required space for hanging the upper and lower molds, allowing for flexible utilization within limited hanging space.

Advantages of Two-Platen Injection Molding Machine

ー Shortening the Length of Large Equipment

The equipment design of two-plate machines shortens the dimensions by approximately 20% to 30% compared to toggle-type machines. The mold clamping cylinders adopt an embedded design, effectively reducing the machine's length, saving both length and placement space, and simultaneously improving the workshop's utilization rate.

ー Extended Mold Opening Stroke

Two-platen machines feature rapid and fully automatic mold adjustment functions, making operation more convenient. The equipment can also extend the mold opening stroke according to production needs, ensuring flexibility and versatility of the machinery.

Machine Applications

ー Applied in various industries, including automotive, household appliances, electronics, and other medium- to large-sized plastic products

Automotive Parts: Bumpers, dashboards, interior components.

Public Facilities: Outdoor garbage bins, road signs, traffic cones.

Logistics Industry: Pallets, plastic crates, transport boxes.

Household Appliances: Televisions, refrigerators, screens, blenders.

Why Choose Huarong?

ー Your Best Injection Molding Partner

Huarong is dedicated to being your most trusted injection molding partner with a customer-first approach. Leveraging extensive production experience and technological advantages, we provide a complete range of injection machine models, automation, and smart services while adhering to equipment simplicity in maintenance, high precision, and stability. This enables us to consistently deliver high-quality products and services to our customers.

ー Meeting Your Injection Molding Needs

As one of the leading injection molding machine manufacturers, we are highly acclaimed by our customers. We continuously strive for optimal quality on our two-platen machines while ensuring precision and stability in our equipment. This not only helps to reduce downtime and improve production efficiency but also earns us multiple patents. Choose Huarong for quality and reliability.

Successful Cases of Two-Platen Machines

Product: Pallets

Pallets are essential tools in logistics and warehouse management, facilitating the stacking of goods, saving storage space, and enabling convenient, safe transportation and storage. So why choose the injection molding process for plastic pallets?